Technical Bulletin PAGE: 1/1

Model: SP3 Date: 31-Oct-97 No: 4

Subject: Controller Board ROM Modification Prepared by: A.Tokoyama

From: QAC Field Information Dept.

Classification: Troubleshooting

Mechanical

Paper path

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

Other ( )

This bulletin describes the software modifications for the printer controller board.

The new software version has been included in the controller board from October

production.

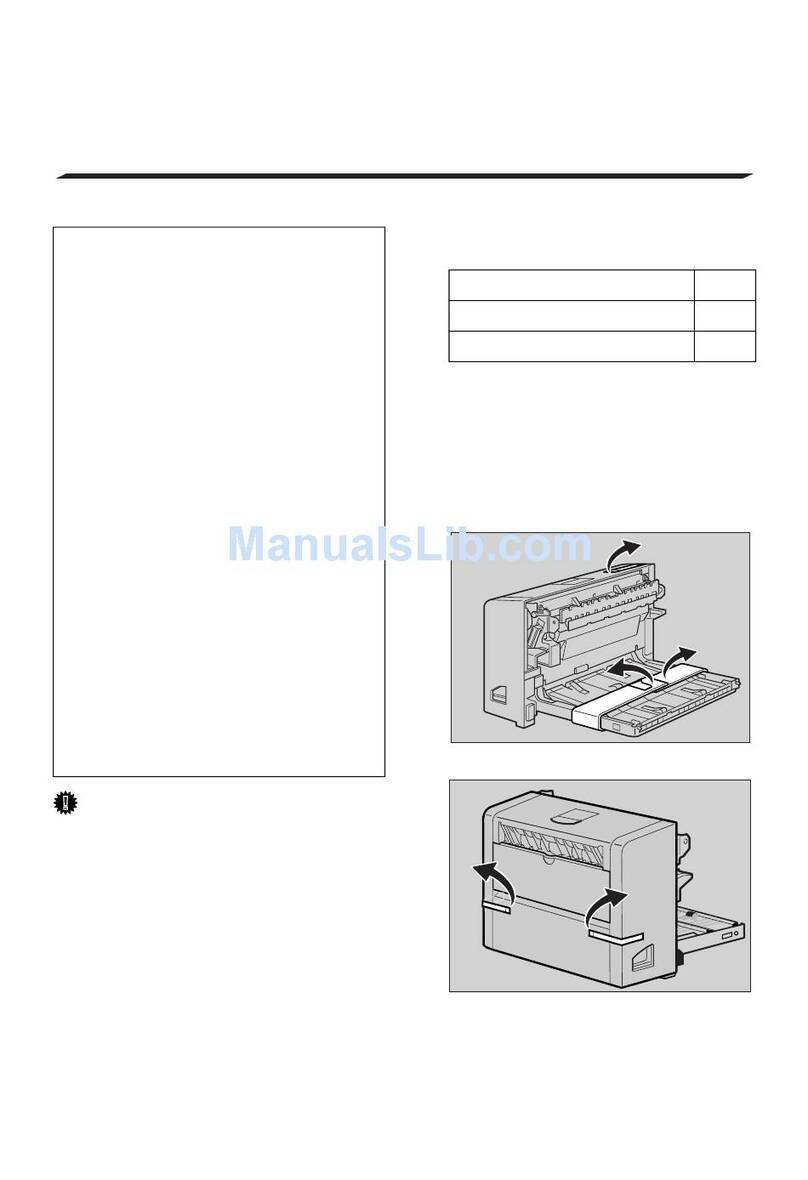

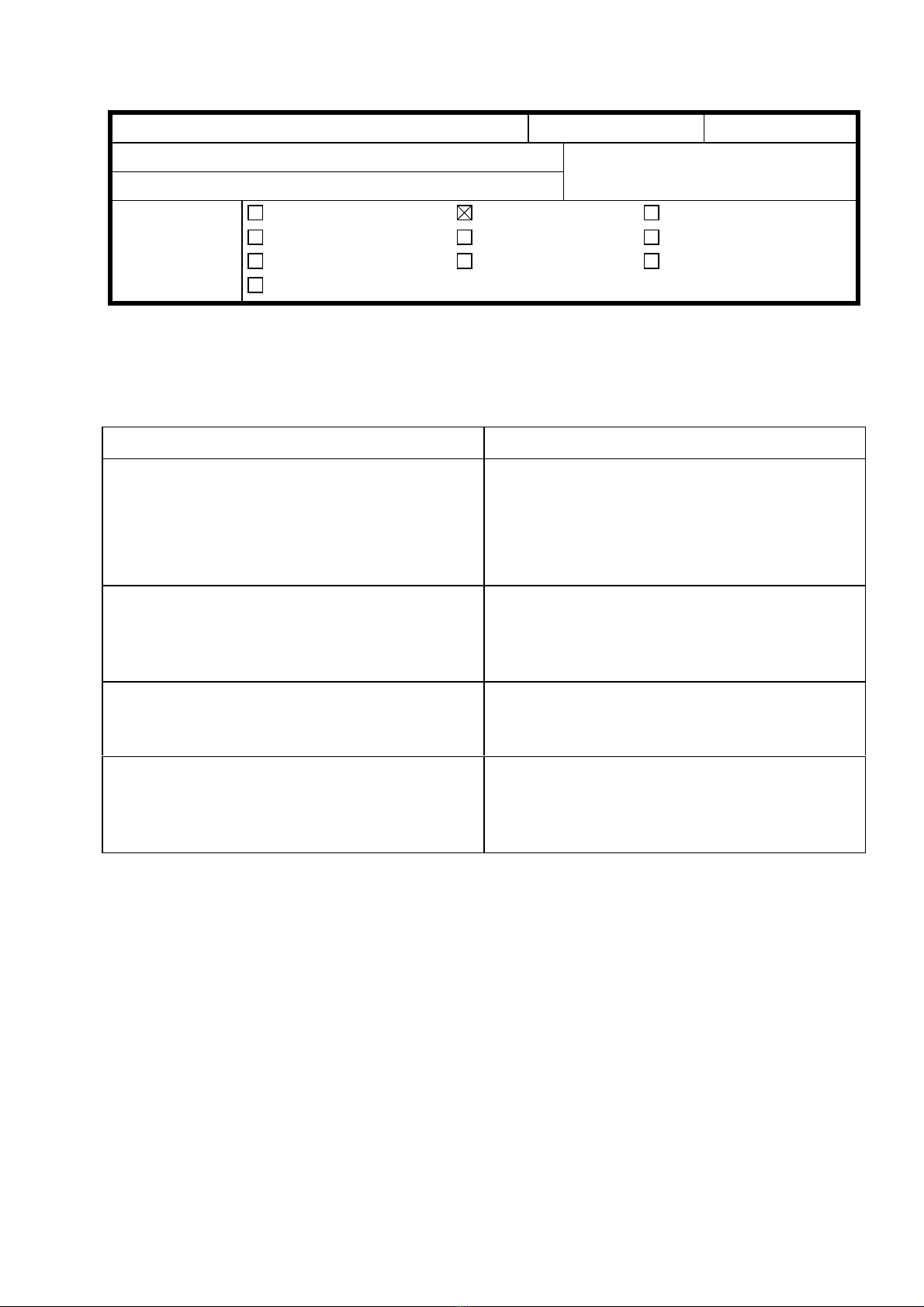

Category Problem Countermeasure

Scanner Option When there is an original in the ADF and no

paper on the exposure glass, if the user scans

the original using the flat-bed original mode

from the PC, the controller may hang up.

Modified software

Scanner Option Whenever the power is on, the controller board

sometimes performs a SCSI Bus reset. Modified software

Scanner Option When scanning using 256 gray scales, 300dpi,

and the maximum scanning area, the controller

cannot scan the image and a time out error

occurs.

Modified software

New PCL

Printer Driver

(Software 2000)

Using the new PCL printer driver (by Software

2000), if a different paper tray is selected for

the first page with this printer driver, the first

page cannot be stapled together with the

following pages

Modified software

Important: This modification is required if the scanner option is installed.

Before the scanner option is installed, check the software version of the

controller board.

If it is ver. 2.29 or earlier, replace the controller software.

NOTE: Note that the software version used on the production line skipped from ver. 2.27

to 2.30.

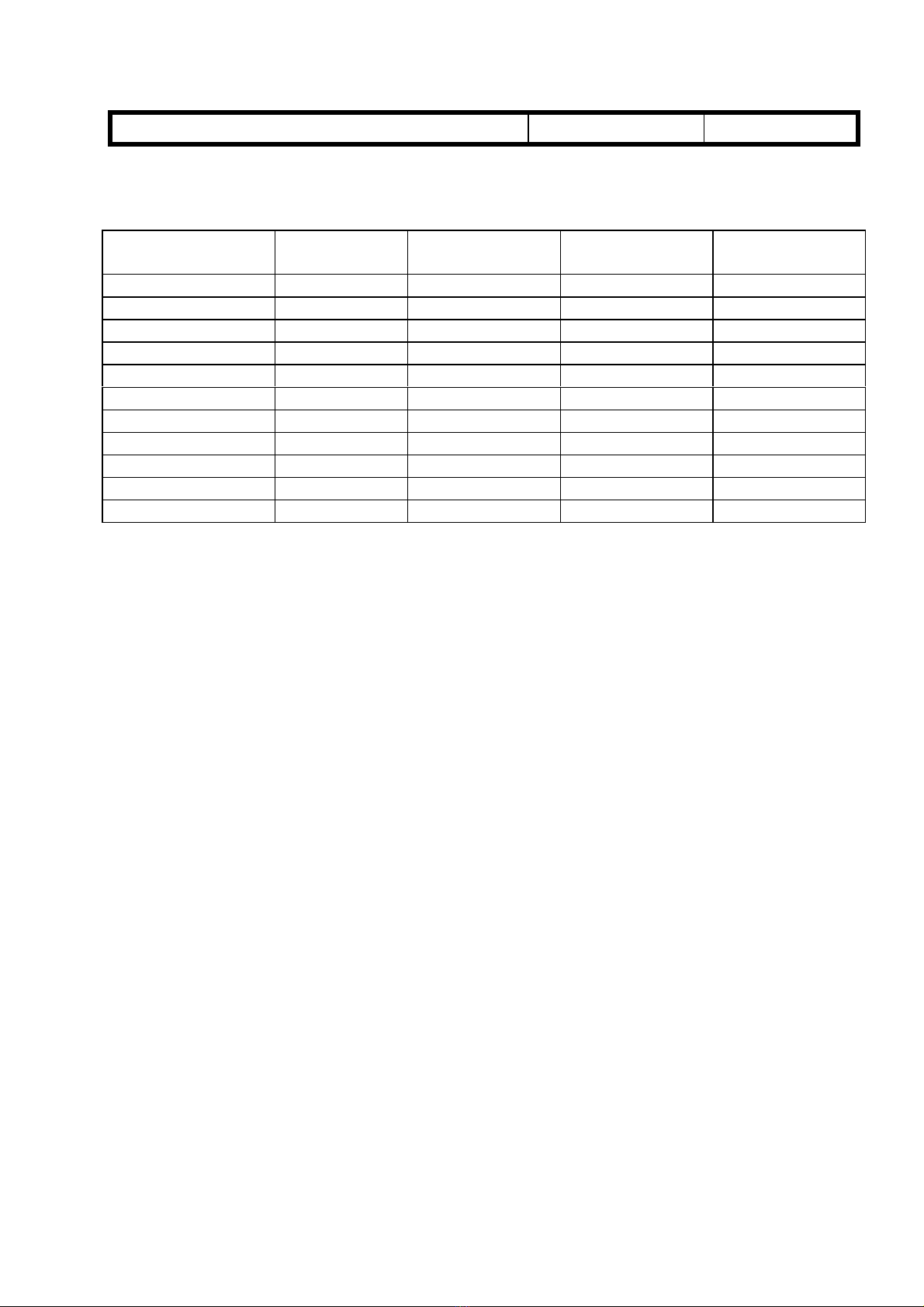

Controller Board Part Number and Software Version:

Product Code Controller Board Software Version

A649-00 A6495100Q ver. 2.30