5/45

TABLE OF CONTENTS

1. INTRODUCTION ..................................................................................................................7

1.1. Applicability.....................................................................................................................7

1.2. Acronyms........................................................................................................................7

1.3. Symbols..........................................................................................................................8

1.4. Referenced documents...................................................................................................8

2. UNPACKING AND INSPECTION.........................................................................................9

2.1. Battery characteristics...................................................................................................11

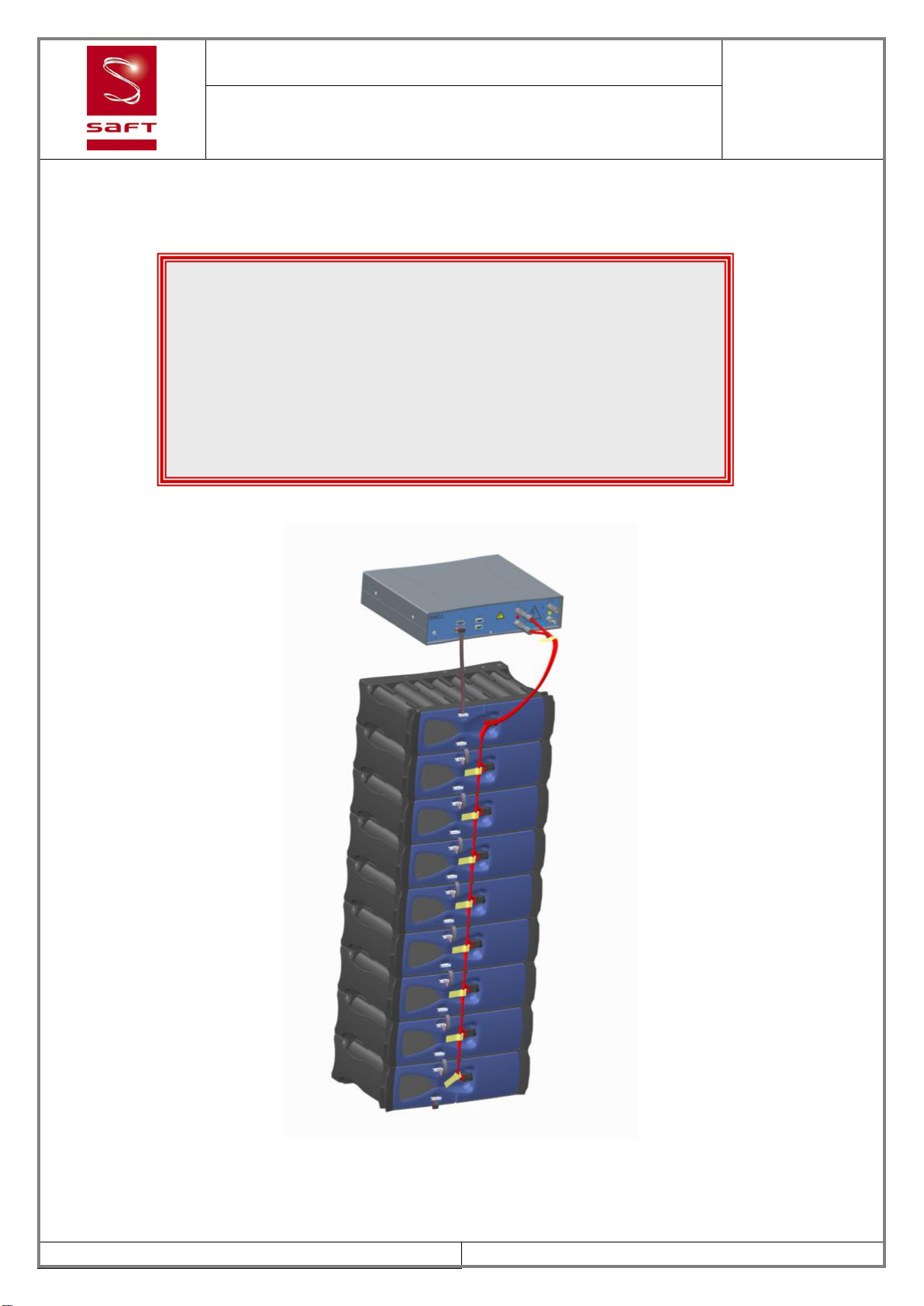

3. GENERAL DESCRIPTION OF THE BATTERY SYSTEM.................................................13

3.1. Synoptic........................................................................................................................13

3.2. Battery system..............................................................................................................14

3.2.1. Li-ion Modules........................................................................................................14

3.2.2. BMM.......................................................................................................................14

3.3. HMI...............................................................................................................................15

3.4. Assembly installation ....................................................................................................16

3.5. Battery start-up.............................................................................................................16

3.6. Battery shutdown..........................................................................................................16

3.7. Gas exhaust..................................................................................................................16

3.8. Electrical interfaces.......................................................................................................17

3.8.1. Power connection...................................................................................................17

3.8.2. Electrical connection ..............................................................................................17

3.8.3. Communication connector......................................................................................19

3.8.4. Power supply connector.........................................................................................19

3.8.5. Earth connection ....................................................................................................19

3.8.6. Diagnostic interface................................................................................................20

4. BATTERY MANAGEMENT and Operating instructions.................................................21

4.1. General principle...........................................................................................................21

4.2. Safety functions ............................................................................................................21

4.2.1. Over charge protection...........................................................................................21

4.2.2. Over-discharge protection......................................................................................22

4.2.3. Over temperature protection...................................................................................22

4.2.4. Over current protection...........................................................................................22

4.3. Communication.............................................................................................................23

4.4. Operation during storage & maintenance .....................................................................23

4.5. Operational states.........................................................................................................24

4.6. Precharge .....................................................................................................................25

4.7. Battery charging............................................................................................................26

4.8. Charge profile description.............................................................................................26

4.9. Battery discharging.......................................................................................................28

4.10. Complete discharge & sleep mode............................................................................28

4.11. Alarms and warnings.................................................................................................28

4.12. Balancing...................................................................................................................29

4.13. Displayed information................................................................................................29

4.14. Communication with application................................................................................29

4.14.1. Data sent by BMM to EMS..................................................................................29

4.14.2. Data received by BMM from EMS.......................................................................30

4.15. SOH and EOL definitions...........................................................................................31

4.16. SOC definitions..........................................................................................................31

5. COMMISSIONING AFTER LONG STORAGE...................................................................31

6. HANDLING & STORAGE OF THE BATTERY MODULES................................................33

6.1. Handling........................................................................................................................33

6.2. Storage.........................................................................................................................33

6.2.1. Storage location .....................................................................................................33