2

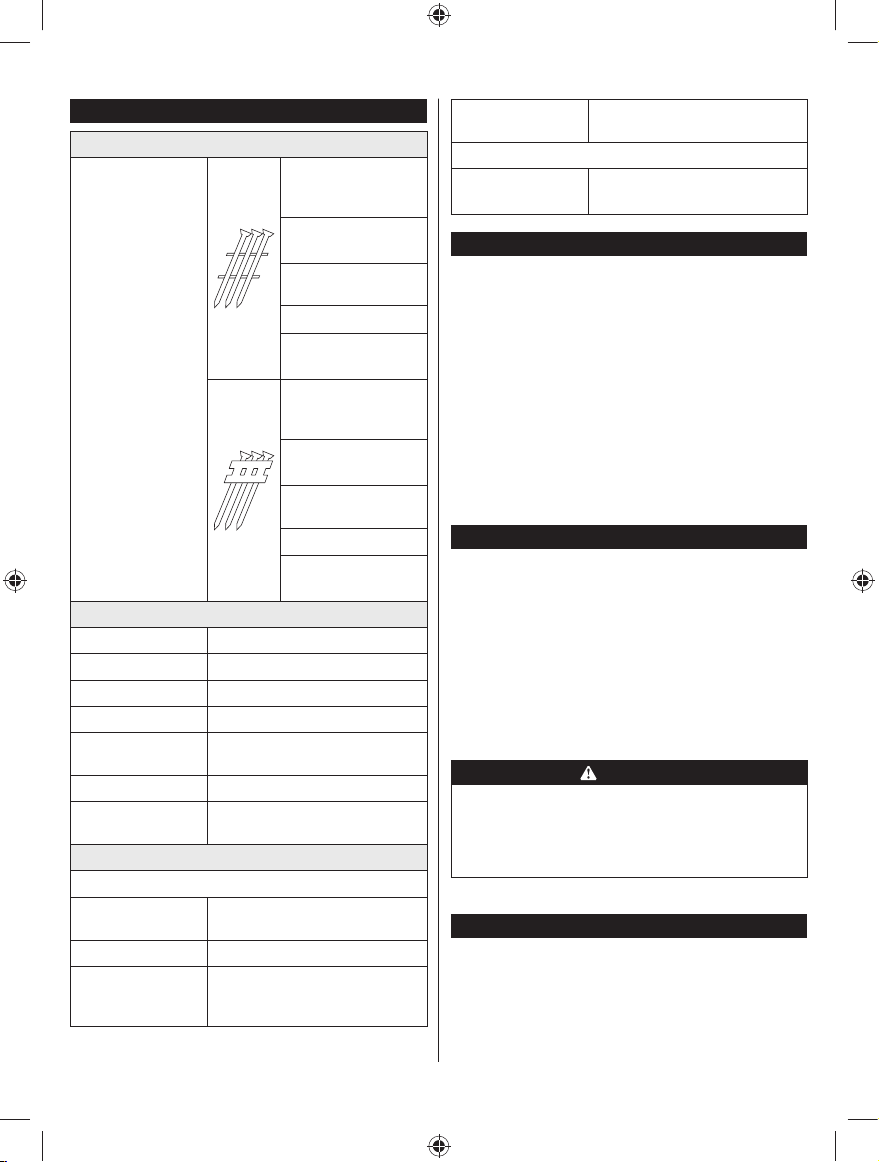

INFORMATION ON MECHANICALIMPACT(VIBRATION)

The characteristic vibration values for the fastener driving

tool have been determined in accordance with ISO 8662-

11:1999 and EN 12096 – Measurement of vibration in

hand-held power tools – Part 11: Fastener driving tools

VHH6SHFL¿FDWLRQV

This value is a tool-related characteristic value and does

QRWUHSUHVHQWWKHLQÀXHQFHWRWKHKDQGDUPV\VWHPZKHQ

XVLQJWKHWRRO$QLQÀXHQFHWRWKHKDQGDUPV\VWHPZKHQ

using the tool will for example depend on the gripping

force, the contact pressure force, the working direction,

the adjustment of compressed air supply, the workplace

and the work piece support.

ADDITIONAL SAFETY INSTRUCTIONS FOR

PNEUMATIC POWER TOOLS

ŶAir under pressure can cause severe injury.

ŶAlways shut off air supply, drain hose of air pressure

and disconnect tool from air supply whenever not in

use, before changing accessories or where making

repairs.

ŶNever direct air at yourself or anyone else.

ŶWhipping hoses can cause severe injury. Always

check for damaged or loose hoses and fittings.

ŶCold air should be directed away from the hands.

ŶWhenever universal twist couplings (claw couplings)

are used, lock pins shall be installed and whip check

safety cables shall be used to safeguard against

possible hose-to-tool and hose-to-hose connection

failure.

ŶDo not exceed the maximum air pressure stated on

the tool.

ŶNever carry an air tool by the hose.

ŶOnly fasteners listed in the specifications may be used

in the fastener driving tool. The fastener driving tool

and the fasteners specified in the specifications are to

be considered as one unit safety system.

ŶQuick action couplings shall be used for connection

to the compressed air system and the non-sealable

nipple must be fitted at the tool in such a way that no

compressed air remains in the tool after disconnection.

ŶOxygen or combustible gases shall not be used as an

energy source for compressed air operated fastener

driving tools.

ŶFastener driving tools shall only be connected to an

air supply where the maximum allowable pressure of

the tool cannot be exceeded by more than 10%; in the

case of higher pressure ,a pressure reducing valve

which includes a downstream safety valve shall be

built into the compressed air supply.

ŶOnly the main energy and the lubricants listed in

the operating instructions may be used for the

maintenance of fastener driving tools. Only spare

parts specified by the manufacturer or his authorised

representative shall be used.

ŶRepairs shall be carried out only by the manufacturer's

authorized agents or by other experts, having due

regard to the information given in the operating

instructions.

ŶStands for mounting the fastener driving tools to a

support, for example to a work table, shall be designed

and constructed by the stand manufacturer in such

a way that the fastener driving tools can be safely

fixed for the intended use, thus for example avoiding

damage, distortion and displacement.

ŶCheck prior to each operation that the safety and

triggering mechanism is functioning properly and that

all nuts and bolts are right.

ŶDo not carry out any alterations to the fastener driving

tool.

ŶDo not disassemble or make inoperative any parts of

the fastener driving tool such as the safety yoke.

ŶDo not perform any “emergency repairs” without

proper tools and equipment.

ŶThe fastener driving tool should be serviced properly

and at regular intervals in accordance with the

manufacturer’s instructions.

ŶAvoid weakening or damaging the tool, for example

by:

– punching or engraving;

– modification not authorized by the manufacturer;

– guiding against templates made of hard material

such as steel;

– dropping or pushing across the floor;

– using the tool as a hammer;

– applying excessive force of any kind.

ŶNever point any fastener driving tool at yourself or at

any other person or animal.

ŶHold the fastener driving tool during the work operation

in such a way that no injuries can be caused to the

head or to the body in the event of possible recoil

consequent upon a disruption in the compressed air

supply or hard areas within the workplace.

ŶNever actuate the fastener driving tool into free space.

This will avoid any hazard caused by free flying

fasteners and excessive strain of the tool.

ŶThe tool shall be disconnected from the compressed

air system for the purpose of transportation, especially

where ladders are used or where an unusual physical

posture is adopted whilst moving .

ŶCarry the fastener driving tool at the workplace using

only the handle, and never with the trigger actuated.

ŶTake conditions at the workplace into account.

Fasteners can penetrate thin work pieces or slip off

corners and edges of workplaces, and thus put people

at risk.

ŶFor personal safety, use protective equipment such as

hearing and eye protection.

ŶFastener driving tools are operated by actuating the