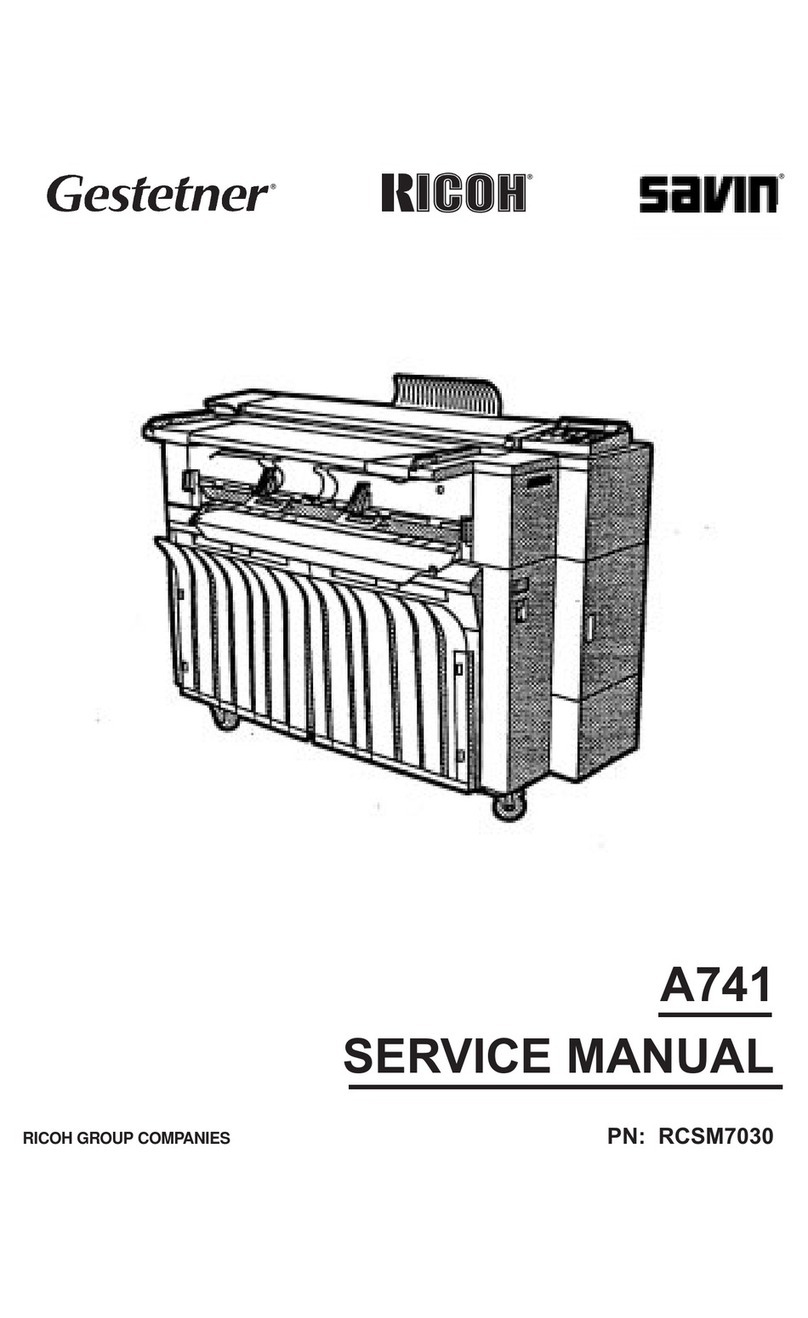

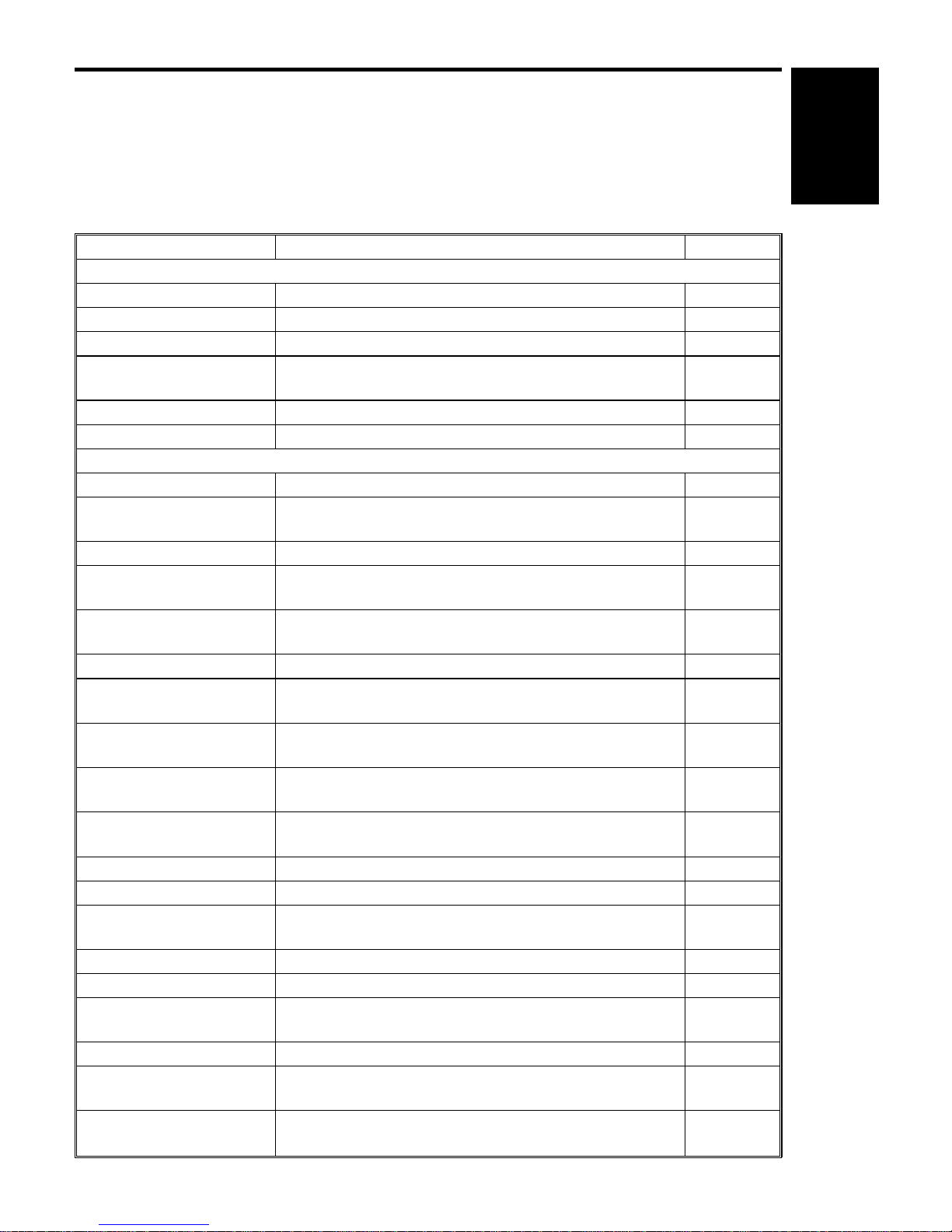

4. ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout on the reverse side of the Point to

Point (Water proof paper) index numbers.

4.2 RDH

Name Function Index No.

Motors

Feed Drives the feed and transport rollers. 3

Belt Drive Drives the transport belt. 7

Inverter Drives the inverter and exit rollers. 34

Blower Supplies air to the air knife and draws air from the

vacuum section. 5

Separator Drives the original separator. 21

Sensors

Original Set Detects if the original is set on the document handler. 31

Entrance Detects the original leading edge and de-energizes

the feed belt drive clutch. 33

1st Transport Detects jams in the transport section. 16

2nd Transport Detects the original leading edge and lowers the

original feed motor speed. 15

Registration Detects the original trailing edge for the original stop

position calculation. 12

Inverter Entrance Detects jams in the transport belt section. 24

1st Inverter Detects the original trailing edge and reverses the

inverter drive motor rotation. 29

2nd Inverter Detects the original leading edge and energizes exit

roller release solenoid. 30

Exit Detects the original leading edge and lowers the

inverter drive motor speed. 32

Single Feed Set Detects the leading edge of the original in the single

feed table and turns the original feed motor. 13

Single Feed Exit Detects jams in single feed mode. 25

Lift Detects if the RDH is open. 2

CFF Detects if the computer form is set in the CFF guide.

Counts the holes lined up to the computer form. 9

Original Length Detects if the original stopper is set for 81/2" position. 19

Original Height Detects the original height on the RDH. 20

Separator H.P. Detects if the original separator is in the home

position. 22

Separator Detects if the last original of the original stack is fed. 23

Inverter Unit Cover

(Switch) Detect if the inverter unit cover is opened. 27

Original Width

(Potentiometer) Detects the original width in the stack feed mode. 17