2.

The sprinkler uses a fast-response thermal element and

is available with a temperature rating of 155°F (68°C), 175°F

(79°C), or 200°F (93°C). Model SWC cover plates include a

conical concealed cover plate that is attached to a skirt with

temperature sensitive solder. Operation of the Model SWC cov-

er plate occurs when the solder melts due to an increase in the

surrounding temperature, allowing the cover plate to fall away

and exposing the Model DH80 Dry sprinkler. Model SWC cover

plates are available with a Temperature Rating of either 135°F

(57°C) for use with Ordinary Temperature Classication [155°F

(68°C)] sprinklers or 165°F for use with Intermediate Tempera-

ture Classication [175°F (79°C) and 200°F (93°C)] sprinklers.

Model DH80 dry sprinklers have a special wax llet placed

in the gap between the cup that supports the bulb and the

wrenching boss. This wax will not interfere with the operation of

the sprinkler, and it prevents contaminants from entering the in-

ternal portion of the drop nipple. The wax must not be removed.

Application

The Model DH80 Dry sprinkler is a horizontal sidewall dry

sprinkler intended for installation in light hazard occupancies

in accordance with NFPA 13. These sprinklers are designed

to provide re protection in long and narrow spaces such as

hallways, corridors, decks and portions of rooms up to 28 feet

(8.5 m) wide and 14 feet (4.3 m) long. They are rated for 175

psi (12 bar) and can be mounted between 4 and 12 inches

(102 and 305 mm) down from the ceiling. Model DH80 Dry

sprinklers may be installed on wet-pipe sprinkler systems in ac-

cordance with Fig. 8, as well as dry-pipe and preaction sprin-

kler systems.

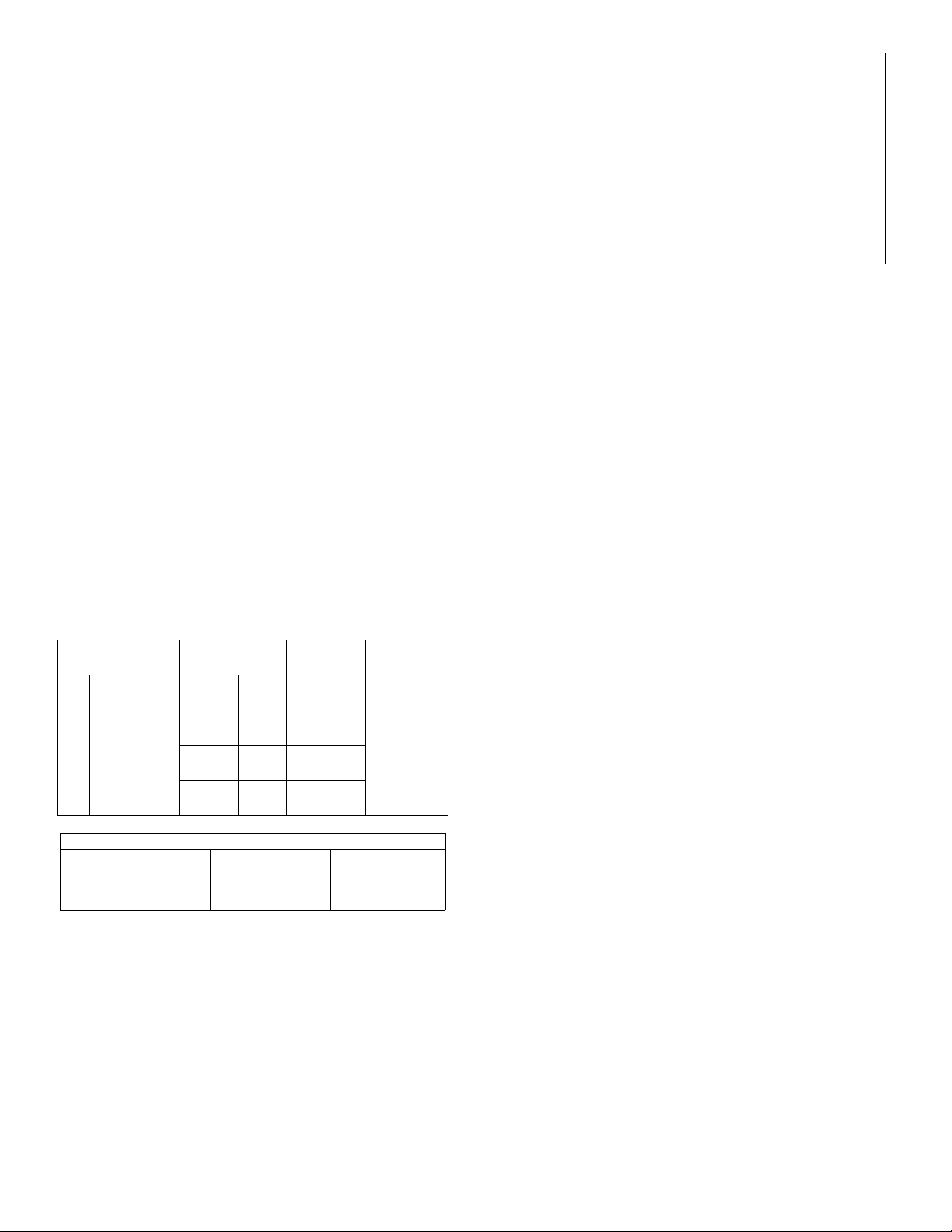

Technical Data:

Nominal

K-Factor Thread

Size

Temperature

Rating Maximum

Ambient

Temperature

Sprinkler

Identication

Number

(SIN)

US Met-

ric Sprinkler SWC

Cover

8.0 115

1” NPT

or

ISO

7-1R1

155°F

(68°C)

135°F

(57°C)

100°F

(38°C)

RA5532

175°F

(79°C)

165°F

(74°C)

150°F

(66°C)

200°F

(93°C)

165°F

(74°C)

150°F

(66°C)

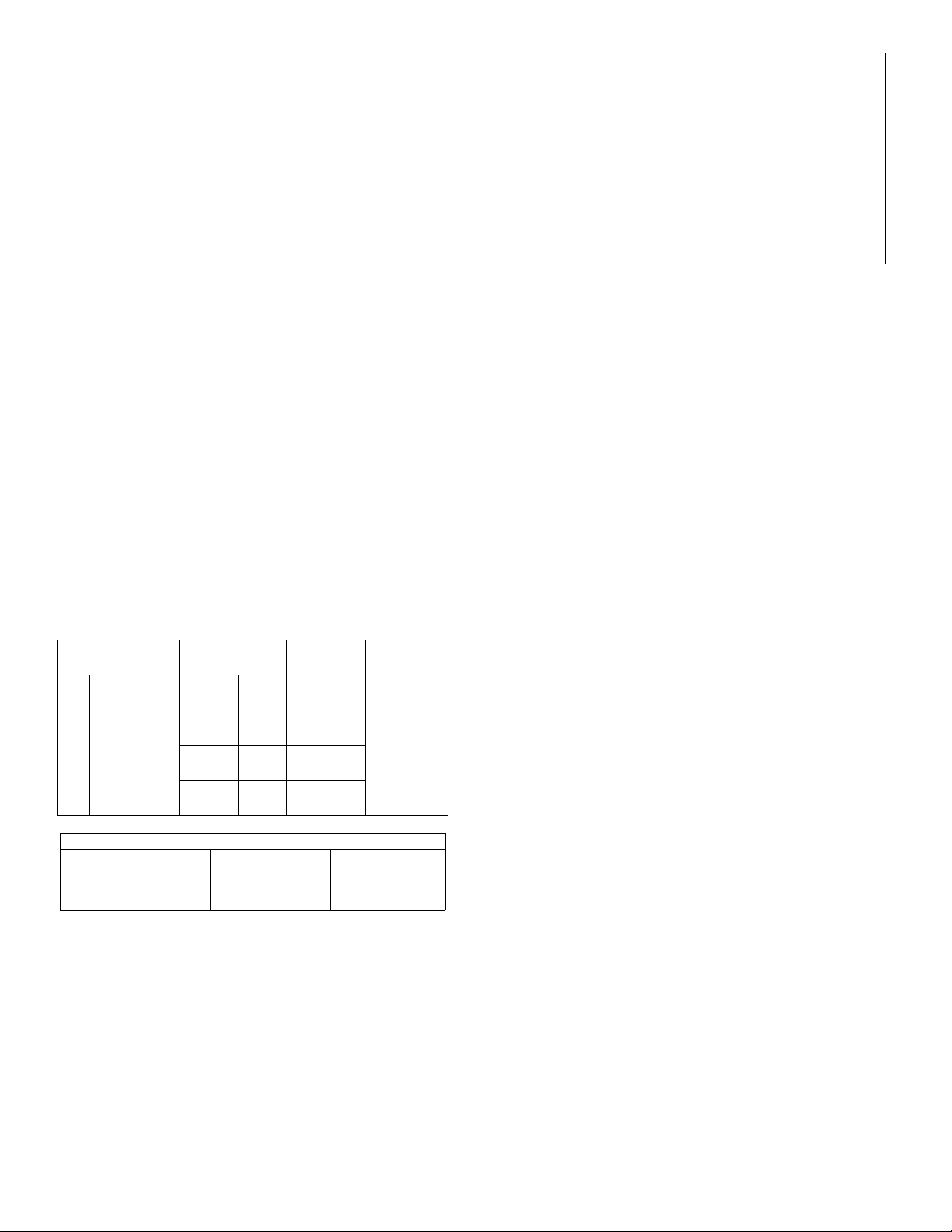

Required Minimum Flow Rate and Pressure

Maximum Coverage

Area Width x Length

ft x ft (m x m)

Flow Rate

gpm (L/min)

Pressure

psi (bar)

28 x 14 (8.5 x 4.3) 40 (151) 25 (1.7)

Installation Instructions

Reliable Model DH80 dry sidewall sprinklers may be in-

stalled in ductile or malleable cast iron threaded tees, or CPVC

tees and adapters upon verication that the sprinkler inlet tting

does not interfere with the interior of the tting (see Figure 9).

DO NOT install Reliable Model DH80 dry sidewall sprinklers

into elbows or couplings, welded outlets, mechanical tees, or

gasket sealed CPVC ttings.

Dry sprinklers connected to wet pipe systems must be in-

stalled as indicated in Figure 8 and as required by NFPA 13 with

the Exposed Minimum Barrel Length located in a heated area.

A clip is provided to protect the glass bulb thermal element

from damage. The clip is factory installed on the sprinkler. The

clip should remain in place during installation of the sprinkler

and be removed when the sprinkler system is placed in service.

Model DH80 Dry sprinklers with the Model FP recessed es-

cutcheon or the Model SWC cover plate are also supplied with

a cap that can be used to provide additional protection for the

sprinkler during painting or nishing. The cap can be installed

without removing the clip. Both the cap and the clip must be

removed when the sprinkler system is placed in service.

Use the following steps for installation:

1. The centerline of the Model DH80 Dry sprinkler must be

installed between 4-5/8” (118 mm) and 12-5/8” (321 mm)

vertically below the nished ceiling so that the top of the de-

flector is not less than 4“ (102 mm) or more than 12” (305

mm) from the nished ceiling. A hole must be cut in the wall

directly in-line with the outlet of the tee. See the Installation

Data table for the recommended hole diameter based on

the escutcheon or cover plate option selected.

2. Apply pipe joint compound or Polytetrafluoroethylene

(PTFE) tape to the threads of the sprinkler’s inlet tting.

3. Install the sprinkler in the tee using the installation wrench

specied in the Installation Data table. The Model F3R

wrench is designed to be inserted into the groves in the

sprinkler’s wrench boss as shown in Fig. 3. The Model

XLO2 wrench is designed to t into the cup and engage the

wrench boss as shown in Fig. 2. Do NOT wrench any part

of the sprinkler assembly other than the wrench boss. When

inserting or removing the wrench from the sprinkler, care

should be taken to prevent damage to the sprinkler. The

sprinkler is then tightened into the pipe tting to achieve a

leak free connection. The recommended minimum to maxi-

mum installation torque is 22-30 lb-ft (30 – 40 N-m).

3a. Alternatively, where access to the outer tube of the sprinkler

is available, the Model DH80 Dry sprinkler may be installed

using a pipe wrench. The pipe wrench shall only be per-

mitted to interface with the steel outer tube portion of the

sprinkler (Item #8 in Fig. 10). Do NOT wrench any other por-

tion of the sprinkler assembly. A pipe wrench can install the

sprinkler into the tting with a large amount of torque; con-

sideration should be given to the need for future removal of

the sprinkler because the installation torque will have to be

matched or exceeded to remove the sprinkler. The recom-

mended minimum to maximum installation torque is 22-30

lb-ft (30 – 40 N-m).