6 S&C Instruction Sheet 663-500

Safety Precautions

DANGER

S&C Source-Transfer PMH Pad-Mounted Gear operates at high-voltage.

Failure to observe the precautions below will result in serious personal injury

or death.

Some of these precautions may differ from company operating procedures and rules.

Where a discrepancy exists, follow your company’s operating procedures and rules.

1. QUALIFIED PERSONS. Access to S&C Source-

Transfer PMH Pad-Mounted Gear must be restricted

only to qualified persons. See the “Qualified Persons”

section on page 2.

2. SAFETY PROCEDURES. Always follow safe

operating procedures and rules.

3. PERSONAL PROTECTIVE EQUIPMENT. Always

use suitable protective equipment, such as rubber

gloves, rubber mats, hard hats, safety glasses, and

flash clothing, in accordance with safe operating

procedures and rules.

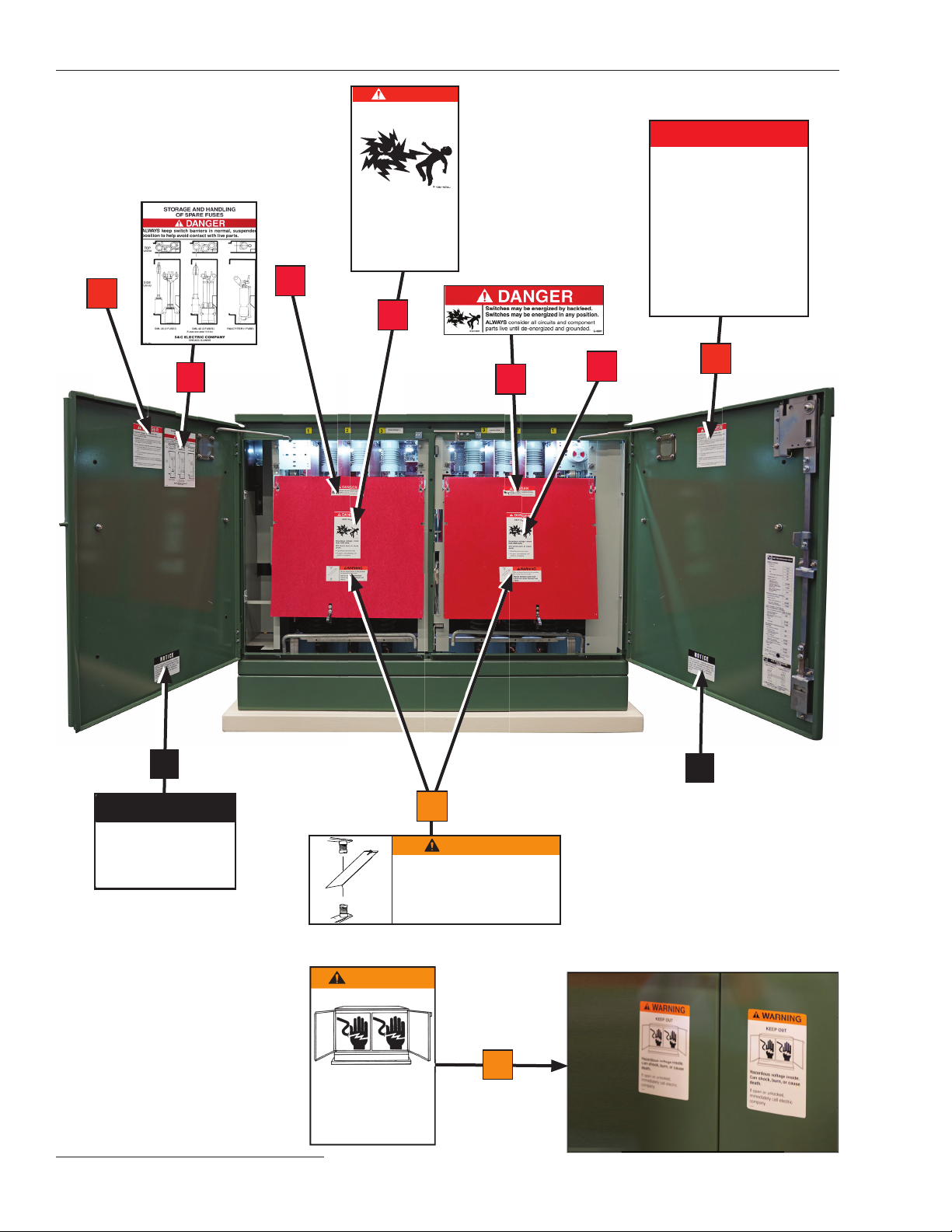

4. SAFETY LABELS. Do not remove or obscure any of

the “DANGER,” “WARNING,” “CAUTION,” or

“NOTICE” labels.

5. HIGH-VOLTAGE ISOLATION. Switch operators and

controls are isolated from high voltage in grounded,

metal-enclosed compartments. Access to these

components is controlled by padlockable covers,

which incorporate a nonremovable manual handle.

Other low-voltage components, such as meters,

selector switches, toggle switches, etc., are similarly

isolated.

6. TEST FOR VOLTAGE. Test for voltage using proper

high-voltage test equipment before touching any

device to be inspected, serviced, or repaired in the

high-voltage compartments.

7. ENERGIZED COMPONENTS. Always consider all

parts live until de-energized, tested, and grounded.

Voltage levels can be as high as the peak line-to-

ground voltage last applied to the unit. Units energized

or installed near energized lines should be considered

live until tested and grounded.

8. GROUNDING.

• Make sure the pad-mounted gear enclosure is

properly grounded to the station or facility ground.

• After the gear has been completely disconnected

from all sources of power and tested for voltage,

install suitable grounding cables in all compartments

before touching any device that is to be inspected,

replaced, serviced, or repaired in the high-voltage

compartments.

9. MAINTAINING PROPER CLEARANCE. Always

maintain proper clearance from energized

components.

10. SWITCH POSITION.

• Always confirm the Open/Close position of Mini-

Rupter® Switches by visually observing the position

of the switch blades.

• Switches may be energized by backfeed.

• Switches may be energized in any position.

11. PADLOCKS. Non-removable, manual handles in

high-voltage compartment doors and hinged-

padlockable covers, as well as hinged-bolted panels,

have provisions for padlocks that must be in place and

secured at all times unless work is being

performed inside the enclosure. Padlocks must be

installed and secured on manual switch operating

handles at alltimesunless theswitchis being operated.

12. KEY INTERLOCKS. Key interlocks (if applicable)

must be in place. Check the operating sequence of

key interlocks to verify proper sequencing. After the

switchgear is installed, destroy all duplicate keys or

make them accessible only to authorized persons so

the key interlock scheme will not be compromised.

Key interlocks are not security locks.

13. MECHANICAL CABLE INTERLOCKS. Mechanical

cable interlocks are provided to prevent access to

fuses unless the switch is open and to prevent

operation of stored-energy switch operators when the

enclosure door is open. Do not attempt to operate any

switch when the enclosure door is open. Periodically,

verify these interlocks are functional.

14. DO NOT APPLY UNDUE FORCE. Do not apply any

undue force when attempting to open a door. The use

of undue force may damage the door-latching

mechanism. If optional key interlocks are provided,

make certain the interlocks are in their correct

positions to allow door opening.

15. FUSE HANDLING.

• Make certain fuses are disconnected from all power

sources (including backfeed) before being inspected

or replaced.

• Always store fuses in a clean, dry location.

• Do not store end-fittings, holders, interrupting

modules, or fuses in termination compartments

unless the unit is equipped with the optional fuse-

storage feature (catalog number suffix “-E1,” “-E2,”

or “-E3”).

16. BACKFEED. Mini-Rupter Switches and fuses may be

energized by backfeed.