RT-1000 Antenna

RHOTHETA Page 10 of 17 User Manual

8 Now the mast can be installed on the flat ground. All screws have to be tightened.

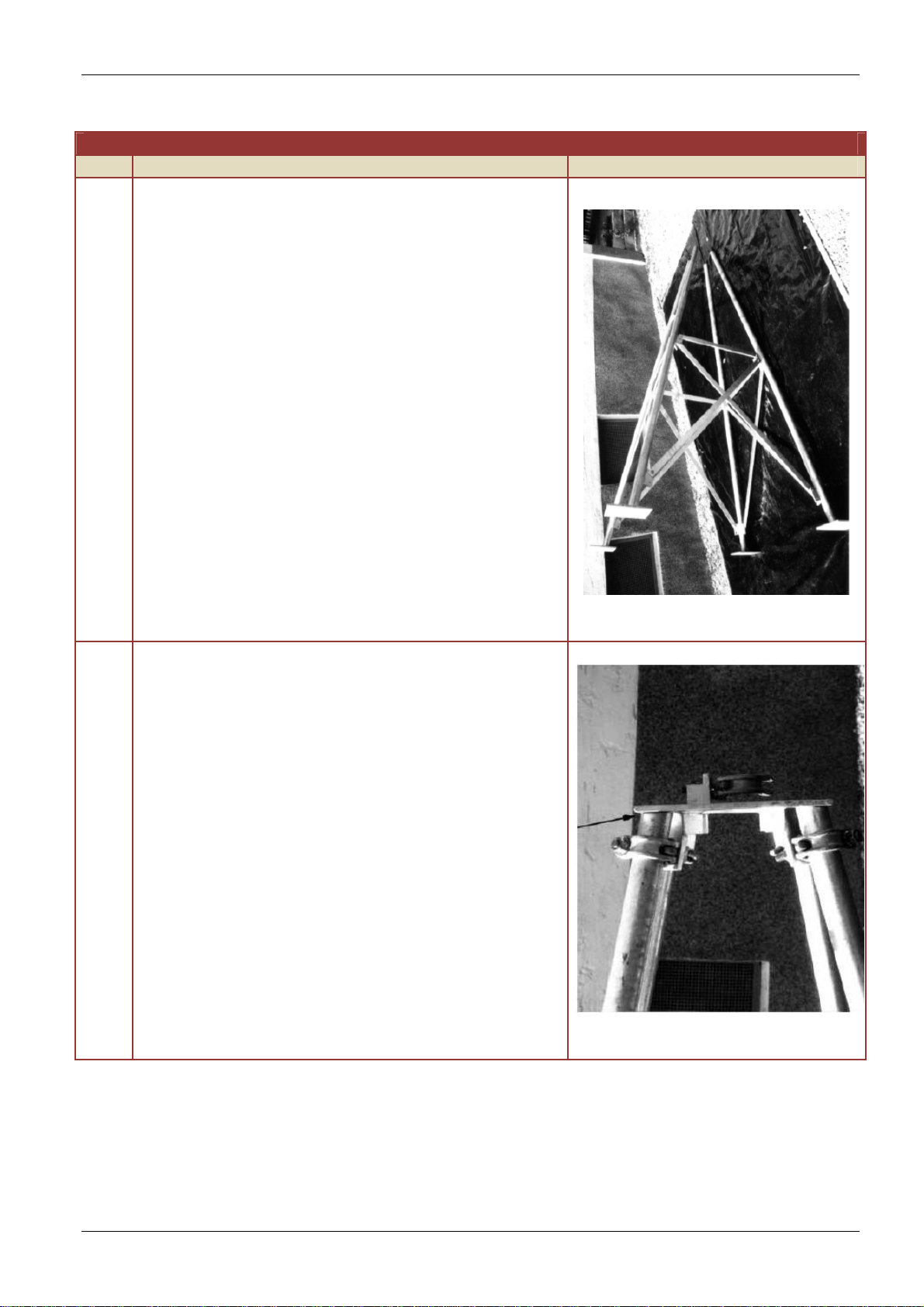

9 The eight suspension braces for the mast foot

plate needs to be installed now on the fish plates,

which have remained free (Figure 7).

Figure 7

10

You now screw the preassembled mast foot plate

(see drawing "mast") to the suspension braces.

You need to make sure that the hole for the lever

of the angular adjustment turns away from the

mounting of the installation box (Figure 7).

11 Open the loose clamps for the mast foot and assemble the mast. The cut at the mast

foot has to face towards the installation box. The mast needs to be loosely attached in

the gripper clamp, and then screw the clamp.

12

The installation box needs to be put between the provided fixation clamps. It should be

cantered and parallel to the mast tube and should have a distance of 60 mm to it. After

that, you have to mark the holes through the holes of the fixing clamps on the

installation box.

13 With the installation box removed out of the mast, drill the previously marked holes

with a 10 mm drill bit.

14

You have to create a breakthrough in the flange of the installation box to carry out the

data and power supply underground cable. We recommend to route the cable from the

exit site in the ground to the installation box through a galvanized steel pipe (42, 4 x

3,5mm). The steel pipe should be interred 30 cm under the ground and on the other

side you have to affix it with the aid of the rubber joint to the flange plate (see drawing

“mast base”). An appropriate rubber joint is included. The point, on which the cable

should be routed through the flange plate, is already marked on the flange plate.

15

You now have to mount the installation box with the supplied screws M8 x 30. The

screws, which connect the control cabinet to the holding brace, have to be bolted with

lock washers (on the side of the control cabinet). To assure a good ground connection

to the switchbox and the mast, the contact surface of the screws has to be cleaned

from paint. Before final tightening of the screws, they have to be sealed with UV-

resistant silicone (such as roofer usually use). Any inaccuracies can be compensated

by bending the fixation clamps or by shimming of the corresponding washer.