The construction of the Saft

Sunica.plus cell is based upon

the proven Saft pocket plate

technology but with special

features to enhance its use in

the specialised photovoltaic

application.

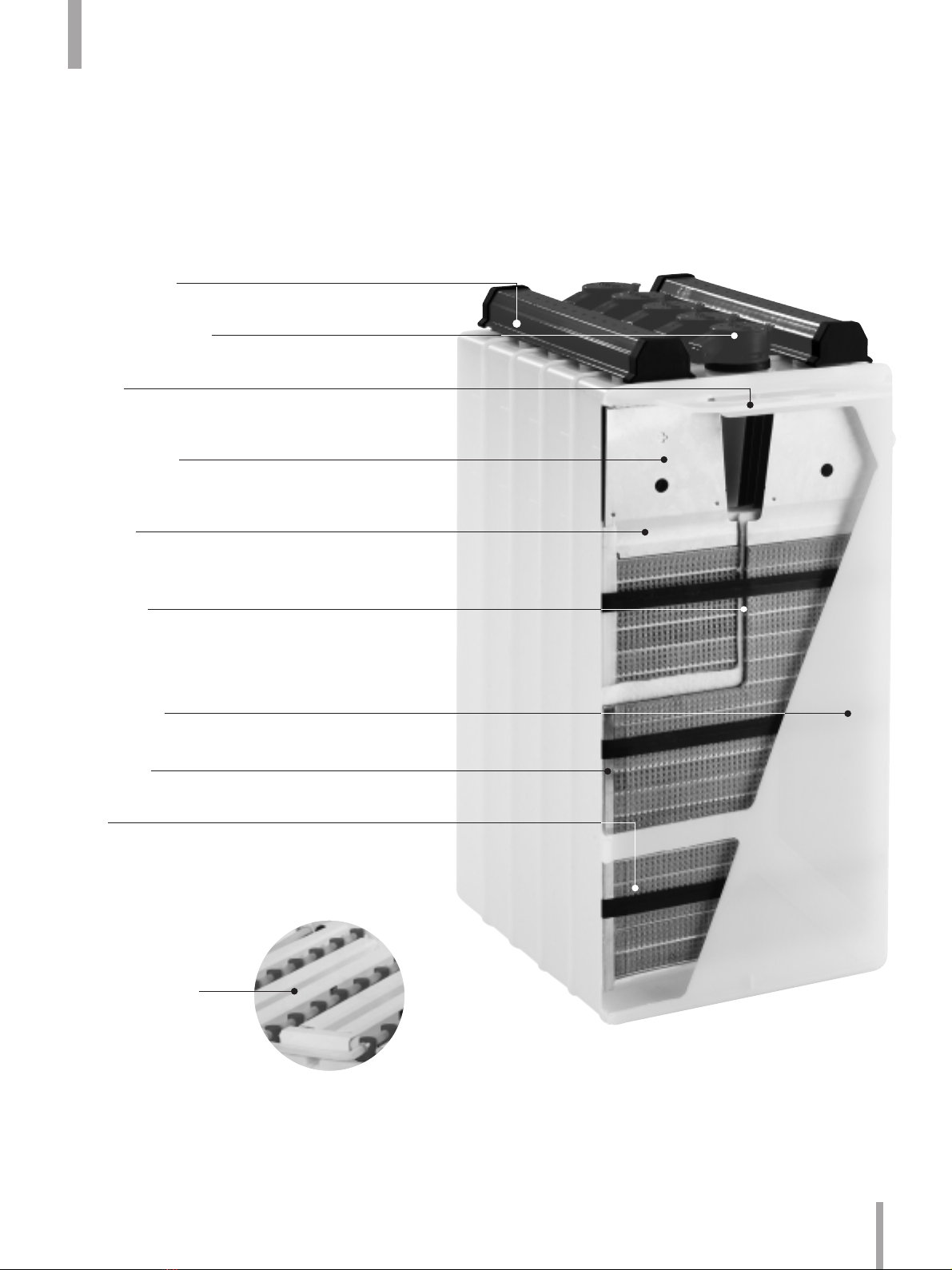

3.1. Plate assembly

The nickel-cadmium cell consists

of two groups of plates, one

containing nickel hydroxide

(the positive plate) and the other

containing cadmium hydroxide

(the negative plate).

The active materials of the Saft

Sunica.plus pocket plate have

been specially developed and

formulated to improve its cycling

ability, a specific need for

photovoltaic applications. These

active materials are retained in

pockets formed from nickel

plated steel which is double

perforated by a patented

process. The pockets are

mechanically linked together, cut

to the size corresponding to the

plate length and compressed to

the final plate dimension. This

process leads to a component

which is not only mechanically

very strong but also retains its

active material within a steel

boundary which promotes

conductivity and minimises

electrode swelling.

These plates are then welded to

a current carrying bus bar

assembly which further ensures

the mechanical and electrical

stability of the product.

Nickel-cadmium batteries have

an exceptionally good cycle life

because their plates are not

gradually weakened by repeated

cycling as the structural

component of the plate is steel.

The active material of the plate

is not structural, only electrical.

The alkaline electrolyte does not

react with steel, which means

that the supporting structure of

the Sunica.plus battery stays

intact and unchanged for the life

of the battery. There is no

corrosion and no risk of “sudden

death”.

In contrast, the lead plate of a

lead acid battery is both the

structure and the active material

and this leads to shedding of the

positive plate material and

eventual structural collapse.

3.2. Separation

The separator is a key feature

of the Sunica.plus battery. It is a

polypropylene fibrous material

which has been used and proven

by Saft in the Ultima ultra-low

maintenance product over more

than 20 years and has been

further developed for this

product to give the features

required. Using this separator,

the distance between the plates

is carefully controlled to give the

necessary gas retention to

provide the level of

recombination required.

By providing a large spacing

between the positive and

negative plates and a generous

quantity of electrolyte between

plates, the possibility of thermal

runaway, a problem with VRLA

cells, is eliminated.

7