- 2 -

Content

1 Notes on safety ................................................................................................................ 2

2 Function ........................................................................................................................... 3

2.1 Appropriate Use ......................................................................................................... 3

3 Marking of the coupling .................................................................................................... 4

4 Storage............................................................................................................................. 4

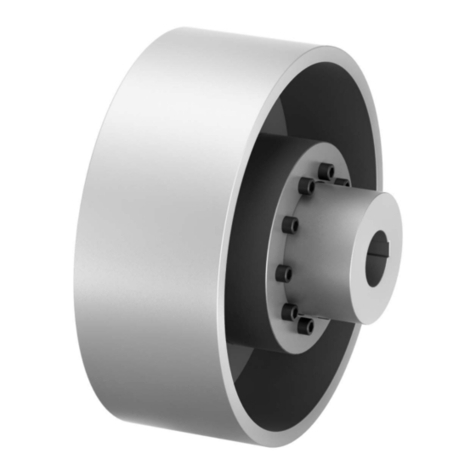

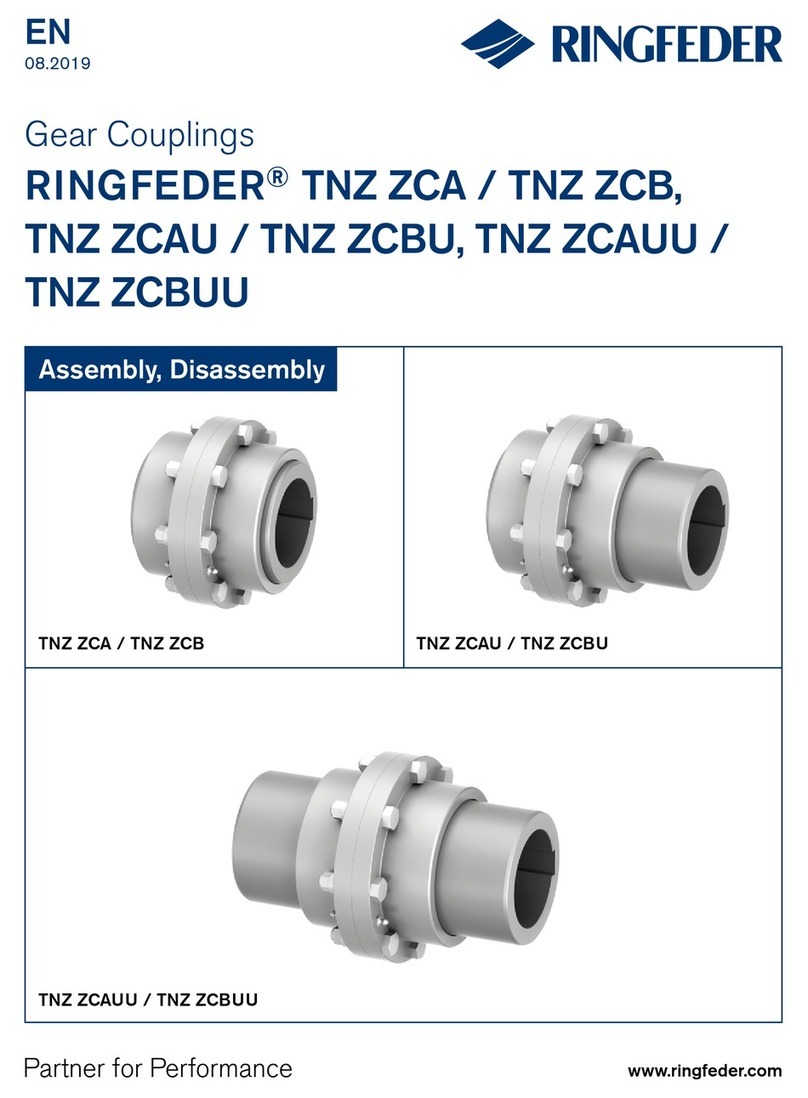

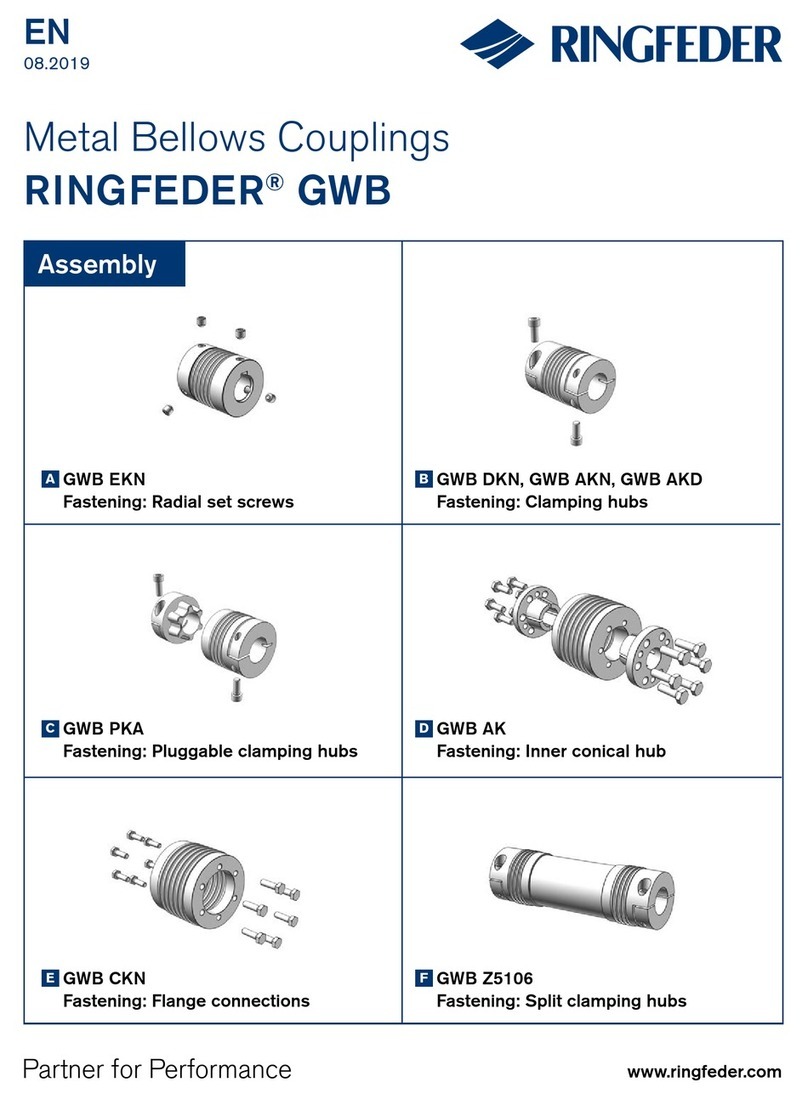

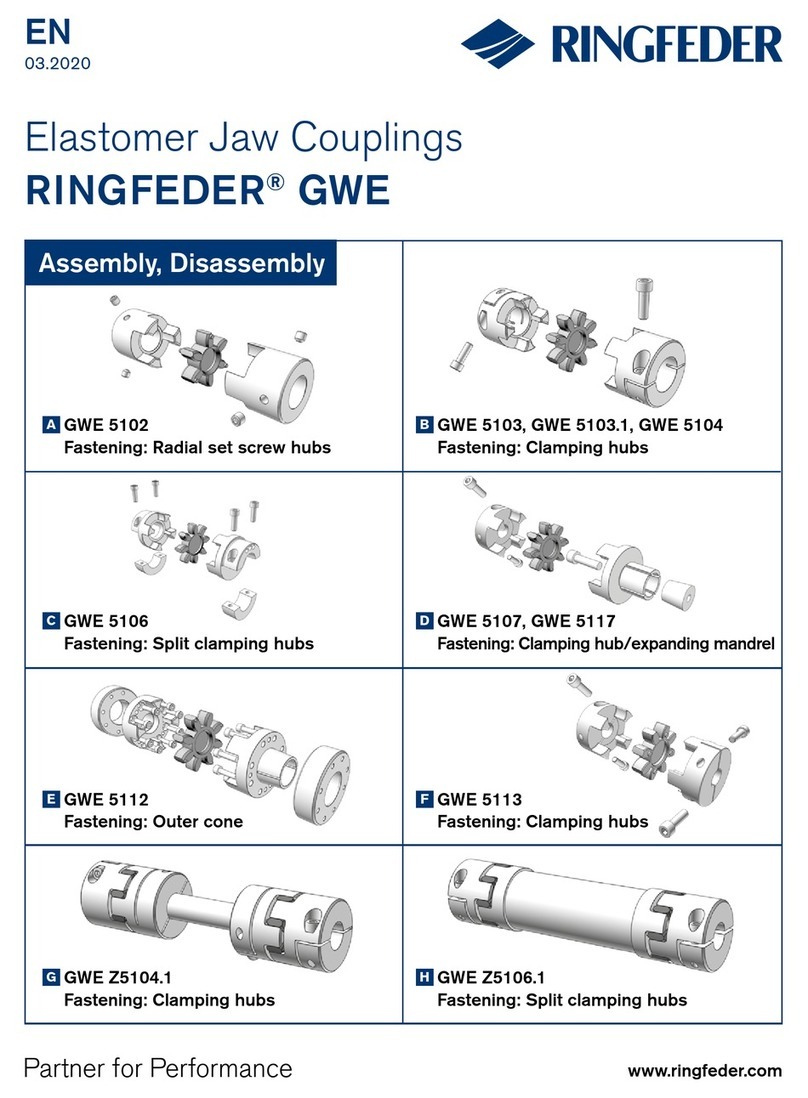

5 Construction ..................................................................................................................... 5

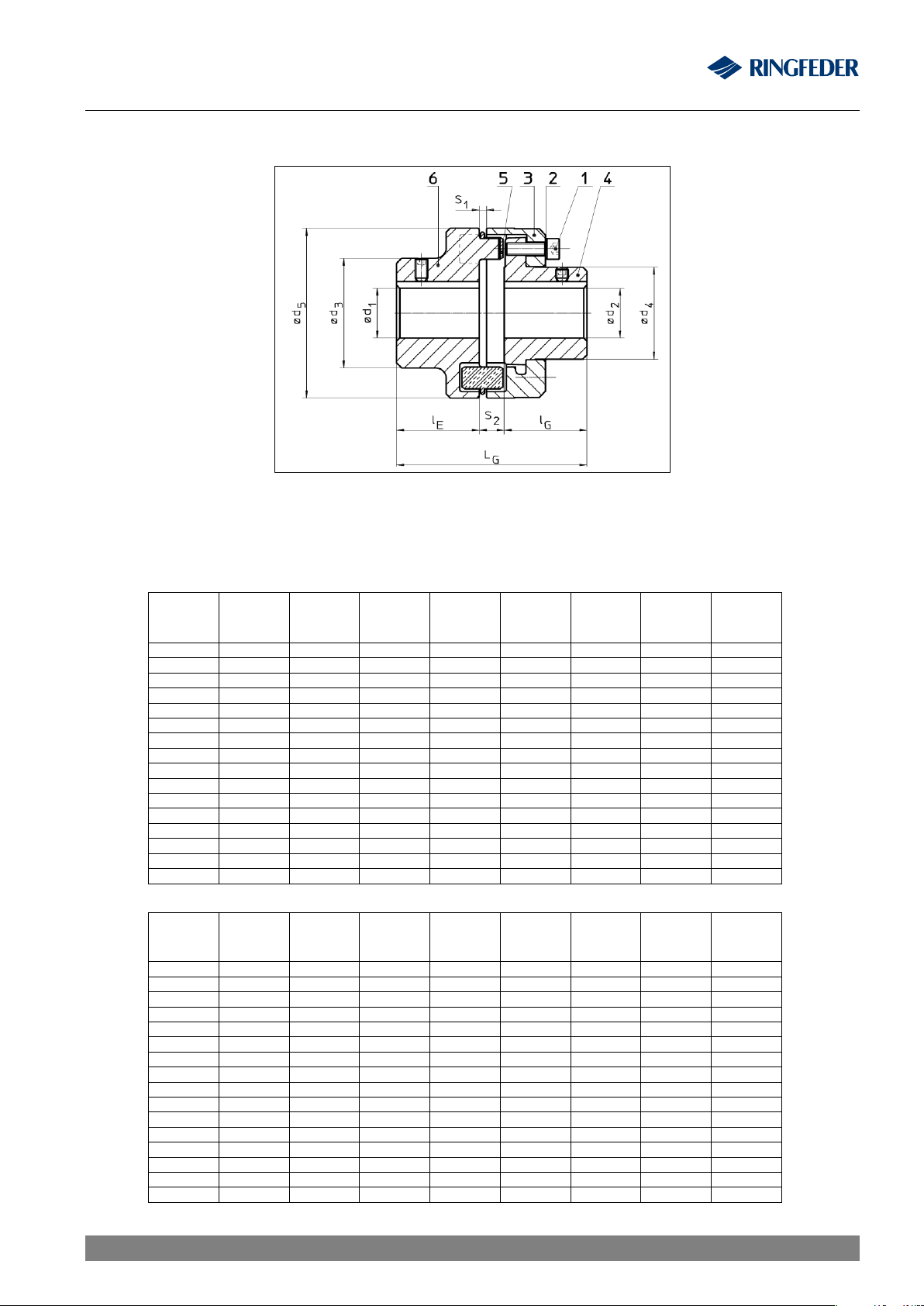

6 Technical data .................................................................................................................. 6

7 Assembly .......................................................................................................................... 8

7.1 Pay attention before the assembly ............................................................................. 8

7.2 Finished borehole ....................................................................................................... 9

7.3 Installing coupling ..................................................................................................... 10

8Adjusting coupling .......................................................................................................... 12

8.1 Angular misalignment Kw ....................................................................................... 13

8.2 Radial displacement Kr ........................................................................................... 13

8.3 Axial displacement ................................................................................................... 14

9Operation ....................................................................................................................... 15

9.1 Sense of rotation test ............................................................................................... 18

10 Maintenance ................................................................................................................... 20

10.1 Wear Inspection on the Buffer Ring ......................................................................... 20

10.2 Wear limit of elastic buffers ...................................................................................... 21

10.3 Changing the elastic intermediate ring ..................................................................... 21

11 Waste Disposal .............................................................................................................. 23

1 Notes on safety

The present assembly and operating instruction (AOI) constituents a part of the coupling

supply. Always keep the AOI near the coupling well accessible.

The German version of this manual is the predominant and binding version.

Make sure that all persons charged with the assembly, operating, service, and maintenance

have read and understood the AOI and follow all the points:

-Avert hazards for body and live of the user and third parties.

-Ensure the operating safety of the coupling.

-Avoid the loss of use and environmental impairment through false handling.

In the case of transport, mounting, dismounting and maintenance, attention is to be paid to

the relevant regulations for industrial safety and for environmental care.

The coupling may only be operated, mounted, serviced and maintained by authorised and

trained personnel.

The user must take into account that the bolting elements of coupling parts may be adversely

affected by the heat produced by a brake disk/ brake drum due to the resultant friction. Make

sure that the combination of the employed brake lining with the material of the brake disk/

brake drum does not lead to sparks or impermissible thermal growth. The brake disk is

RINGFEDER® TNM E

BAWN 002-GBR-2