English 2

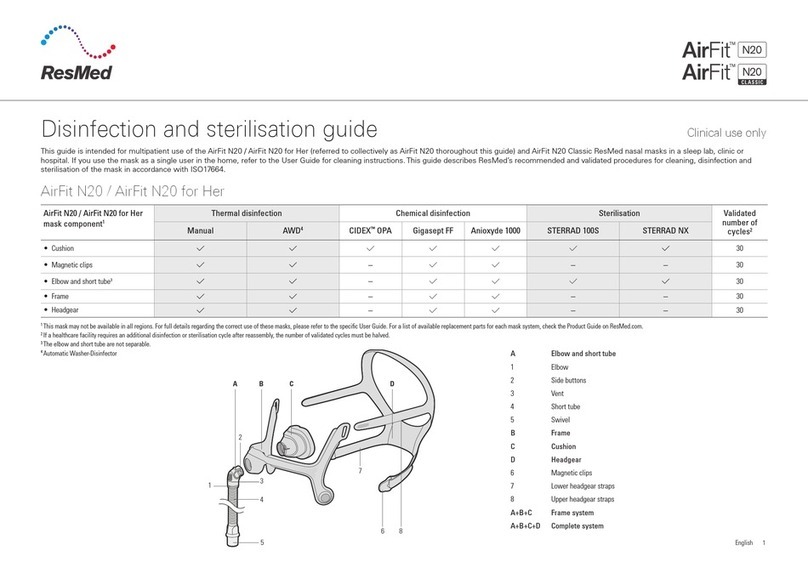

Validated disinfection and sterilization procedures

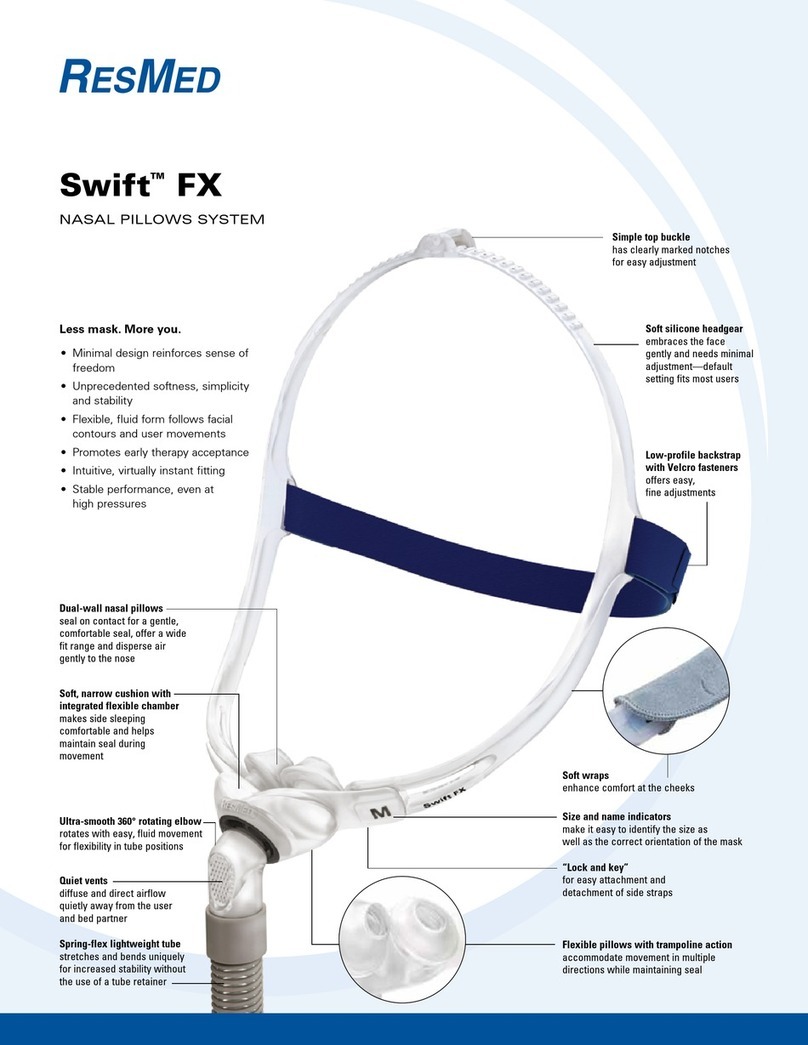

Disassembly Disassemble the mask according to the instructions in the User Guide. Magnetic clips must be removed from the lower headgear straps.

Cleaning and drying

Cushion / magnetic clips Multi-hole elbow and short tube Frame / headgear

1. Make a solution of Alconox®by diluting with drinking quality

water at 1%, ie, 10 g per liter, at 77-86°F (25-30°C), according

to the manufacturer’s instructions.

2. Whilst in the solution, thoroughly clean the mask component

with a soft bristle brush for 1 minute. Pay particular attention

to all crevices and cavities.

3. Rinse the component by agitating it vigorously in drinking

quality water, 5 liters per component at 77-86°F (25-30°C) for

1 minute.

Repeat the process by using fresh water for another 1 minute.

4. Inspect and if required, repeat washing until visually clean.1

5. Allow the component to air dry out of direct sunlight.

1. Make a solution of Alconox by diluting with drinking quality water

at 1%, ie, 10 g per liter, at 113-131°F (45-55°C), according to the

manufacturer’s instructions.

2. Soak the mask component in the solution for 5 minutes. Rotate all

connections three times around 360 degrees.

3. Whilst in the solution, thoroughly clean the component with a test

tube brush for an additional 1 minute. Pay particular attention to all

crevices and cavities.

4. Rinse the component by agitating it vigorously in drinking quality

water, 5 liters per component at 77-86°F (25-30°C) for 1 minute.

Repeat the process by using fresh water for another 1 minute.

5. Rinse the component under fast-running drinking quality tap water

(113-131°F (45-55°C)) from one end of the component, for 20

seconds. Repeat the process from the other end of the component.

6. Shake the component vigorously to remove excess water.

7. Inspect and if required, repeat washing until visually clean.

8. Allow the component to air dry out of direct sunlight.

1. Make a solution of Alconox by diluting with drinking quality

water at 1%, ie, 10 g per liter, at 68-86°F (20-30°C), according to

the manufacturer’s instructions.

2. Soak the mask component in the solution for 3 minutes.

3. Thoroughly clean the mask component with a soft bristle brush

for 2 minute while continuing to soak it in the solution.

Pay particular attention to all crevices and cavities.

4. Squeeze the component to remove excess solution.

5. To rinse the component, repeatedly squeeze it under running

drinking quality tap water at 68-86°F (20-30°C) for 30 seconds.

Repeat the process by using fresh water two more times.

6. Squeeze the component to remove excess water.

7. Inspect and if required, repeat washing until visually clean.1

8. Allow the component to air dry out of direct sunlight.

1 Failure to clean the mask component as indicated may result in inadequate disinfection and sterilization.

In the procedures below, only one of the following three disinfection or sterilization procedures needs to be performed.

Disinfection or

sterilization and drying

High level thermal disinfection High level chemical disinfection STERRAD Sterilization

Cushion / magnetic clips / multi-hole elbow and short tube /

frame / headgear Cushion Cushion

1. Fully immerse the mask component in a hot water bath using

a temperature-time combination, ensuring there are no air

bubbles:

Cushion / magnetic clips /

multi-hole elbow and short tube:

• 194°F (90°C) for 1 minute.

Frame / headgear:

• 199.4-203°F (93-95°C) for 10 minutes.

2. Remove the component from the hot water bath.

3. Shake the component to remove excess water.

4. Allow the component to air dry out of direct sunlight.

1. Fully immerse and soak the mask component in a commercially

available solution according to the manufacturer’s instructions

and agitate to ensure there are no air bubbles: For example:

• Ortho-phthalaldehyde 0.55% (eg, CIDEX OPA) at 68-77°F

(20-25°C) for 12 minutes

2. Rinse the component in drinking quality water, 7.5liters per

component:

• 68-86°F (20-30°C) for 1 minute

Repeat the process by using fresh water for two more times.2

3. Shake the component to remove excess water.

4. Allow the component to air dry out of direct sunlight.

1. Dry the mask component thoroughly.

If the component is wet, the sterilization cycle may fail.

2. Package the component prior to sterilization as described in the

manufacturer’s instructions for the STERRAD Sterilization System.

Note: The use of pouches is not recommended.

3. Sterilize the component by following the manufacturer’s instructions.

• STERRAD 100S: Short cycle (boosters not required)

• STERRAD NX: Standard or advanced cycle

4. Rinse and agitate in drinking quality water, 5 liters per component at

68-86°F (20-30°C) for 1 minute.

5. Shake the component to remove excess water.

6. Allow the component to air dry out of direct sunlight.

Inspection Perform a visual inspection of the component. If any visible deterioration is apparent (cracking, crazing, tears etc), the component should be discarded and replaced.

Slight discoloration of the silicone components may occur and are acceptable.

Reassembly Reassemble the mask according to the instructions in the User Guide.

Packaging and storage Store in a dry, dust-free environment away from direct sunlight.

Storage temperature: -4°F to 140°F (-20°C to 60°C).

2 Failure to adequately rinse the component may result in toxic levels of residual CIDEX OPA.