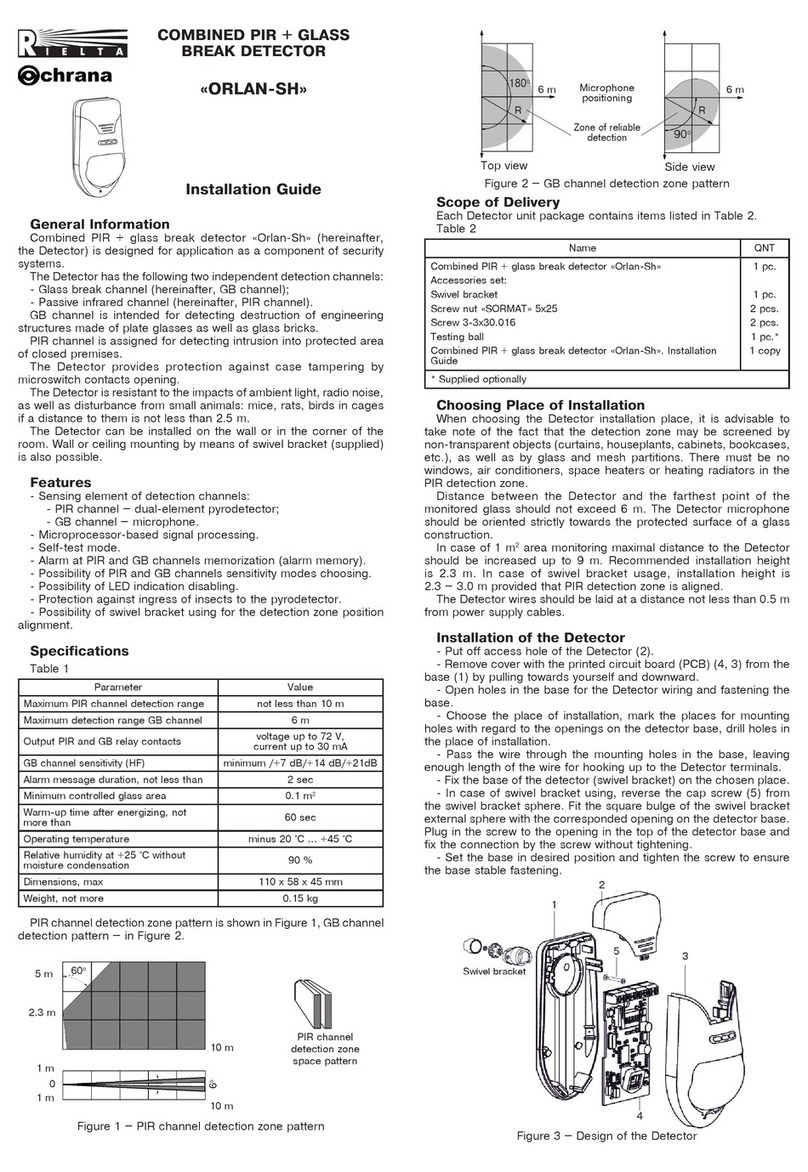

Note –If the Detector does not identify movement within the detection

zone, it is necessary to change Detector position by means of swivel bracket

(in case of wall mounting the horizontal turning angle of the Detector on swivel

bracket – ± 450, vertical – not less than 200).

Under absence of movement inside the detection zone, LED indicator should

not light.

Upon the expiry of 5 min of either of the two testing modes, the Detector

automatically changes to normal mode of operation (if DIP-switch «3» is in ON

position, alarm message generation is displayed by LED indicator lighting red).

The detection zone position in space can be appraised visually by changing

camera to continuous mode of operation and monitoring movements by video

display unit.

LED Indicator Disabling

For the Detector operation masking, the mode of LED indicator disabling is

provided. DIP-switch «3» is in OFF position. In this mode LED is operable only

during first minute after energizing or during failure message generation.

Self-Test Mode

The Detector provides self-testing of the following parameters: amplifier

operability, input voltage, ambient temperature.

In case of self-test failure (amplifier failure, voltage drop lower than 10.0 V,

ambient temperature out of permissible temperature range), «Failure» message

is generated by opening the relay output contacts repeated by periodical LED

indicator blinking green at 1 Hz frequency, the camera is switched OFF.

«Failure» message duration – 15 min. After elimination of malfunction, the

Detector returns to switching and self-test mode.

ATTENTION! The Detector must be checked at least once annually for

functional testing.

ATTENTION! In the secured zone there must be warning about CCTV

monitoring of the object area.

Storage and Transportation

The Detectors in their original packing may be shipped by any transport

means in covered vehicles (in railway, cars, trucks, sealed heated compartments

of aircraft, ship cargo holds, etc). The storage room should be free from

current-conducting dust, acid vapors, alkali and gases that cause corrosion and

destroy insulation

The Detectors in their original packing may be stored not more than 3 months.

During this period the Detector package should not have bloodshot spots and

impurities.

Upon the expiry of 3 months, the Detector should be released from the package.

Manufacturer’s Guarantees

The Manufacturer guarantees conformity of the Detector to it’s Technical

Specifications if conditions of transportation, storage, assembling and operation

are observed. The guaranteed storage period is 27 months since the date of

manufacturing the Detector.

The guaranteed period of operation is 24 months since the date of

commissioning within the storage period guaranteed.

The Detectors that are found to non-conforming to it’s Technical Requirements

shall be repaired by the Manufacturer, provided the installation and operation

rules have been complied with.

Acceptance and Packing Certificate

Passive infrared detector «Foton-17»,

serial number ____________,

has been manufactured in compliance with the active technical documentation

and classified as fit for operation and packed by «RIELTA» JSC.

Person in charge of acceptance and packing

QC representative_________________ __________________.

day, year, month

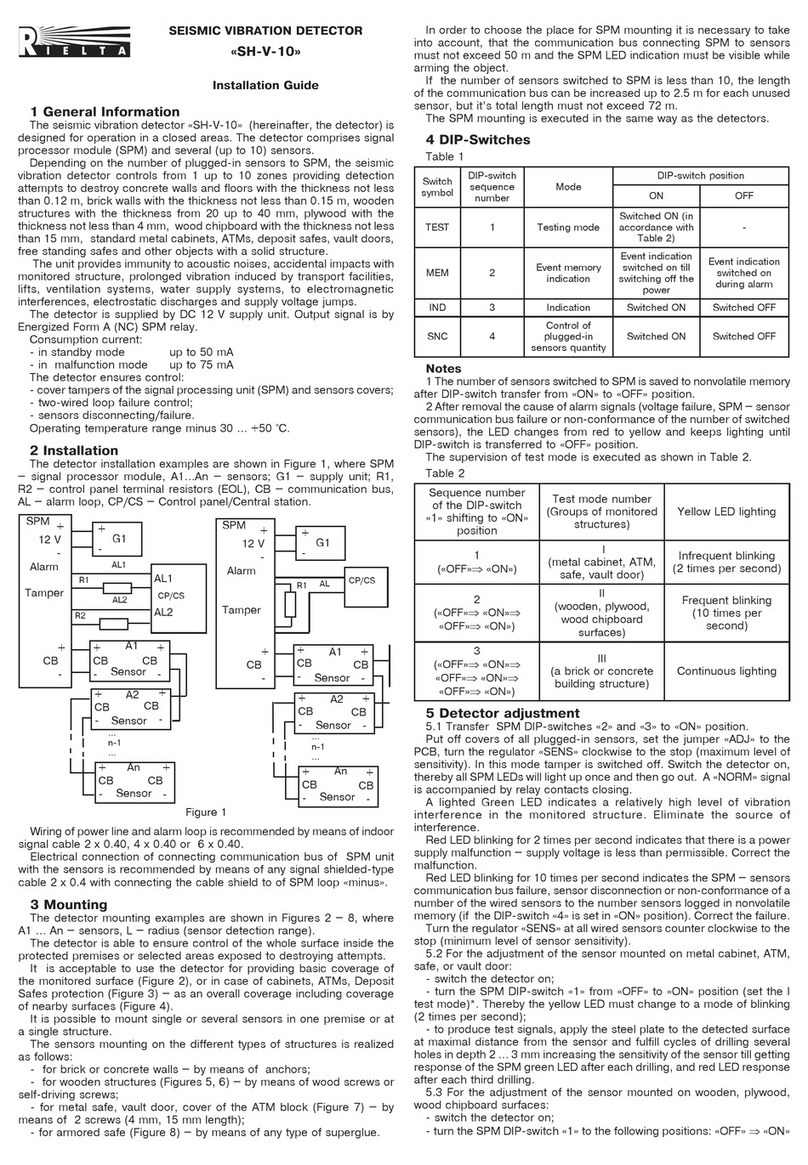

Table 3 – DIP-switches Setting

Mode DIP-switch

DIP-Switches Position

ON OFF

Sensitivity «1» Normal High

Testing «2» Sensitivity

adjustment

Detection zone

alignment

Indicator «3» ON OFF

Alarm message duration Alarm message duration is set by DIP-switches «4» & «5»

position. See Table 4

Table 4

DIP-switches

Alarm message duration

«4» «5»

OFF OFF Continuously

ON OFF 10 sec

OFF ON 30 sec

ON ON 120 sec

LED Indication

Two-color LED indicator located at the front cover displays the Detector mode.

Table 5 – The Detector state during message transmission.

Message LED Color LED State TV-camera State

«Warm-up Time» RED Periodical blinking at 1 Hz

frequency during 1 min Operation during 1 min

«Norm» - OFF OFF

«Alarm» RED ON ON

«Failure» GREEN Periodical blinking at 1Hz

frequency during 15 min OFF

«Temperature

problem» GREEN

Periodical blinking at 1 Hz

frequency during thermal

excursion period

Operation

10 sec during an alarm

message generation

«TV monitoring» GREEN

Periodical blinking at

0.5 Hz frequency during

TV-camera operation

Continuous operation

Functional Check

After energizing of the Detector, self-testing process is realized during one

minute. It ensures control of the following parameters: input voltage, ambient

temperature, operation capacity of the amplifier channel. During the procedure,

the LED indicator is blinking red (irrespective of the DIP-switch «3» position), relay

contacts are opened, TV-camera is in operation.

Testing Mode

Upon the expiry of the warm-up time, the Detector is ready for operation.

Checking procedure provides two testing modes, lasting 5 min.

1) Detection zone position location

DIP-switches position: «2» – OFF, «3» – ON. This mode is intended for each

beam of detection zone positioning in the secured premises. Under the condition

of each beam crossing the LED indicator switches for 0.25 sec. Optimal speed

of movement at maximal distance – 0.5 m/sec.

2) Sensitivity mode adjustment

DIP-switches position: «2» – ON, «3» – ON. This mode is intended for Detector

sensitivity appraising (the distance, which is possible to pass through the detection

zone up to the point, where the movement is detected, and alarm message

is generated). The LED indicator blinks for 0.25 period under the condition of

detection zone beam crossing, and for 5 sec during alarm message generation.

High sensitivity level – DIP-switch «1» is in OFF position. It is the basic

operation mode. «Alarm» message is generated after 2 – 4 steps within the

detection zone (after single LED indicator switching ON for 0.25 sec period).

Normal sensitivity level – DIP-switch «1» is in ON position. This mode is

recommended for the rooms with severe interference conditions. «Alarm» message

is generated after 4 – 5 steps within the detection zone (after two-shot LED

indicator switching ON for 0.25 sec period).

Stop after each alarm message generation, wait until the LED indicator is

disabled for and 8 – 10 sec, then continue movement through the detection zone.

Rev.1 of 20.02.2014

№00044

Made in Russia

«RIELTA» JSC, www.rielta.com,

Tel./fax. +7 (812) 233-0302, 703-1360,