GB ‘Workmaster™’ DIELECTRIC - User Information

The safety footwear supplied by Respirex International Ltd complies with the EC Directive for Personal Protective Equipment

(Directive 89/686/EEC) and meets requirements according to the European harmonised standard EN ISO 20345:2011. The

electrical properties of the footwear complies with EN 50321:1999 (complete boot).

The DIELECTRIC boot will withstand 20,000 volts for 3 minutes on the complete boot, showing no leakage in excess of 5

milliamperes at 5 kV. Specication is designed to reduce the risk of interference with the heartbeat by electrical current passing

through the wearer. In addition, the Dielectric boot meets the requirements of ASTM F1117, withstanding 20kV for over three minutes.

Footwear is manufactured using materials which conform to the relevant sections of

EN ISO 20345:2011 for quality and performance. The footwear protects the wearer’s toes against risk of injury from falling

objects and crushing in a working environment.

Impact protection provided is 200 Joules.

Compression (crushing) resistance provided is 15,000 Newtons.

This footwear is tted with a vulcanised rubber sole for improved slip resistance in wet conditions that conforms to

EN13287:2004.

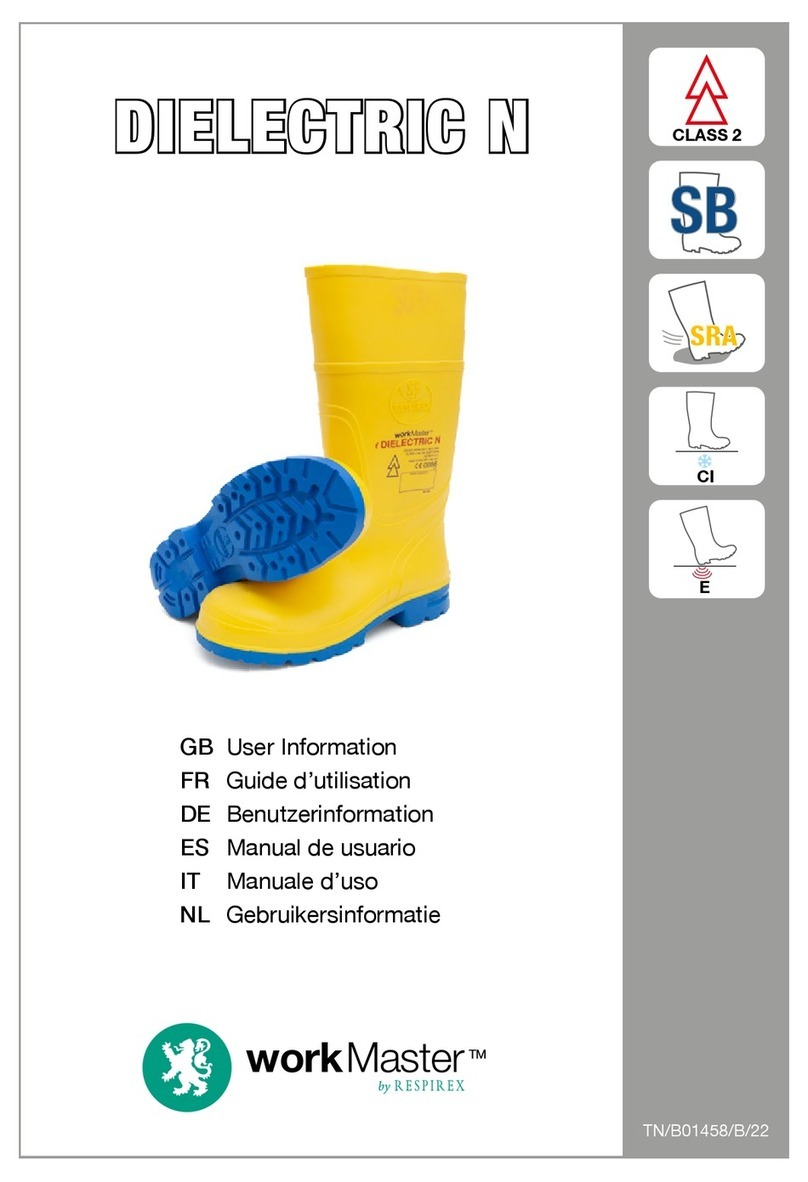

Marking denotes that the footwear is licensed according to PPE directive and is as follows:

• Manufacturer - See Sole

• CE - See upper CE Mark - Certicate issued by SGS United Kingdom Ltd, Weston-super-Mare, BS22 6WA.

Notied Body 0120

• EN ISO 20345:2011 - See upper Number of European Standard

• SB - See upper - SB denotes the boot meets the basic requirements of EN ISO 20345:2011 for all-polymeric (i.e. entirely

moulded) footwear

• I - See upper - Classication ‘I’ denotes electrically insulating footwear

• E - See upper - Classication ‘E’ denotes energy absorbing heel

• Double red triangle - See upper - denotes class 0 of EN 50321:1999 (suitable for live working)

• Size - See Sole - UK & European Marking.

• Date of Manufacture - See upper - Month and Year

It is important that the footwear selected is suitable for the protection required and the working environment. The suitability of

the boots for a particular task can only be established once a full risk-assessment has been carried out.

PRODUCT CARE

Please ensure that all strong chemicals or other types of contamination are washed o as soon as possible. Serious damage

may result if certain chemicals, fats & oils are not removed or if the footwear cleaned regularly after use.

If the footwear becomes cut or damaged, it will not continue to give the specied level of protection. To ensure that the wearer

continues to receive maximum protection, any damaged footwear should be immediately replaced.

The boot lining should also be wiped with a mild detergent from time to time. Do not expose the boots to temperatures in

excess of 50°C when drying.

The packaging of the footwear used for transportation to customers is designed to protect the boots until they are used.

Storage in extremes of temperatures may aect its useful service life and should be avoided.

LIMITATIONS OF USE

The Workmaster Dielectric boot is only suitable for use within a temperature range of -20°C to +60°C. Alternative footwear

should be utilised for applications outside this range.

The Workmaster Dielectric boot has a shelf-life of 10 years. Any boots that have remained unused for a period of 10 years

should be replaced. The date of manufacture is clearly marked on the upper of the boot as detailed overleaf.

MAINTENANCE

Boots should be visually inspected before being worn, check for cuts and abrasions to the boot. If wear has occurred the boots should

be replaced immediately with new tested/certied Dielectric boots.

If the yellow moulding of the boot can be observed coming through the blue rubber sole, with the exception of the 6mm hole in

the centre of the heel, this indicates the rubber sole is worn out and the Dielectric boots should be replaced immediately.

After 1 year’s wear the boots should be returned to Respirex International Ltd for re-testing. Respirex International Ltd is a

ISO9001/2000 registered Company and has a UKAS accredited laboratory. Please contact your local distributor for details.

Dielectric boots should be replaced by tested and certied electrically insulating footwear. The compounds and processes used

in the manufacture of the boots are specialised. Under no circumstances should uncertied footwear be used for live working

or situations where the wearer has the risk of being exposed to live electric currents or electric elds.