Introduction...............................................................................................................................................5

1.1. Description.........................................................................................................................................5

1.2. Validity of documentation ..............................................................................................................5

1.3. Who should use this documentation..............................................................................................5

1.4. Use of the product............................................................................................................................5

1.5. Safety precautions ...........................................................................................................................5

1.7. Acronyms............................................................................................................................................6

Product......................................................................................................................................................7

2.1. Main features....................................................................................................................................7

2.2. Type selection...................................................................................................................................7

2.3. Operating modes.............................................................................................................................8

2.3.1. SIO mode.....................................................................................................................................8

2.3.2. IO-Link mode...............................................................................................................................8

2.3.3. Process data ...............................................................................................................................9

2.4. Output Parameters...........................................................................................................................9

2.4.1. Sensor front................................................................................................................................10

2.4.1.1. SSC (Switching Signal Channel)........................................................................................10

2.4.1.2. Switchpoint mode:.............................................................................................................10

2.4.1.3. Hysteresis Settings ...............................................................................................................11

2.4.1.4. Temperature alarm (TA).....................................................................................................11

2.4.1.5. External input ......................................................................................................................11

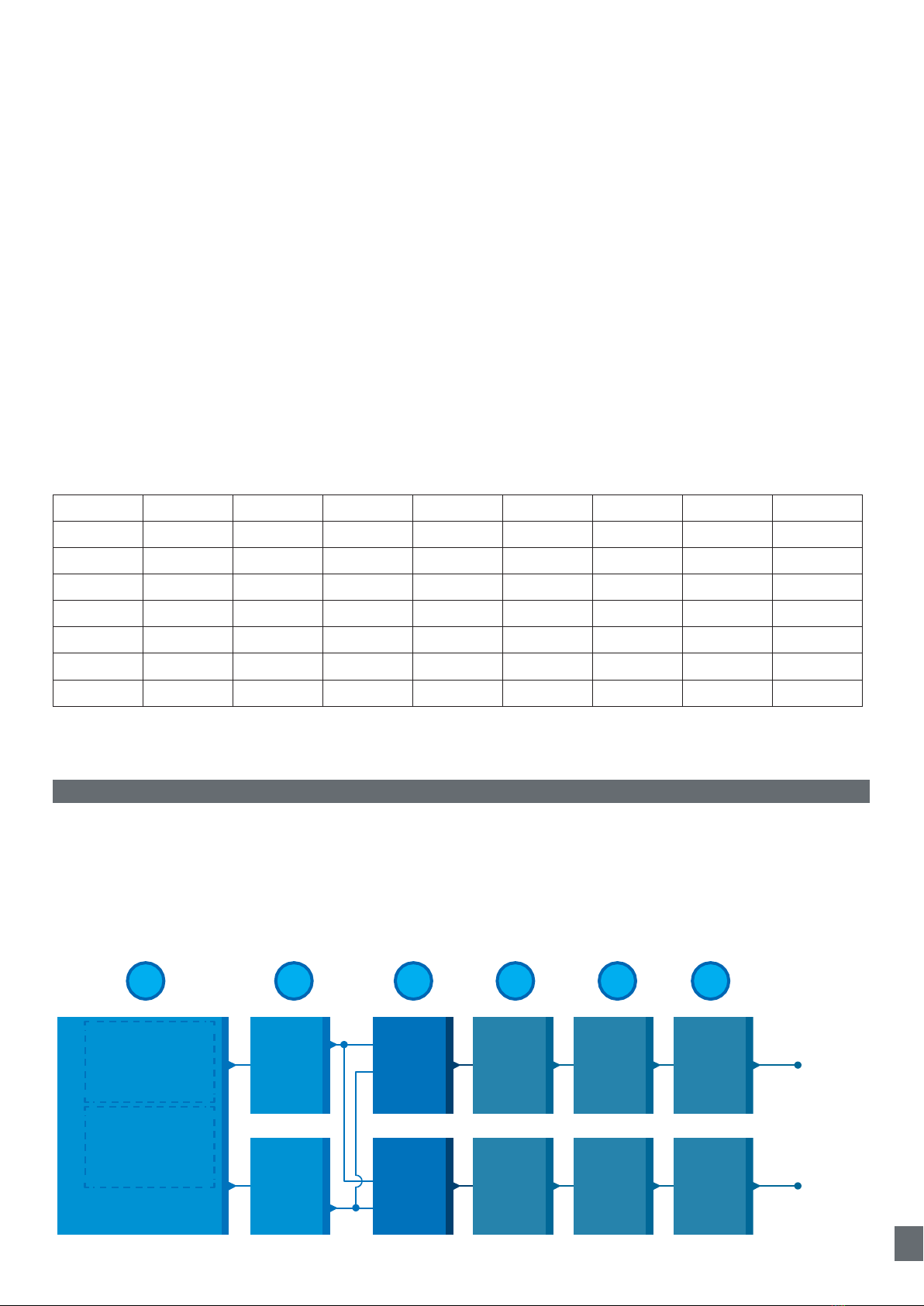

2.4.2. Input selector ............................................................................................................................12

2.4.3. Logic function block ................................................................................................................12

2.4.4. Timer (Can be set individually for Out1 and Out2)...............................................................14

2.4.4.1. Timer mode .........................................................................................................................14

2.4.4.1.1. Disabled........................................................................................................................14

2.4.4.1.2. Turn On delay (T-on)....................................................................................................14

2.4.4.1.3. Turn Off delay (T-off)....................................................................................................15

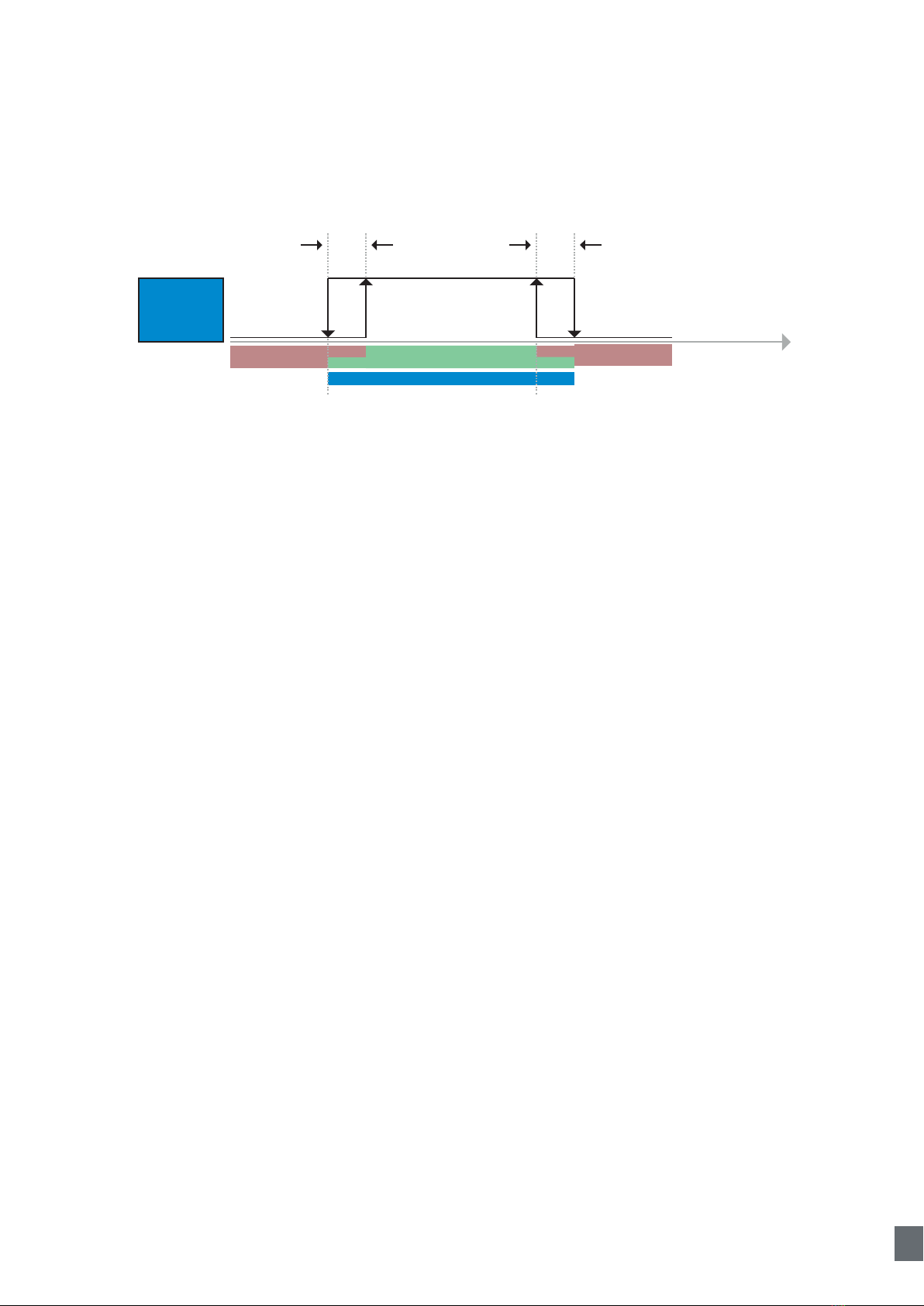

2.4.4.1.4. Turn ON and Turn Off delay (T-on and T-off) ............................................................15

2.4.4.1.5. One shot leading edge..............................................................................................16

2.4.4.1.6. One shot trailing edge................................................................................................16

2.4.4.2. Timer scale...........................................................................................................................16

2.4.4.3. Timer Value..........................................................................................................................16

2.4.5. Output Inverter .........................................................................................................................17

2.4.6. Output stage mode .................................................................................................................17

2.5. Teach procedure............................................................................................................................18

2.5.1. External Teach (Teach-by-wire)..............................................................................................18

2.5.2. Teach from IO-Link Master.......................................................................................................18

2.5.2.1. Single point mode procedure...........................................................................................18

2.5.2.2. Two point mode procedure..............................................................................................19

2.5.2.3. Windows mode procedure...............................................................................................20

2.6. Sensor Specific adjustable parameters .......................................................................................21

2.6.1. Selection of local or remote adjustment...............................................................................21

2.6.2. Trimmer data.............................................................................................................................21

2.6.3. Process data configuration.....................................................................................................21

2.6.4. Sensor application setting.......................................................................................................21

2.6.5. Temperature alarm threshold..................................................................................................21

2.6.6. Event configuration..................................................................................................................22

2.6.7. Quality of run QoR....................................................................................................................22

2.6.8. Quality of Teach QoT ...............................................................................................................22

2.6.9. Filter Scaler ................................................................................................................................23

Rs Components Ltd