13/08/2017 Version No. 001

MeterScope/English MeterScope/English

13/08/2017 Version No. 001 54

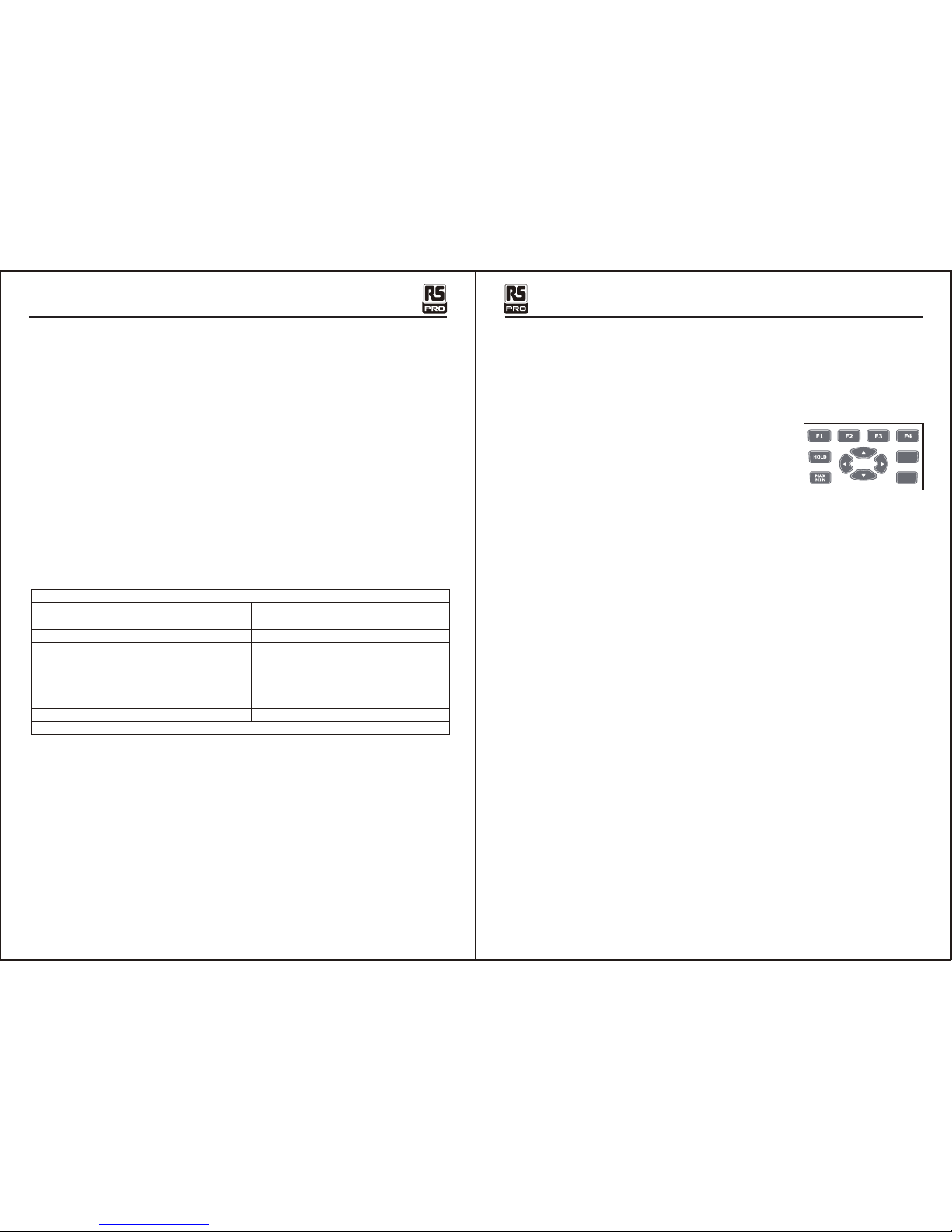

1.Soft key labels Indicates the function of the button just below the displayed label.

2.Bar graph Analog display of the input signal(See the "Bar Graph" section for more information).

3.Minus sign Indicates a negative reading.

4.Indicates the range the Meter is in and the ranging mode (auto or manual)

5.Battery level Indicates the charge level batteries.

6.Time Indicates the time set in the internal clock.

7.Mode annunciators Indicates the Meter's mode.

8.Minimeasurement Displays the lightning bolt (when necessary) and the input value when the

primary and secondary displays are covered by a menu or pop-up message.

9.Main display Displays measurement information about the input signal.

10.Date Indicates the date set in the internal clock.

11.Beeper Indicates the Meter’s beeper is enabled (not associated with the continuity beeper).

12.Units Indicates the units of measurement. Auxiliary Units Indicates unit less measurements

like Crest Factor.

13.Blue tooth Indicates activity over the communication link.

14.Relative Indicates the displayed value is relative to a reference value.

15.Secondary display Displays secondary measurement information about the input signal.

4-2.Understanding the Display 4-4.Page Area

The page area of the display is where the main meter content is displayed.

The primary display (upper half of the page area) is where the most important value of the selected

function is shown. The secondary display contains the bar graph and values that may be measured

in addition to the primary function value. For example, with frequency measurement selected in Vac,

the frequency value will appear in the primary display with the ac voltage value in the secondary

display.

4-5.Softkey Labels

Labels for the four function softkeys (F1 through F4) appear in the bottom row of the display.

These labels will change based on the function and/or menu selection.

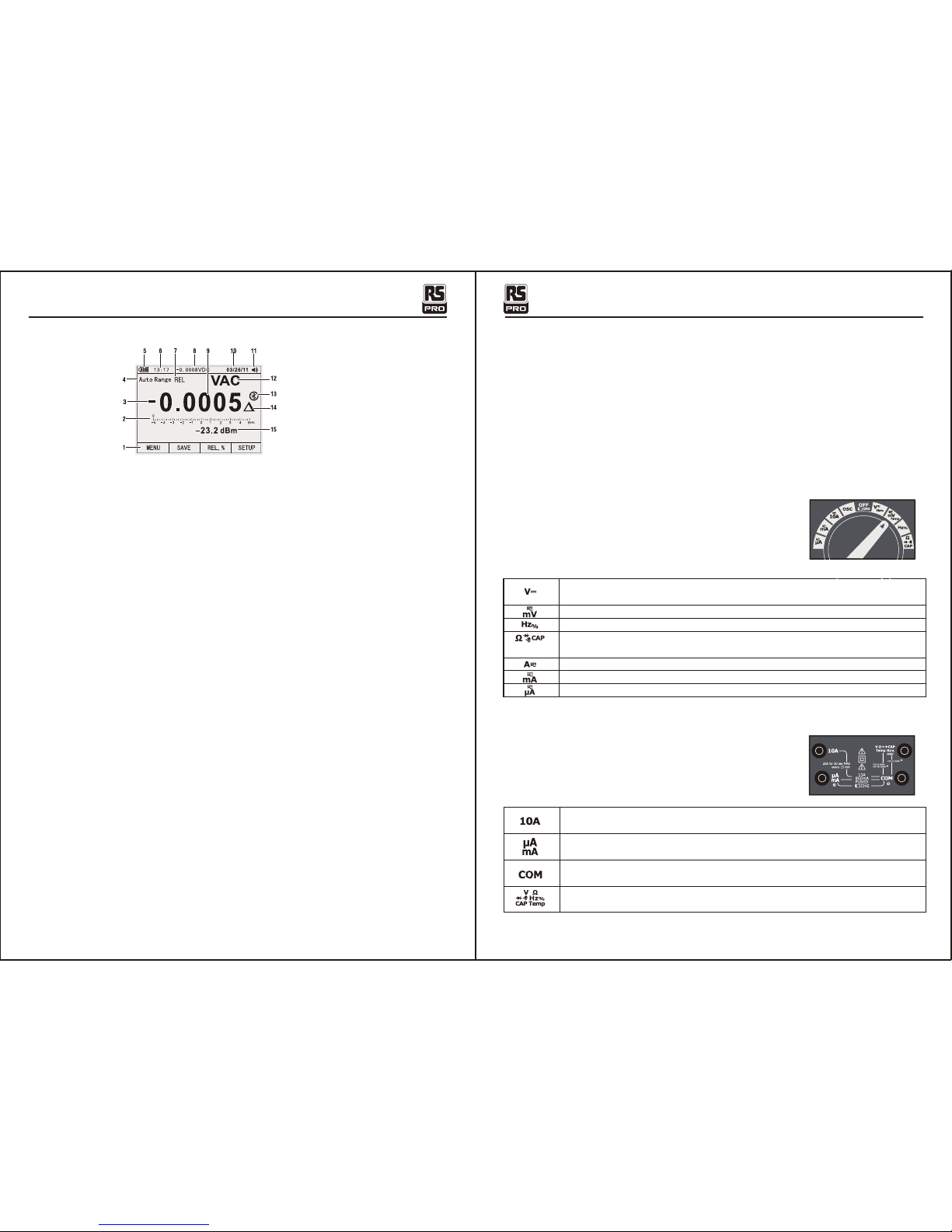

4-6.Understanding the Rotary Switch

Select a primary measurement function by positioning the rotary

switch to one of the icons around its perimeter. For each function,

the Meter presents a standard display for that function (range,

measurement units, and modifiers). Button choices made in one

function do not carry over into another function.

4-7.Using the Input Terminals

All functions except current use the VOHMSand COM input

terminals. The two current input terminals (A and mA/μA) are

Used as follows:

Current from 0 to 500 mA, use the uAmA and COM terminals.

Current between 0 and 10 A use the A and COM terminals.

Input for 0 A to 10.00 A current (20VA overload for 30 seconds

on, 10 minutes off),

Input for 0 A to 500 mA current measurements.

Return terminal for all measurements.

Input for voltage, continuity, resistance, diode test, conductance,

capacitance.

DC(AC) and AC+DC voltage measurements

AC voltage measurements

DC(AC) millivolts, ac+dc millivolt measurements

Frequency measurements

Resistance, Diode test, Capacitance and Continuity measurements

Temperature measurements

AC, DC and AC+DC amps measurements

AC, DC and AC+DC milliamps measurements

AC, DC and AC+DC microampere measurements up to 5,000μA