June 1, 2021

© S&C Electric Company 2021, all rights reserved Instruction Sheet 461-519

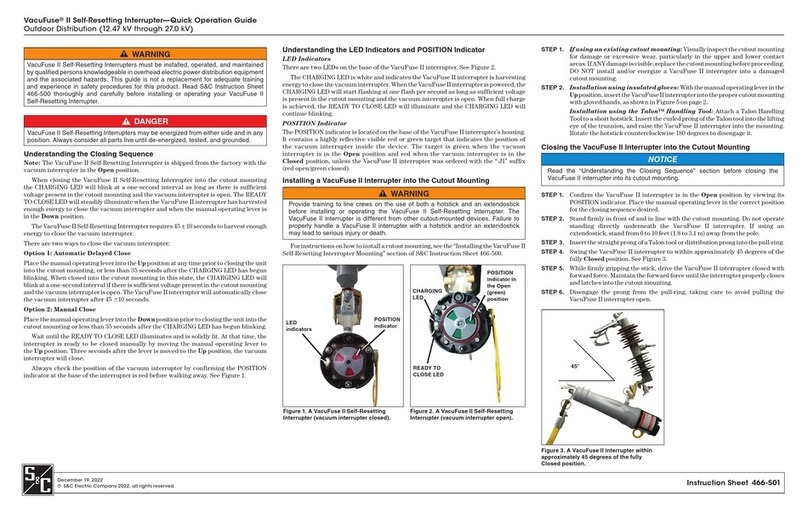

TripSaver®II Cutout-Mounted Recloser

Outdoor Distribution (15.5 kV, 25 kV)

TripSaver®II Communications via Gateway

using the IEC 60870-5-104 Protocol

Installation, Operation, and Conguration

Table of Contents

Section Page Section Page

Introduction

Qualified Persons ........................... 2

Read this Instruction Sheet ................... 2

Retain this Instruction Sheet. . . . . . . . . . . . . . . . . . . 2

Video..................................... 2

Proper Application .......................... 2

Warranty .................................. 2

Safety Information

Understanding Safety-Alert Messages........... 3

Following Safety Instructions .................. 3

Replacement Instructions and Labels ........... 3

Location of Safety Labels ..................... 4

Safety Precautions ......................... 5

Shipping and Handling

Packing ................................... 6

Inspection ................................. 6

Handling .................................. 6

Storage ................................... 6

Returning ................................. 6

Mounting, Powering, and Securing the

Communications Gateway................... 7

Mounting the Communications Gateway to a Pole.. 8

Powering the Communications Gateway ......... 9

Securing the Communications Gateway ......... 9

Installing and Replacing a Radio

Installing a New Radio .......................10

Replacing a Radio ..........................11

Installing and Replacing a Backup Battery

Installing a New Battery ......................12

Replacing a Battery .........................13

Installing Remote Antenna Kits

Installing Remote Antenna Kit 903-002702-02/01 ..14

Installing Remote Antenna Kit 903-002701-01/02 ..15

Installing Remote Antenna Kit 903-002700-02/03 ..15

Installing and Replacing a Local Antenna

Installing Local Antenna 904-002450-02 .........16

Replacing a Local Antenna....................16

Configuring the Communications Gateway

Software User’s Guide .......................17

Enabling IEC 60870-5-104 Communication

Protocol in the Communications Gateway ......19

General Status ............................ 20

Gateway Settings ...........................21

Device Management........................ 37

Tri pSaver ®II Service Center Configuration

Software ................................. 38

Remote Drop Open......................... 40

Gang/Local Operation ...................... 42

User Roles ............................... 46

IEC 104 Setpoints ...........................47

IEC104 Controlling Station ................... 53

IEC104 Controlled Station ................... 53

Security Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Profile ................................... 58

Diagnostics ............................... 58

Commissioning (Pairing) a TripSaver II Recloser

for Use with the Communications Gateway

Service Center Pairing a TripSaver II Recloser

with Firmware Version 1.9 or 1.8 ............ 60

Field Pairing a TripSaver II Recloser with Firmware

Version 1.6 or 1.7 Installed on the Utility Pole

and Powered by Line Current................61

Troubleshooting

Signal Interference ......................... 63

Pairing Process Takes Longer Than Expected ... 63

Quick Installation Checklist ................ 64

Appendix A

Interface Pinouts........................... 65

Power System Diagram ..................... 66

Understanding the Radio Mode ............... 66

Appendix B

Regulatory Information..................... 68