10

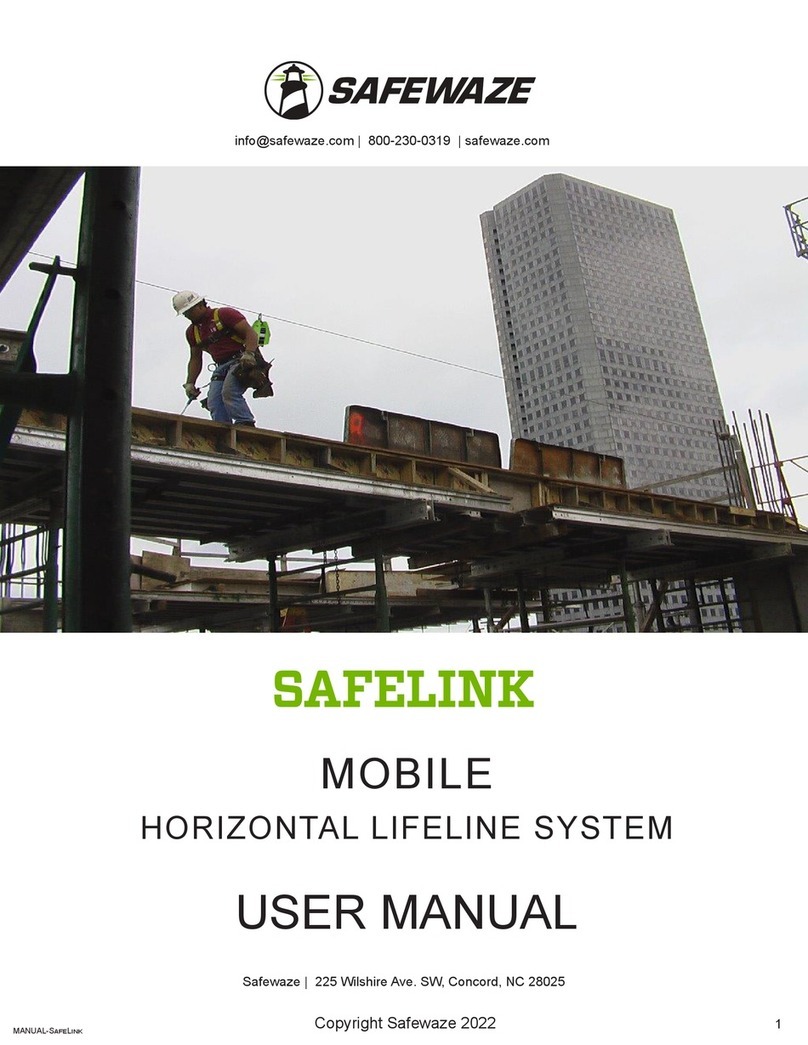

Mobile SAFELINK Horizontal Lifeline System User Manual

V2.5 Copyright SafeWaze 2020

DO NOT USE A PVC SLEEVE

THAT DOES NOT MEET ALL OF

THESE REQUIREMENTS.

Installation of PVC Sleeve for

Aluminum Post

Cut PVC sleeves to 12 in (304.8

mm), and cast sleeves into freshly

poured concrete of 2,000 PSI (13.8

MPa) or greater. Use duct tape to

seal the ends of the PVC sleeve,

preventing fresh concrete from

filling the sleeve. The PVC sleeve

must not be cast into concrete

within 3-1/2 in (88.9 mm) of any

concrete edge. When stirrups

exist in the column within 2-1/2 in

(63.5 mm) of the top surface, the

minimum column size must be no

less than 12 in (304.8 mm) in either

direction. When no stirrups exist,

the minimum column size must be

no less than 17 in (431.8 mm).

PVC sleeve should be plumb and

must be cast to a minimum depth of

11 in (279.4 mm). Ensure the PVC

sleeves do not float upwards in

the concrete before it sets. To help

keep sleeves from floating, punch

a small air hole through the duct

tape on the bottom of the sleeve,

and use a vertical 2x4 in the sleeve,

nailed to the top of the form. This

method will also help ensure the

sleeve stays plumb.

A sleeve should normally be placed

at the center of the column section.

This will minimize the tendency to

split the column. When sleeves are

placed at the center of the column

section, and when column ties exist

in the concrete within 2-1/2 in (63.5

mm) of the top surface (thereby

crossing the potential fracture

surface), the minimum column

size permitted is 12 in (304.8

mm) measured perpendicular to

the direction of the span of the

lifeline system. When there are

no such ties, the minimum column

dimension measured perpendicular

to the span of the lifeline system is

17 in (431.8 mm). Sleeves should

never be placed closer than 3-1/2

in (88.9 mm) to any edge of the

column cross-section.

When possible, request that a

column tie be located approximately

2 in (50.88 mm) below the top

surface of the column pour (Only

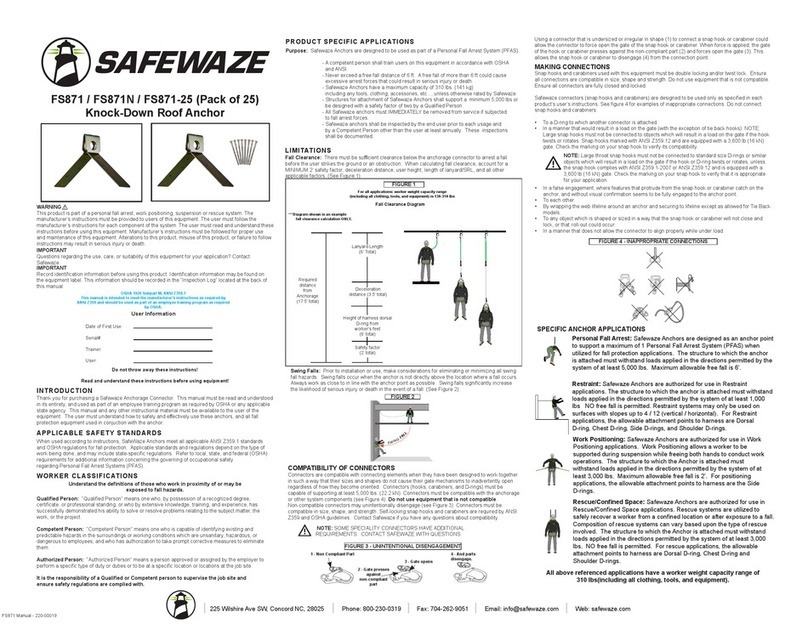

*Only one tie

shown for clarity

Sleeve no closer than

3-1/2 in (88.9 mm)

to any side of the column

17 in (431.8 mm) minimum

with tie > 2-1/2 in (63.5

mm) below top of concrete

12 in (304.8 mm) minimum

with tie < 2-1/2 in (63.5 mm)

below top of concrete

Depth of

column tie

Fig. 1

INSTALLATION—ANCHORAGE CONNECTORS 9

one tie shown in

Figure1 for clarity).

The aluminum post

is 7 ft-6 in (2.29

m) long. With a

12 in (304.8 mm)

embedded sleeve

to support the post,

the height of the

horizontal lifeline is

approximately 6 ft-6

in (1.98 m) above

the poured height

of the column. At

this height, the average employee

should pass easily under the cable

and conveniently reach it to attach

a self-retracting device.

It is easier and safer to assemble

as much of the SAFELINK Sys-

tem as possible before raising the

assembly to the elevated location.

Generally, the horizontal lifeline

can be attached to the posts before

inserting the posts into the column

tops. Final tension of the horizontal

lifeline, however, must always be

completed with the posts set into

the sleeves.

Reinforced Cross-Arm Strap

To secure the Cross-Arm Strap,

wrap the strap around the concrete

column at a height of at least 6

ft-6 in (1.98 m) above the walking

/ working surface using a choker

hitch. This is done by passing

one end of the strap through the

other end and cinching. Attach

the STOPLINK Brake by use of a

carabiner. Secure the other end of

the lifeline to column by tensioning

the line as required.

10,000 lb (4535.92 kg) Removable

Concrete Anchor

The Removable Concrete Anchor

is a reusable concrete anchor

designed to be used with horizon-

tal lifelines. This device is made

for use with concrete columns or

walls with a compressive strength

of 3,000 PSI (20.7 MPa). The

10,000-lb (4535.92 kg) rating is in

any direction up to 90º when placed

in concrete. Install the anchor in

accordance with user instructions.

Attach STOPLINK Brake by use

of carabiner to Concrete Anchor

eyelet.

RebarLink

The RebarLink Bracket is to be

installed 6-1/2 ft (1.98 m) above

the working surface. With the

eye-bolt facing outward, place the

bracket face perpendicular to the

front of the rebar, centered on the

cage. Slide the supplied cinching

rebar bolts through both plates

and tighten together with supplied

wing nuts so that the Rebar Link is

tightened onto the rebar cage

(See Figure 2).

NOTE: When using the RebarLink,

Aluminum Posts are not used.

FormLink

The FormLink Bracket must be

attached to the base of a rebar

cage. Receiver sleeve must face

the direction of tension in the

system. To attach the FormLink

Bracket to the base of the rebar

cage, place the front and back

bracket at the top of the concrete

base. Slide the threaded bars

through the holes on the front

bracket into the slots of the back

bracket. The front and back panels

of the FormLink Bracket must

capture a minimum of six (6) #7 or

larger rebar, two (2) with the front

panel and two (2) with the back

panel, with the threaded bars.

Hand-tighten all four (4) wing nuts,

then add an additional 1/2 in (12.7

mm) turn to secure.

INSTALLATION—ALUMINUM POSTS 10

Insert Aluminum Post

Each Aluminum Post has two (2)

sets of 9/16 in (14.29 mm) holes set

4 in (101.6 mm) apart and at 90º for

the eye-bolts. Install eye-bolts into

the Aluminum Post.

Insert aluminum post into PVC

Sleeve, or applicable receiver

sleeve on the anchorage connector.

Concrete must have a cured

compressed strength of 2,000

PSI (13.8 MPa) for system use.

Aluminum post must be inserted into

PVC sleeve.

RebarLink

Fig. 2