- 2 -

Contents

Chapter Page

1 Safety Instructions............................................................................................................2

2 Technical Description .......................................................................................................3

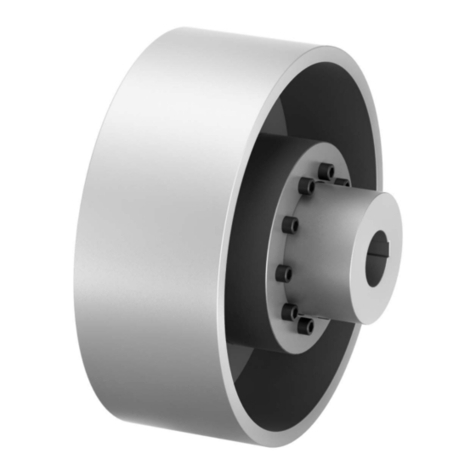

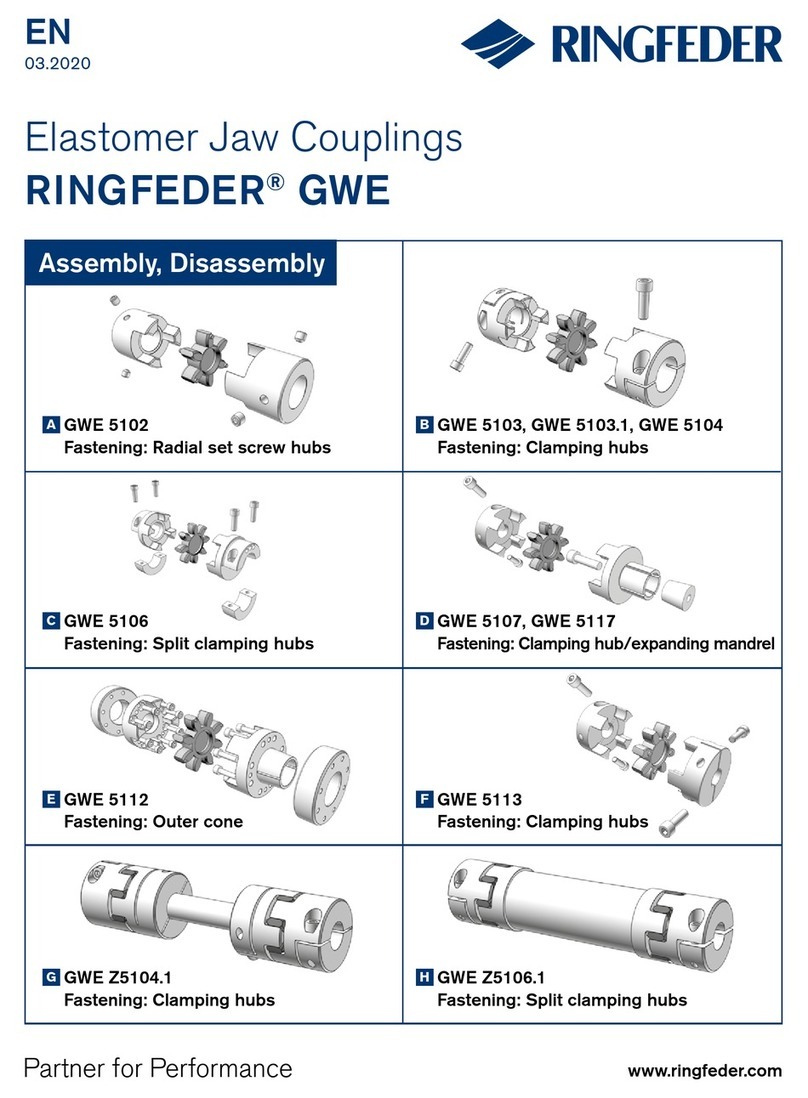

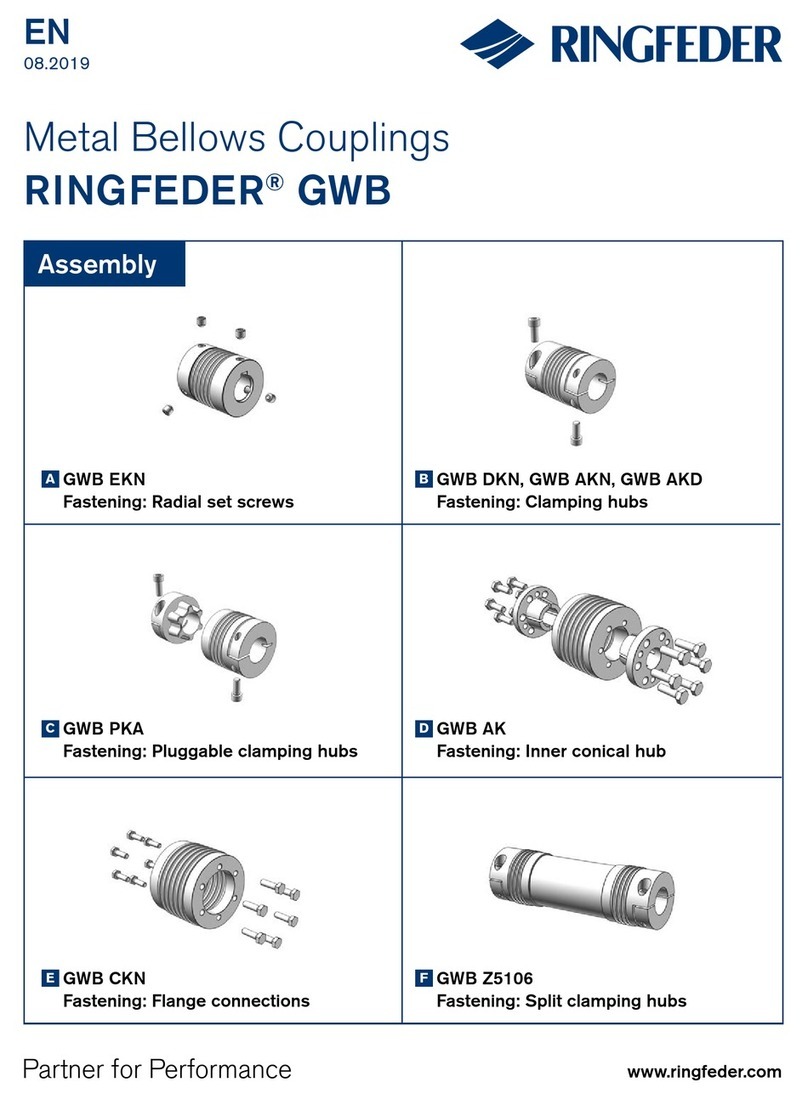

2.1 Intended Application..................................................................................................3

3 Coupling Marking..............................................................................................................4

3.1 Marking of Buffer Rings.............................................................................................4

4 Storage.............................................................................................................................4

5 Construction .....................................................................................................................5

6 Technical Data..................................................................................................................6

7 Installation ........................................................................................................................8

7.1 To be observed prior to installation............................................................................8

7.2 Finish bores...............................................................................................................9

7.3 Coupling installation ................................................................................................10

8 Coupling Alignment ........................................................................................................11

8.1 Angular Misalignment..............................................................................................12

8.2 Radial Misalignment................................................................................................13

8.3 Axial Misalignment...................................................................................................13

9 Operation........................................................................................................................14

10 Maintenance ..................................................................................................................17

10.1 Wear Inspection on the Buffer Ring.........................................................................17

10.2 Wear Inspection - Equipment at standstill ...............................................................18

10.3 Replacement of buffer ring......................................................................................19

11 Disposal.........................................................................................................................19

1 Safety Instructions

This installation and operation manual is an essential component of the coupling

delivery. Always keep this manual in a readily accessible place near the coupling.

Take care that all persons being charged with the installation, operation, maintenance and

repair of the coupling have read and understood this manual and that all instructions con-

tained therein are carefully observed in order to:

-avoid danger to life and limb of the user or third persons,

-ensure the operational safety of the coupling,

-preclude operation failures and environmental damages due to wrong handling and

misuse.

The relevant instructions and regulations regarding safety at work and environmental protec-

tion have to be observed while transporting, mounting and dismounting the coupling.

The coupling shall be operated, mounted, maintained and repaired by authorized, trained and

instructed personnel only.

In the interest of further development, we reserve the right to carry out modifications serving

the technical progress.

BAWS 010-GBR-1 RINGFEDER® TNS SX