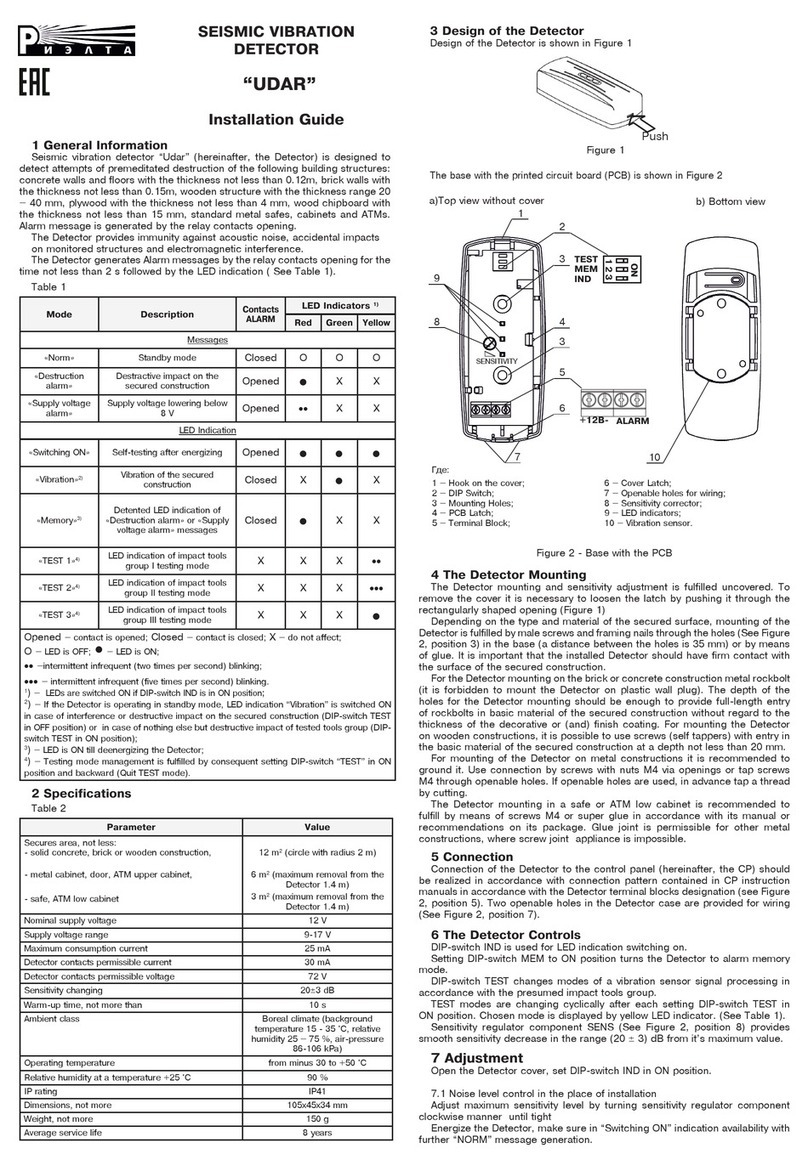

1 General Information

1.1 Security wireless inertia detector «GRAN-RK» (hereinafter «the Detector»)

is designed to detect changing of the monitored item position from it’s its

initial installation place and sending an alarm messages via wireless two-way

communication within frequency range from 433,05 to 434,79 MHz by the

«RIELTA Contact-R» protocol.

1.2 The Detector is designed for operation as a component of a system, that

is operated by a control panel (hereinafter «CP») supporting «RIELTA Contact-R»

wireless two-way communication protocol.

1.3 The Detector generates no interferences to other types of detectors, as

well as to domestic radio equipment.

1.4 The detector is powered by two power-supply batteries СR2450 type: main

and back-up one, both inside the Detector case.

1.5 The Detector generates and transfers messages with the following

information content:

- «Normal» – under keeping initial position;

- «Tilt-Alarm» – under tilt changing for 3° or more;

- «Displacement-Alarm»– item displacement from its initial position at a distance

0.25 m or more with the acceleration of 0.5 m/s

2

and more along any axis during

the period at least 1 s;

- «Tamper» – under case tampering or the detector removal from its place

of installation;

- «Failure» – under long-term vibration interferences;

- «Main power-supply low-battery»

–

main power-supply battery voltage drop

for less than 2.4 V;

- «Backup power-supply low-battery»– back-up power-supply battery voltage

drop for less than 2.4 V;

1.6 Wireless two-way communication «Detector – CP

»

, is provided at the main

or reserve frequencies. Switching between the main and reserve frequencies is

accomplished automatically.

1.7 The detector provides immunity to electromagnetic interferences.

1.8 Industrial interferences created by the Detector does not exceed the

limits for the facilities used in housing, commercial zones or production areas

with low power consumption.

1.9 The Detector is designed for continuous and uninterrupted operation.

1.10 The Detector operational stability provides its normal operation under

the following influencing factors:

a) Tilt changing for at least 1°,

b) Displacement from its initial position for the distance not more than 0.1 m

with the acceleration of 0.2 m/s2and more along any axis during the period

at least 1 s.

1.11 The Detector provides a possibility of a tilt sensitivity adjustment (the

sensitivity value is adjusted as one of a number of: 3°, 10°, 25°, 45°), as well as

displacement threshold adjustment (displacement threshold is adjusted as one

of a number of: 1 – min, 2, 3, 4, 5, 6, 7, 8 – max).

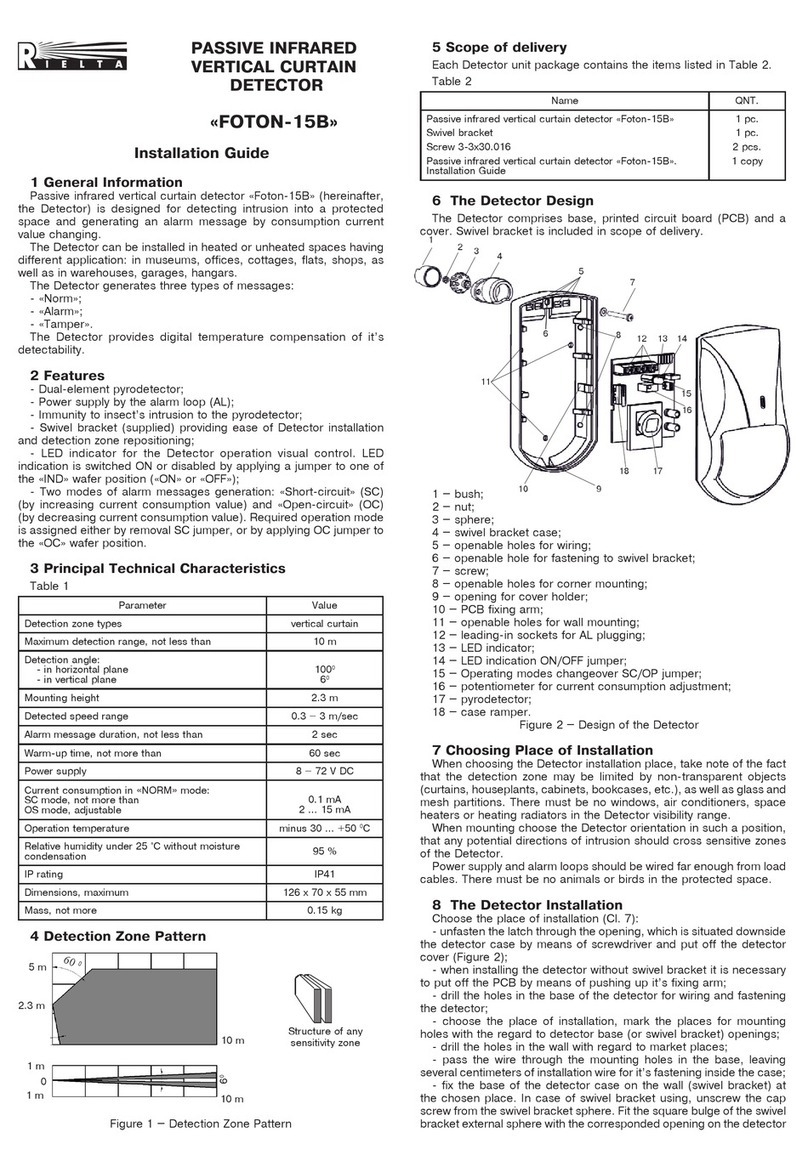

2 Specifications

Table 1

Parameter Name Value

Power supply 2,6 V … 3,8 V DC

Operating temperature

minus 10 … +50 °С

Permissible relative humidity at +35 °С without moisture

condensation 95 %

Dimensions, max 65х55х20 mm

Weight, max 0,05 kg

IP rating IP54

Mean time to failure, not less 60 000 hours

Average service life 8 years

Battery life, up to 12 months

3 Scope of Delivery

Each Detector unit package contains the items listed in Table 1.

Table 2

Description Quantity

Security wireless inertia detector «GRAN-RK» 1 pc.

Lithium power-supply battery СR2450 2 pc.

Screw 3-3х30.016 1 pc.

The Detector Installation Guide 1 copy

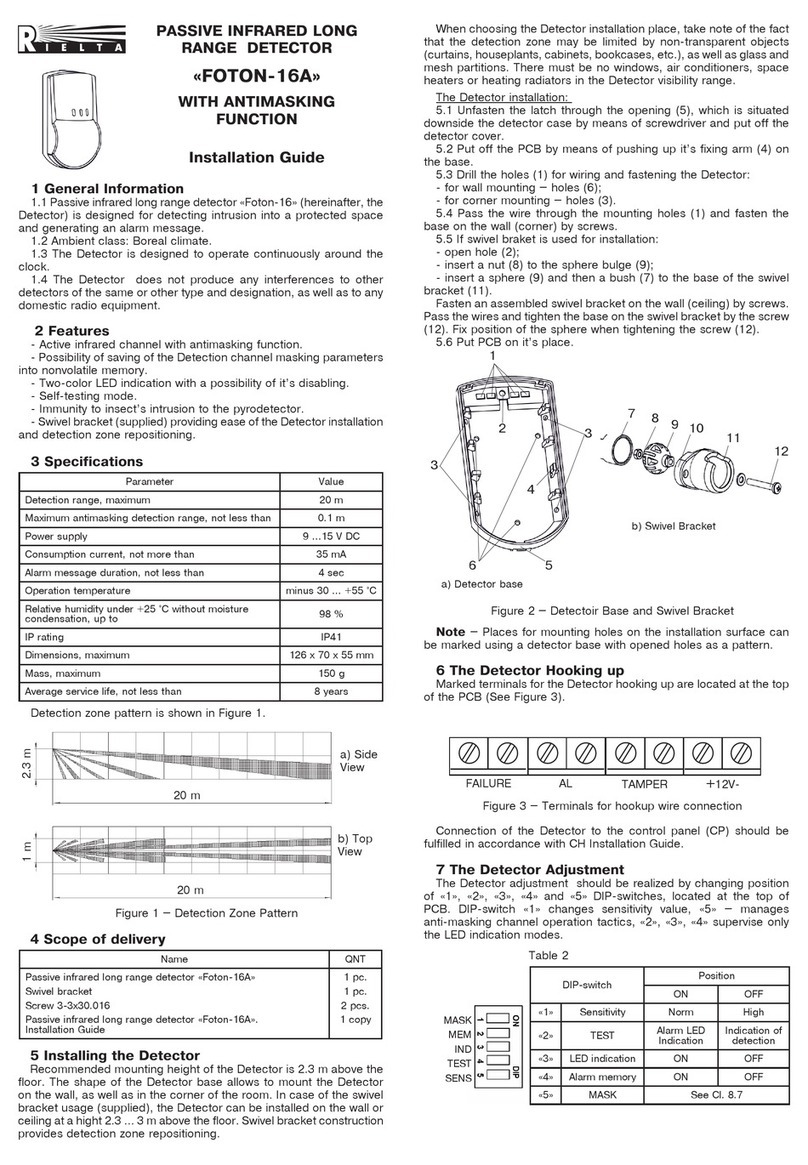

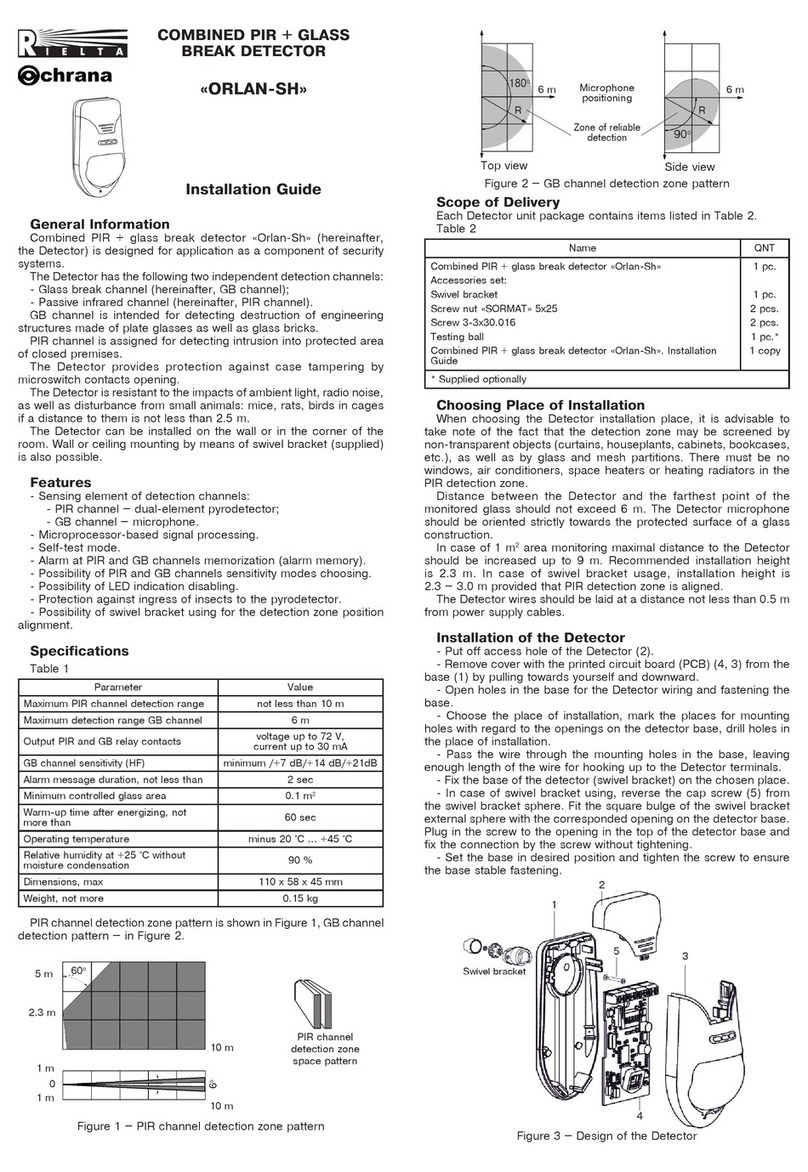

4 The Detector Design

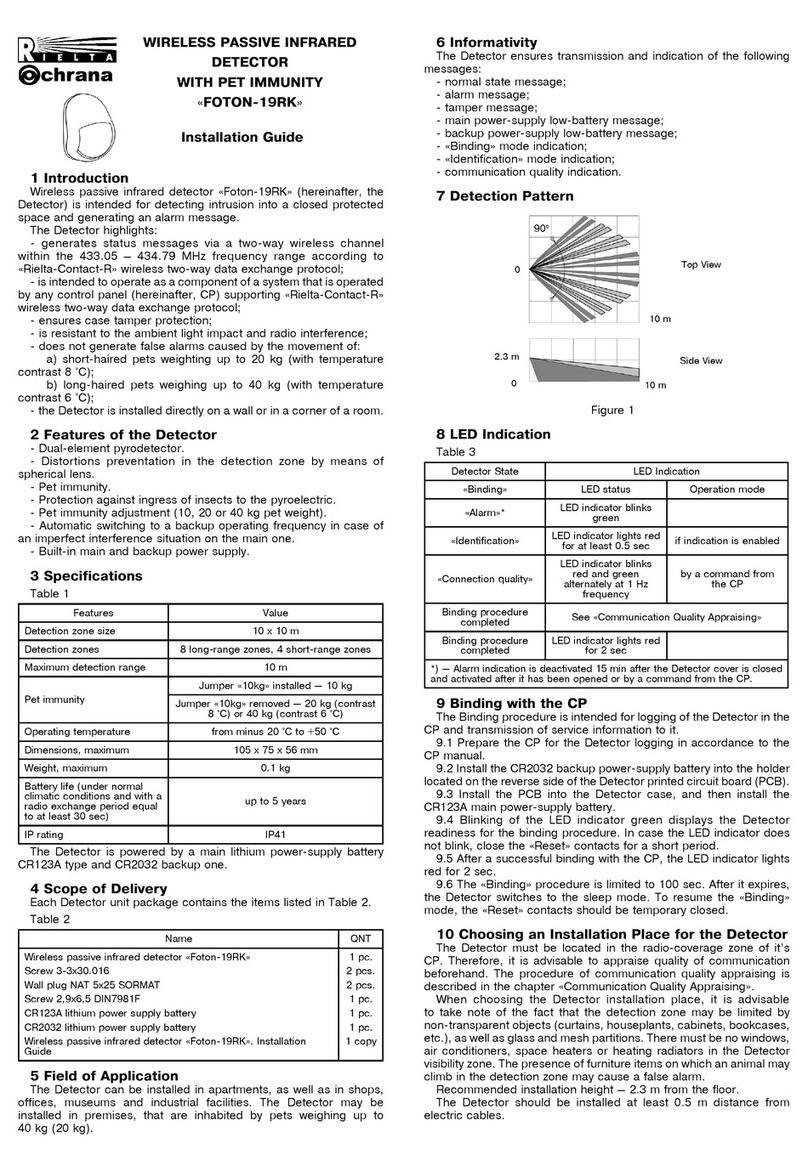

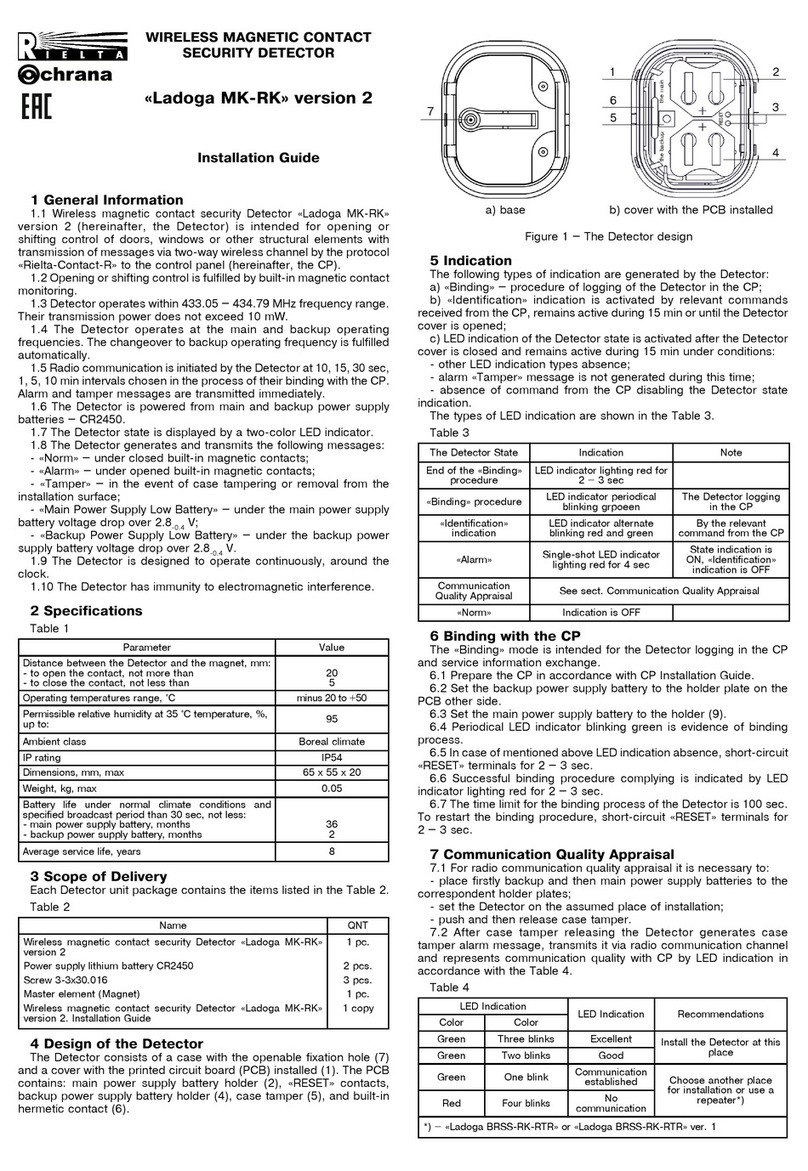

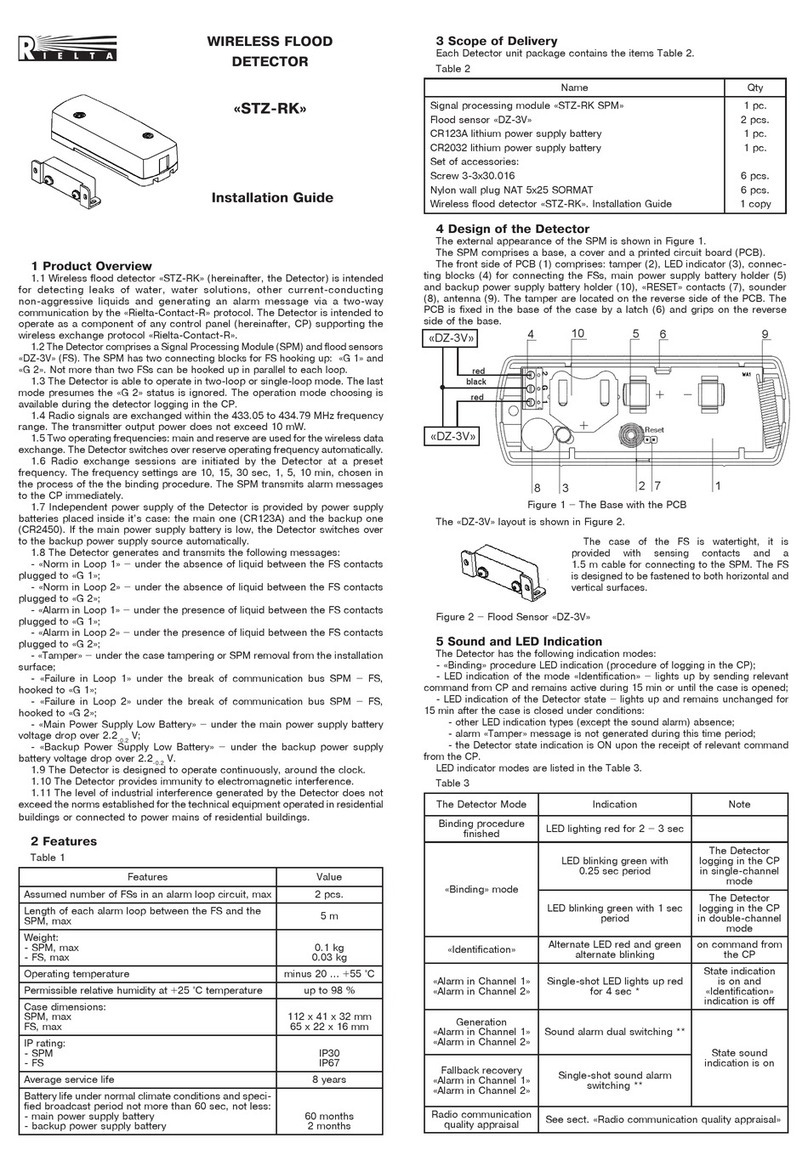

The Detector layout is shown in Fig.1.

SECURITY WIRELESS INERTIA

DETECTOR

«GRAN-RK»

Installation Guide

The Detector comprises the following elements: the base with an openable

fixing hole (6) and a case cover with the printed circuit board (PCB) installed (1).

Main power-supply battery holder (2), «Reset» contacts (3), backup power-

supply battery holder (4), tamper (5) are located on the PCB.

5 Led indication

The Detector generated the following LED indication types:

- LED indication of the mode

«

Binding» (procedure of the Detector logging

in the CP);

- LED indication of the mode

«

Identification» is switched ON by the relevant

command from the CP;

- the LED indication continues lighting during 15 minutes after the case is

closed if other types of indication are OFF, and «Tamper»message or indication

inhibition command from the CP are not generated.

The LED indication modes are listed in Table 3.

Table 3

The Detector Mode LED indication Note

Binding procedure finishing

LED lighting red for 2-3 s

«Identification» Alternate Red and green LED

lighting

«Identification» indication Alternate LED blinking red

and green

by the relevant command

from the CP

«Tilt-Alarm»*

«Displacement-Alarm»*

LED blinking red every 4 s

until the relevant messages

delivery is conformed

«State» indication is

ON, «Identification»

indication is OFF

«Communication Quality» See section «Communication Quality Appraising»

«Interference»* indication

LED blinking green with

the frequency 5 Hz under

detection of a movement with

acceleration of 0.2 m/s and

more

«State» indication is

ON, «Identification»

indication is OFF

Initial orientation storage

procedure finishing LED lighting green for 2-3 s

«State» indication is

ON, «Identification»

indication is OFF

«Norm» Indication is OFF

*) – The LED indication of the Detector

6 Binding with the CP

The binding procedure is intended for logging of the Detector in the CP with

further service information exchange.

6.1 Prepare CP for binding according to the CP Installation Guide.

6.2 After completing sect. 6.1, install the backup power-supply battery to the

backup power-supply battery holder (4) and then the main one to the holder (2).

6.3 Alternate LED blinking green indicates that the Detector is in

«

Binding»

mode.

6.4 In case of the absence of the indication mentioned above, close the

contacts «Reset» for 2-3 s.

6.5 Successful binding procedure finish is displayed by the Led indicator

lighting red for 2-3 s.

6.6 The time of binding procedure fulfillment is limited to 100 s, after it the

Detector switches to a sleeping mode. For «Binding» mode resumption it is

necessary to close the contacts «Reset» for 2-3 s.

7 Operating Modes

The Detector provides two operating modes – Mode 1 and Mode 2.

7.1 At Mode 1 the initial orientation in the space is stored after each «Tilt-

Alarm» and «Displacement-Alarm» message generation.

7.2 At Mode 2 the initial orientation in the space is stored after closing the

case of the Detector.

The «Norm» mode resumption after «Tilt-Alarm» message generation is fulfilled

only after the Detector initial position is restored.

7.3 The Detector operating mode is defined by the state of case tamper con-

tacts during initial 2 seconds after the successful binding procedure finishing

or during initial 2 seconds after energizing of the Detector logged in the CP. If

the tamper contact is closed, the Detector switches to Mode 1; if the tamper

contact is opened, the Detector switches to Mode 2.

7.4 To finish the Detector initial position storage procedure, it is necessary to

ensure its immobility for the time not less than 5 s. The successful finish of the

storage procedure is displayed by generation of «Norm» message and repeated

by the correspondent LED indication (See table 3).

8 Availability Check

8.1 To check the Detector availability it is necessary to:

- put the base on the flat surface;

- set the cover with the PCB on the base and leave it fixed for 8-10 s.

8.2 After getting the regular

«

Norm

»

message, the Detector should be displaced

for 25-30 cm or tilted for 3° or more. After detecting change of its initial position,

the Detector should transmit the message «Tilt-Alarm» or «Displacement-Alarm» and

repeat it by red LED indicator, located on the PCB (See Table 3).

9 Communication Quality Appraising

9.1 In order to check the wireless communication availability, accomplish the

following steps:

- set at first the back-up power-supply battery, than the main one to the holders;

- place the Detector to the assumed place of mounting;

- push and release The Detector tamper contact.

9.2 After tamper contact release, the Detector generates

«

Tamper

»

message and

transmits it via radio communication channel. The message is followed by the LED

indication, displaying the radio communication quality in accordance with Table 4.

а) Base b) Cover with the circuit board installed

1

6

2

3

4

5

BACKUP MAIN

RESET

Figure 1