11

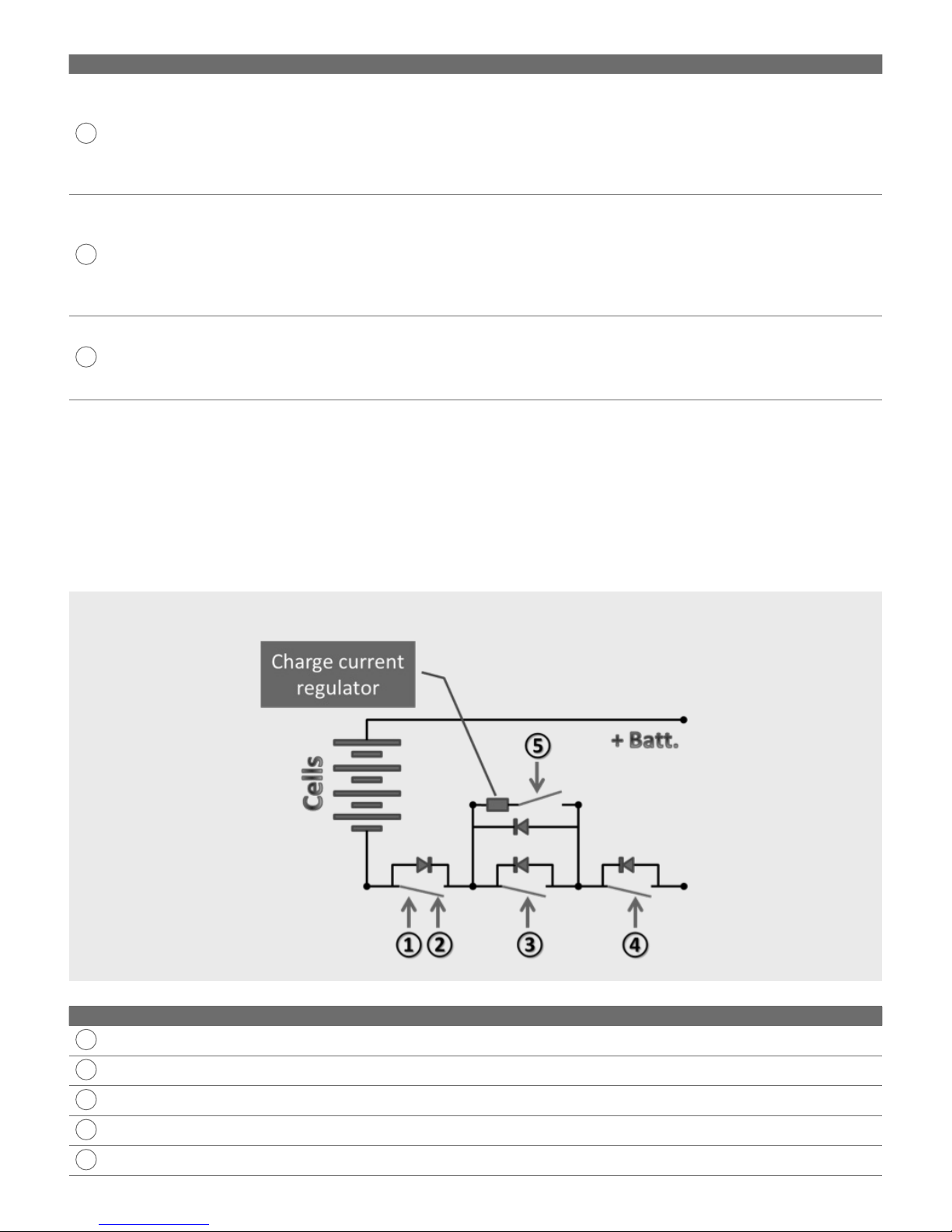

4.3 Operating modes

In all modes except sleep mode, the terminal voltage is present, the RS485 communication is active, the LED’s operate and the dry

contactor operates. Each Evolion controls its own switch state, independent of other parallel connected modules, without the need of

an external master battery management module.

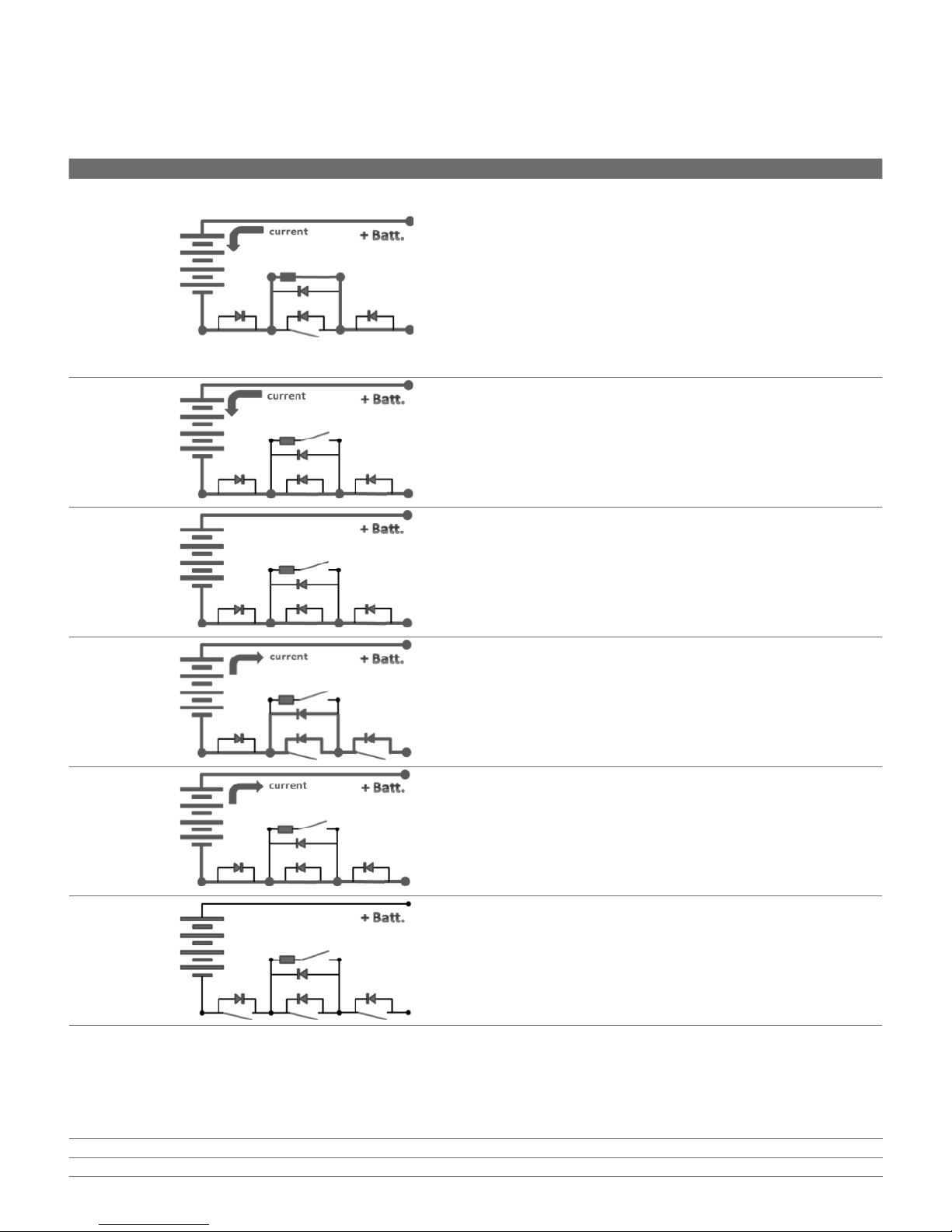

Mode Schematic Description

Regulated

charge

Charge current is accepted anytime the network voltage is higher than

the Evolion terminal voltage. Current is accepted through the current

regulation device. If the charge current exceeds the maximum allowed

charge current (See Charging section), the charge regulated mode

becomes active. The current will be limited and the excess charge energy

dissipates through the front face heat sink. The surface of the heat sink

will be “hot” during which is normal for regulated charge mode. The

Evolion checks every 60 seconds if the maximum charge current is still

exceeded by direct connecting for a short time (see Fast charge mode)

and measuring the current. Regulated charge mode will remain active as

long as the charge current exceeds the maximum allowed charge current.

Discharge is always allowed and switching is done with no time delay.

Fast charge

Charge current is accepted anytime the network voltage is higher than

the Evolion terminal voltage. The cells are directly connected to the

network voltage. If the charge current does not exceed the maximum

allowed charge current (See Charging section), the Fast charge mode

stays active. Anytime the charge current exceeds the maximum allowed

charge current, the Charge regulated mode will become active. Discharge

is always allowed and switching is done with no time delay.

Float charge

Same as Fast charge mode but in this case the network voltage is equal

to the Evolion voltage and the current accepted by the Evolion cells is

zero. The network only provides power (65 mA) for internal electronics.

Discharge is always allowed and switching is done with no time delay.

Forbidden

charge

Regulated charge, fast charge and float charge modes are disabled. This

situation appears when a limit is exceeded, i.e., minimum or maximum

cell or battery voltage. Discharge is always allowed and switching is done

with no delay.

Discharge

Discharge current occurs anytime the network voltage is less than the

Evolion terminal voltage (AC power outage). The battery continues to

discharge until the minimum voltage of 42 V where it switches to the

sleep mode. The battery automatically begins charging, with no switching

delay, when the network voltage (AC power) returns.

Sleep and

Safe

The switch is open. No current can pass in charge or discharge and the

LED’s do not operate. There is no output voltage on the terminals.

4.4 Internal electronic load

An internal electronic load keeps the Evolion’s automatic functionality alive. There are two scenarios, i.e., sleep mode and all other

modes. The low power consumption is supplied from the 48 Vdc circuit.

Sleep mode (OFF) 120 micro-amps @ 42 Vdc

All other operating modes, Nominal (ON) 65 milli-amps @ 56 Vdc