iii

Table Of Contents

Features and Installation Highlights ...................................................................................................................1-1

Capabilities and Functions .................................................................................................................................................. 1-1

Compatible Devices ............................................................................................................................................................ 1-2

Important Installation Highlights (Installer Please Read)..................................................................................................... 1-2

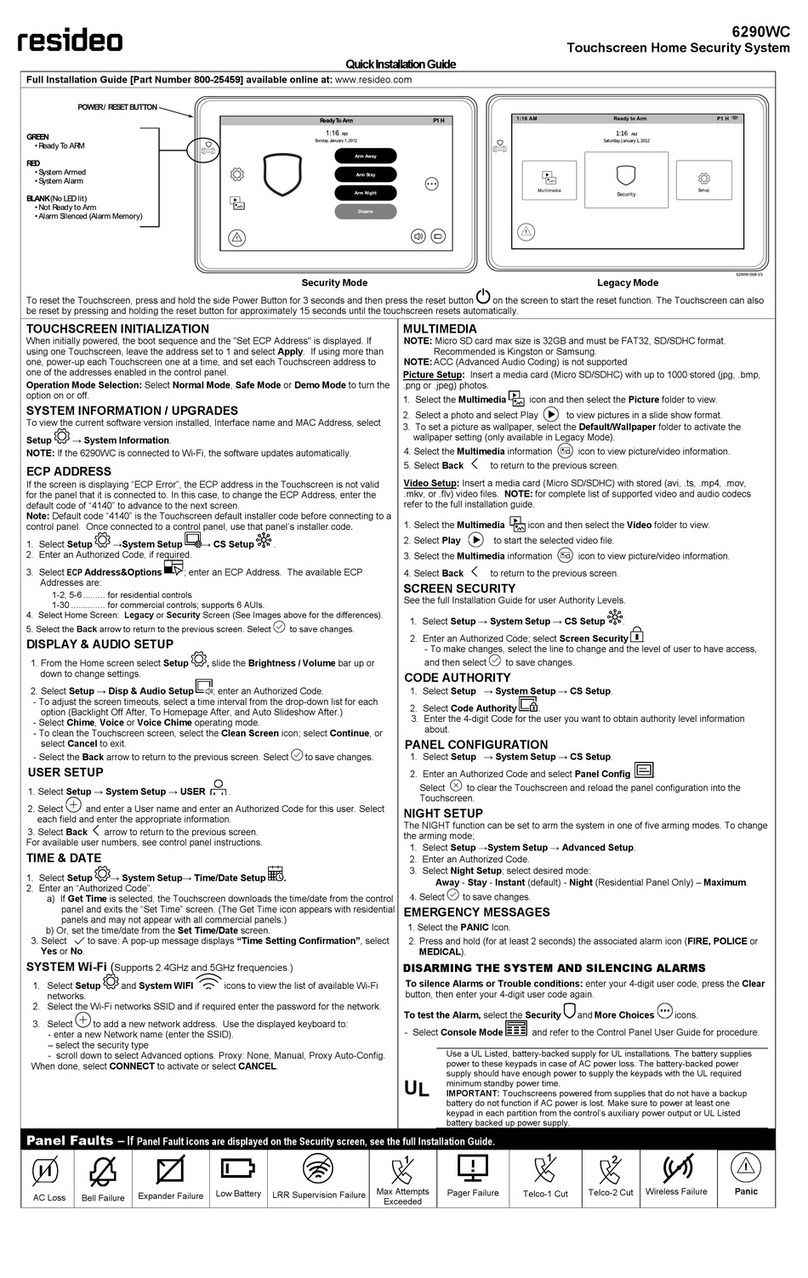

Mounting and Wiring the Control ........................................................................................................................2-1

Installing the Control Cabinet and PC Board....................................................................................................................... 2-1

Cabinet and Lock .......................................................................................................................................................... 2-1

Mounting the PC Board Alone (no RF Receiver)........................................................................................................... 2-1

Mounting Board with RF Receiver................................................................................................................................. 2-1

Auxiliary Device Current Draw Worksheet..................................................................................................................... 2-2

AC Power, Battery, and Ground Connections..................................................................................................................... 2-3

1321 Transformer.......................................................................................................................................................... 2-3

Battery Connections ...................................................................................................................................................... 2-3

Battery Saver Feature ................................................................................................................................................... 2-3

Earth Ground................................................................................................................................................................. 2-3

Sounder (Bell) Connections ................................................................................................................................................ 2-4

Basic Connections......................................................................................................................................................... 2-4

Supervised output ......................................................................................................................................................... 2-4

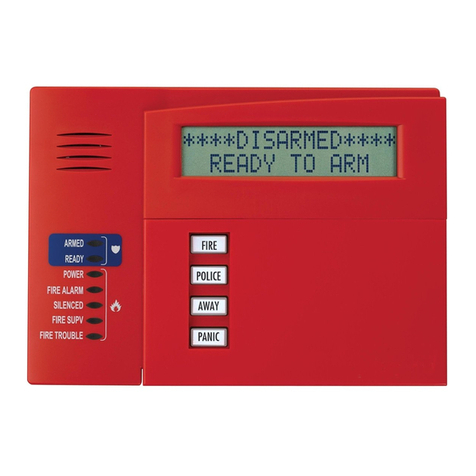

Connecting the Keypads and Other Addressable Devices.................................................................................................. 2-4

Connections .................................................................................................................................................................. 2-4

Supplementary Power (optional) ................................................................................................................................... 2-4

Keypad Notes................................................................................................................................................................ 2-5

Communication Device.................................................................................................................................................. 2-5

(Long Range Radio) Connections ................................................................................................................................. 2-5

Table of Device Addresses ................................................................................................................................................. 2-5

Hardwire Zones and Zone Expansion................................................................................................................................. 2-6

Hardwire Zones ............................................................................................................................................................. 2-6

Double-Balanced Zones................................................................................................................................................ 2-6

Zone Doubling ............................................................................................................................................................... 2-6

Smoke Detectors........................................................................................................................................................... 2-6

Smoke Detector Notes .................................................................................................................................................. 2-7

4219/4229 Expansion Zones......................................................................................................................................... 2-7

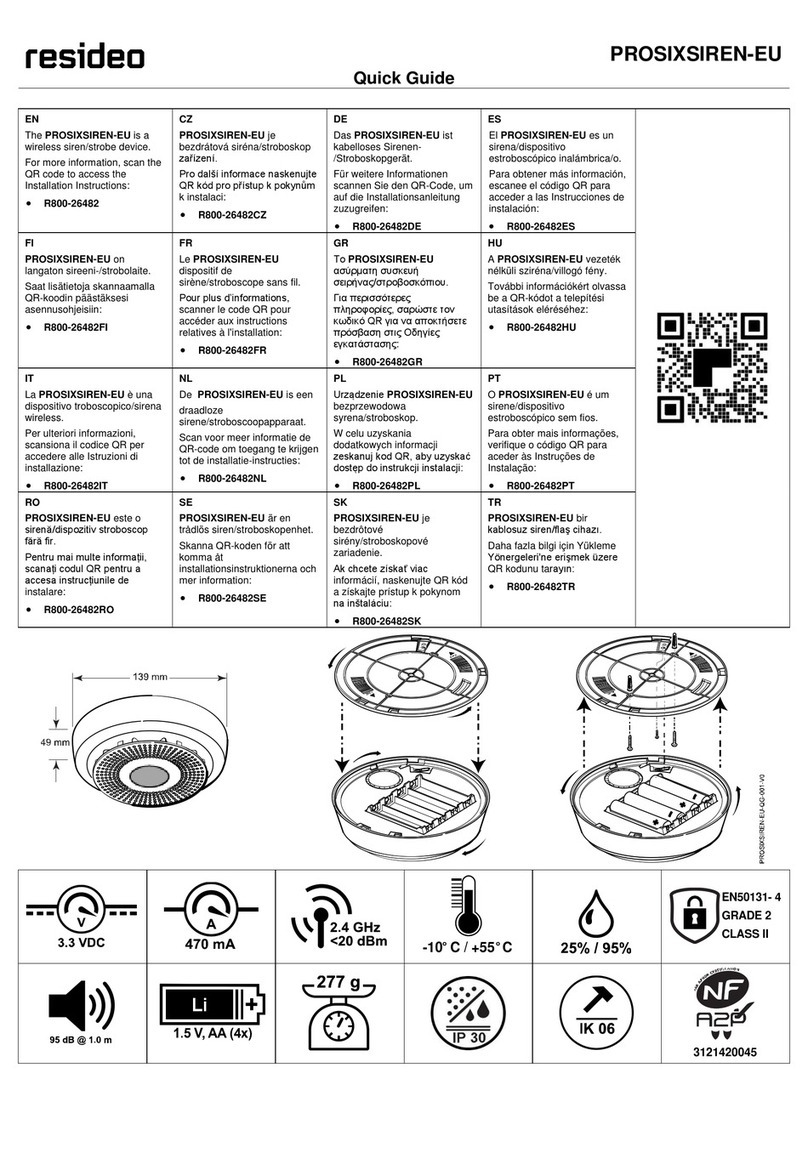

Installing the RF Receiver and Wireless Transmitter Zones ............................................................................................... 2-8

Compatible Receivers ................................................................................................................................................... 2-8

Receiver Connections ................................................................................................................................................... 2-8

RF Receiver Notes ........................................................................................................................................................ 2-8

Installing the Transmitters ............................................................................................................................................. 2-9

Transmitter Battery Life ................................................................................................................................................. 2-9

Connecting Relay Modules and Output Triggers .............................................................................................................. 2-10

4204/4229 Relay Modules........................................................................................................................................... 2-10

On-Board Triggers....................................................................................................................................................... 2-10

Phone Line and Audio Alarm Verification (AAV) Connections .......................................................................................... 2-11

Phone Line .................................................................................................................................................................. 2-11

Audio Alarm Verification Connections ......................................................................................................................... 2-11

Audio Alarm Verification Connections ......................................................................................................................... 2-12