Ricoh A250 User manual

Other Ricoh Copier manuals

Ricoh

Ricoh FW 810 User manual

Ricoh

Ricoh Aficio MP 1350 User manual

Ricoh

Ricoh Aficio SP 5200S User manual

Ricoh

Ricoh FT7060 Quick start guide

Ricoh

Ricoh A229 User manual

Ricoh

Ricoh FW740 User manual

Ricoh

Ricoh MP CW2201sp User manual

Ricoh

Ricoh G-P3 User manual

Ricoh

Ricoh A217 User manual

Ricoh

Ricoh Aficio FT4027 User manual

Ricoh

Ricoh Aficio 1075 User manual

Ricoh

Ricoh D127 Quick start guide

Ricoh

Ricoh FT 4015 User manual

Ricoh

Ricoh B003 User manual

Ricoh

Ricoh Pro C720s User manual

Ricoh

Ricoh B125 User manual

Ricoh

Ricoh FT3020 Quick start guide

Ricoh

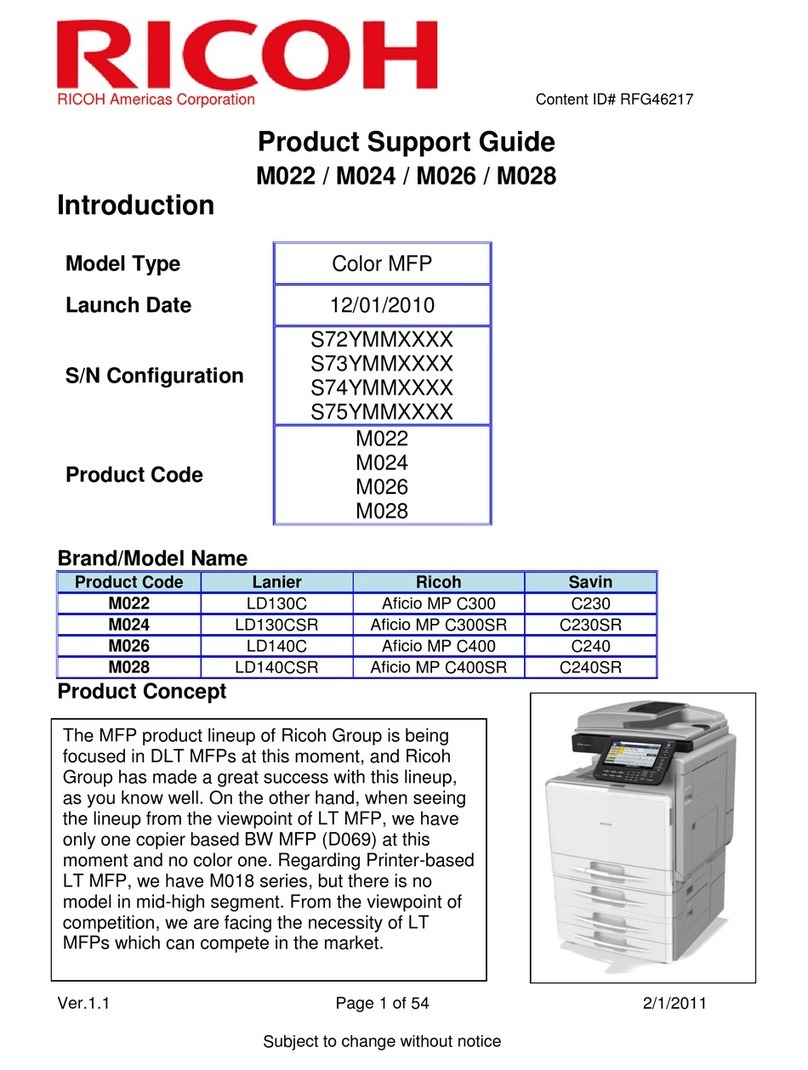

Ricoh M022 Installation instructions

Ricoh

Ricoh Pro C550EX User manual

Ricoh

Ricoh FT4220 Installation guide