ROBOTIQ AirPick User manual

Other ROBOTIQ Robotics manuals

ROBOTIQ

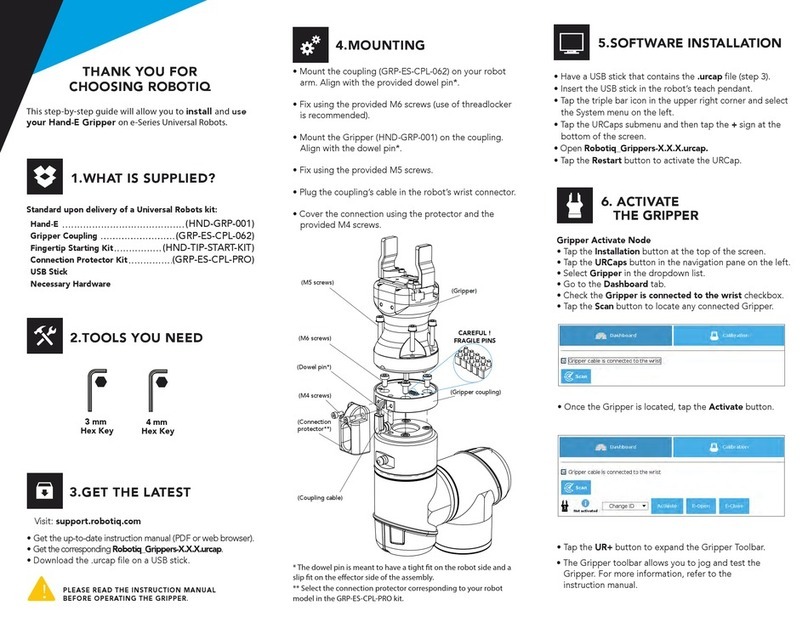

ROBOTIQ HAND-E User manual

ROBOTIQ

ROBOTIQ AIR PICK User manual

ROBOTIQ

ROBOTIQ CNC Machine Tending Kit User manual

ROBOTIQ

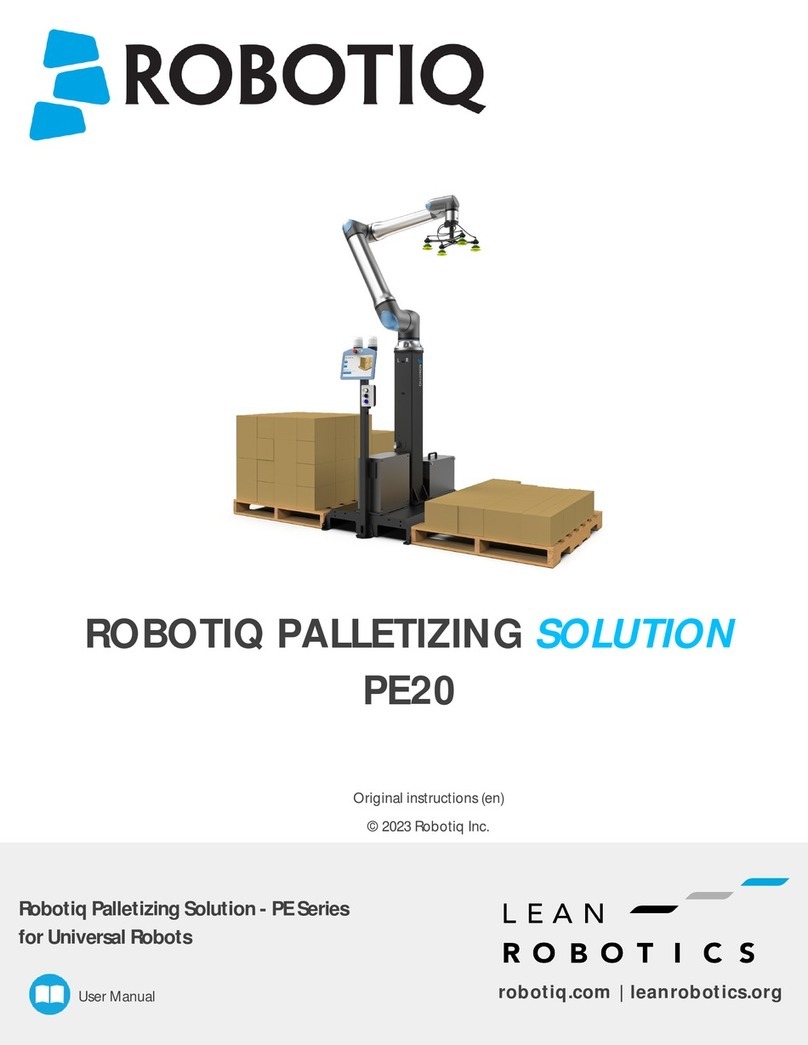

ROBOTIQ PE Series User manual

ROBOTIQ

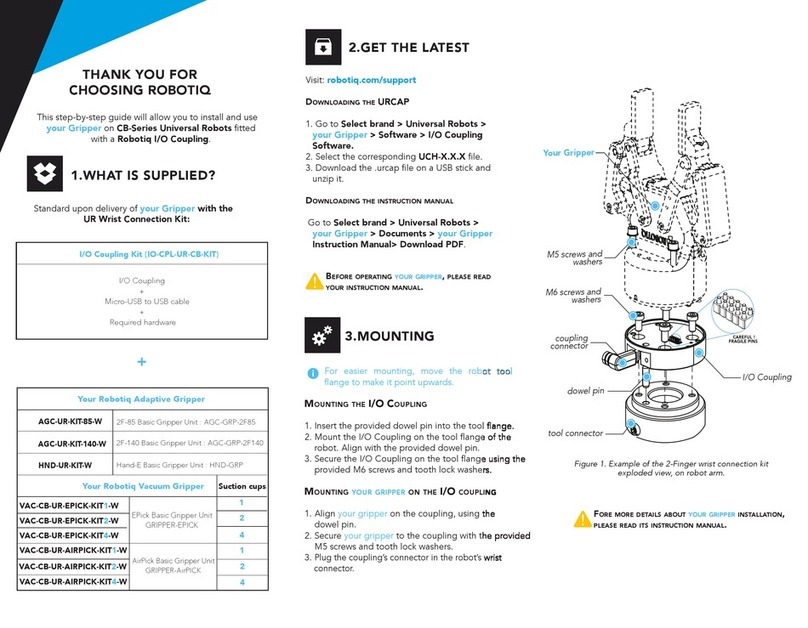

ROBOTIQ CB Series User manual

ROBOTIQ

ROBOTIQ 2-Finger Adaptive Robot Gripper - 200 User manual

ROBOTIQ

ROBOTIQ AirPick User manual

ROBOTIQ

ROBOTIQ SD-100 User manual

ROBOTIQ

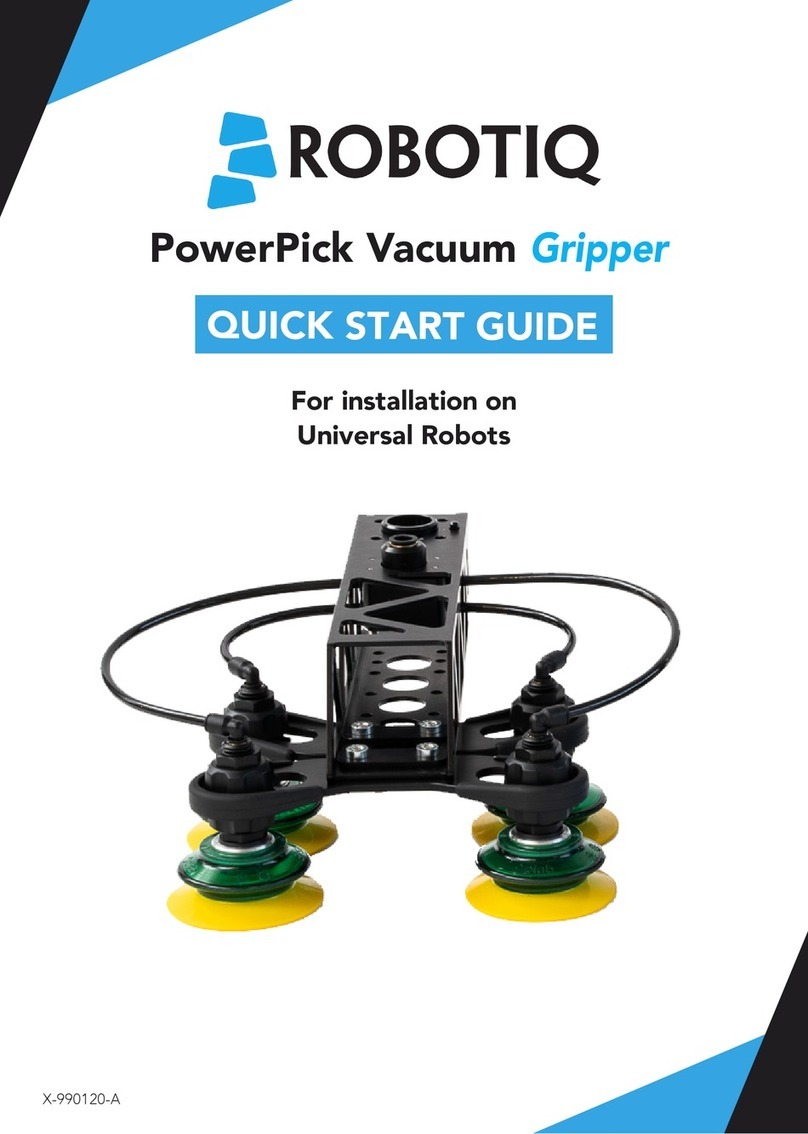

ROBOTIQ PowerPick Vacuum Gripper User manual

ROBOTIQ

ROBOTIQ 2F-85 User manual

ROBOTIQ

ROBOTIQ HAND-E User manual

ROBOTIQ

ROBOTIQ PE20 User manual

ROBOTIQ

ROBOTIQ HAND-E User manual

ROBOTIQ

ROBOTIQ 3-Finger Adaptive Robot Gripper User manual

ROBOTIQ

ROBOTIQ HAND-E User manual

ROBOTIQ

ROBOTIQ 2F-85 User manual

ROBOTIQ

ROBOTIQ 56854B User manual

ROBOTIQ

ROBOTIQ Sanding Kit User manual

ROBOTIQ

ROBOTIQ EPick User manual

ROBOTIQ

ROBOTIQ Wrist Camera User manual