Troubleshooting

Problem Solution

Water Freezing in the

Valve, Supply Line, or

Drink Area

Make sure the fountain is sealed from wind between the concrete platform and

bottom of unit

Make sure there are at least 10 animals drinking from only this fountain. (No other

source of water available.)

Make sure incoming water is at least 42oF

Make sure supply line is appropriately insulated:

Foam rubber insulation around supply line

Riser tube with supply line centered, and air space between riser tube

and supply line. Ritchie Thermal Tubes are recommended as they

have optimum inside and outside diameter to maximize insulation (see

part listing page 3)

Horizontal supply line is at least 1 foot below frost line

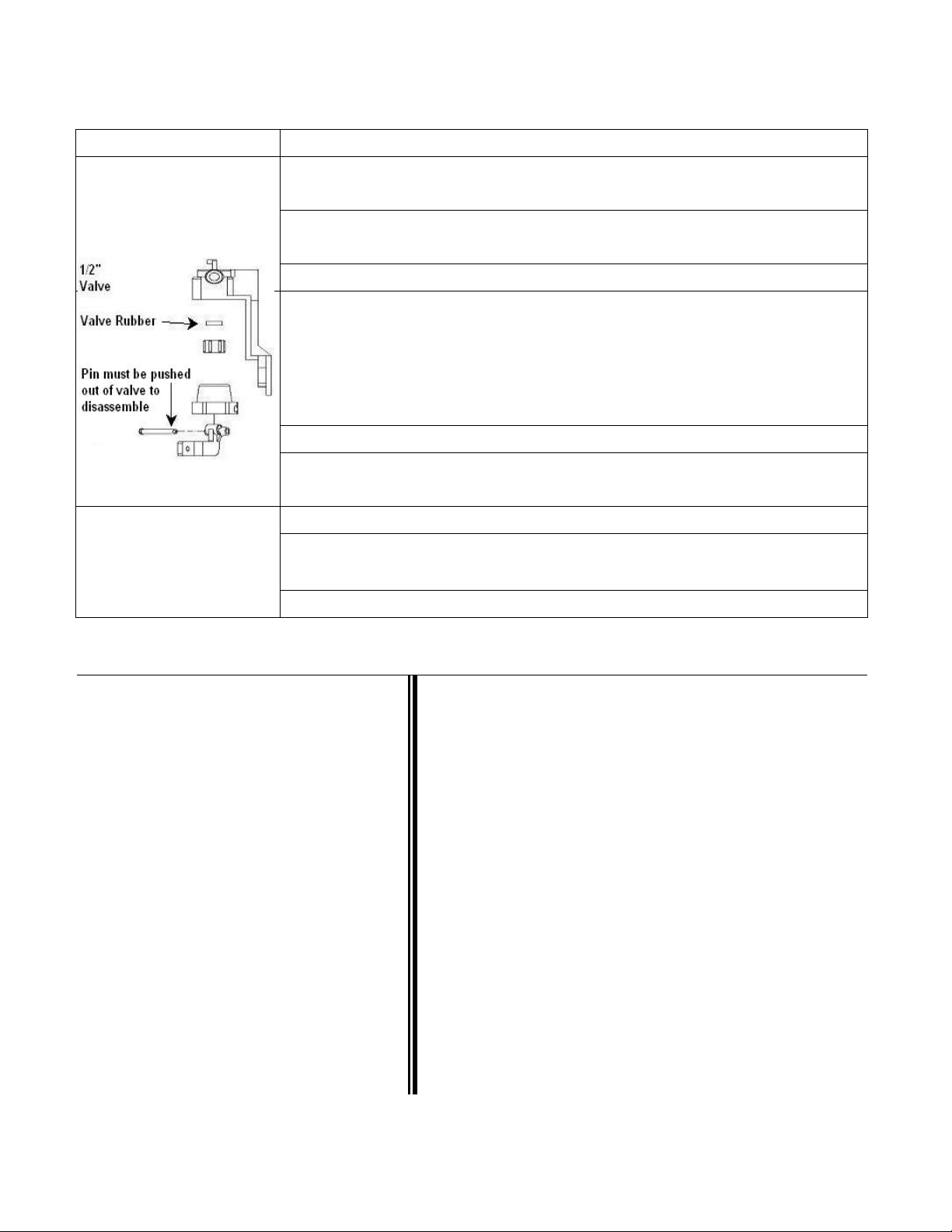

Turn valve rubber over and re-assemble

If the above conditions cannot be met, use supplemental heat as described on page

3

Low Water Flow

Check that valve inlet is not plugged or supply hose is not kinked.

Check system pressure from supply hose by installing a tee and pressure gauge in

front of the valve to check pressure drop when valve is open. A severe pressure

drop indicates a restriction or undersized supply system.

Check that shut off valves are fully open.

Ritchie Limited Warranty Effective September 2012

Ritchie Industries, Inc. warrants its products to

be free of defective materials and workmanship.

Defective part(s) will be repaired or replaced at the

option of Ritchie Industries. This warranty

specifically excludes all labor and shipping

charges.

This warranty does not apply to any appearance

items, to any product whose exterior has been

damaged or defaced, to any product that has been

improperly installed, to any product subjected to

misuse, abnormal service or handling, and to any

products altered or repaired with other than original

equipment or manufacturer’s parts.

This warranty gives you specific legal rights,

and you may also have other rights which may vary

from state to state.

All warranty claims must be processed through

an Authorized Ritchie Dealer/ Distributor. Proof of

purchase is required. The period of warranty begins

at original date of purchase as follows:

Poly Units

Base, top and ball closures

10 year limited against manufacturing defect. 100% first five

years, then declining 20% per year for the remaining five years.

Stainless Steel Units

Stainless trough and stainless valve chamber frame:

Ten years against manufacturing defect or corrosion. 100% all

ten years.

Casing and cover:

10 year limited against manufacturing defect. 100% first year,

then declining 10% per year for the remaining nine years.

Component Parts

All component parts, such as floats, valves, heating elements:

One year from the date of purchase against manufacturing defect,

100%.

Hydrants

All component parts:

One year from the date of purchase against manufacturing defect,

100%.

Thrifty King Swine Instruction Manual