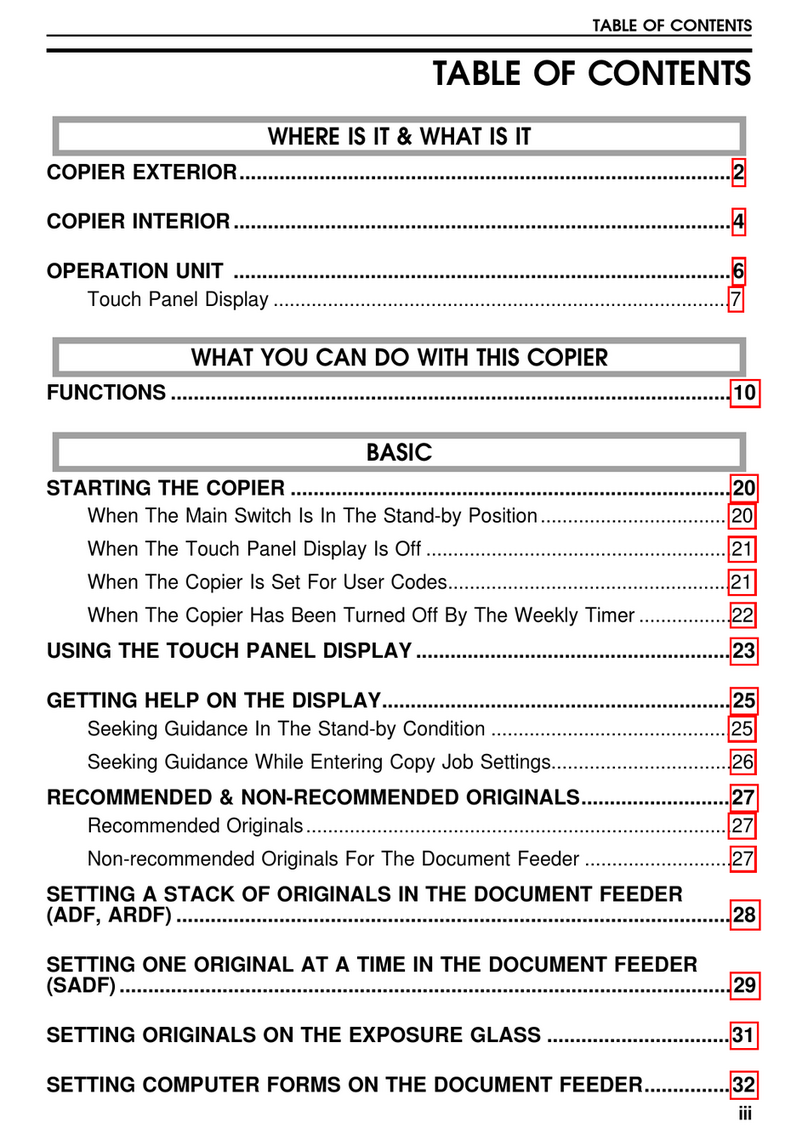

1.4 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

Motors

M1 Main Drives the diagonal transport unit, horizontal

transport unit, and distribution unit through

timing belts. 22

M2 Staple Unit

Positioning Drives the staple unit up or down to the

appropriate bin. (dc stepper) 5

M3 Jogger Unit

Positioning Drives the jogger unit up or down to the

appropriate bin. (dc stepper) 9

M4 Side bar Drives the side bar side to side according to

the paper size. (dc stepper) 1

M5 Grip Drives the gripper forward into the bin to grip

the copies and bring them to the stapling

position. (dc brush) 12

M6 Staple Feeds the staples and drives the stapler

hammer. (dc brush) 15

M7 Jogger Drives the jogger arm to align the copy. (dc

stepper) 18

M8 By-pass Tray Gate Drives the by-pass tray gate up or down to

switch the paper delivery tray. 36

Switches

SW1 Front Door De-energize the main motor and cuts 24 V

line when the front door is open. 8

SW2 Vertical Transport

Door De-energize the main motor when the vertical

transport door is open. 6

SW3 Horizontal

Transport Door Informs the main board if the cover is open. 20

Circuit Boards

PCB1 Main Controls overall sorter stapler functions. 31

PCB2 DC Power Supply Convert ac voltage to 5 V dc and 24 V dc to

supply power to all dc components. 26

PCB3 Bin Solenoid

Control 1 Interfaces between the bin solenoids 1 ~ 10

and the main board. 28

PCB4 Bin Solenoid

Control 2 Interfaces between the bin solenoids 11 ~ 20

and the main board. 30

Solenoids

SOL1~20 Bin Opens and closes the bin gate to direct the

copies into the appropriate bin. 27

SOL21 Grip Opens and closes the bin gate to drive the

grippers to grip copies on the bins. 14

SOL22 Pressure Release Releases pressure of the brake roller when

the paper is fed lengthwise. 38

Sorter Stapler

OVERALL MACHINE INFORMATION 6 March 1992

5