6 S&C Instruction Sheet 682-510

DANGER

Vista Underground Distribution Switchgear contains high voltage� Failure to

observe the precautions below will result in serious injury or death�

Some of these precautions may differ from company operating procedures and

rules� Where a discrepancy exists, users should follow their company’s operating

procedures and rules�

1�

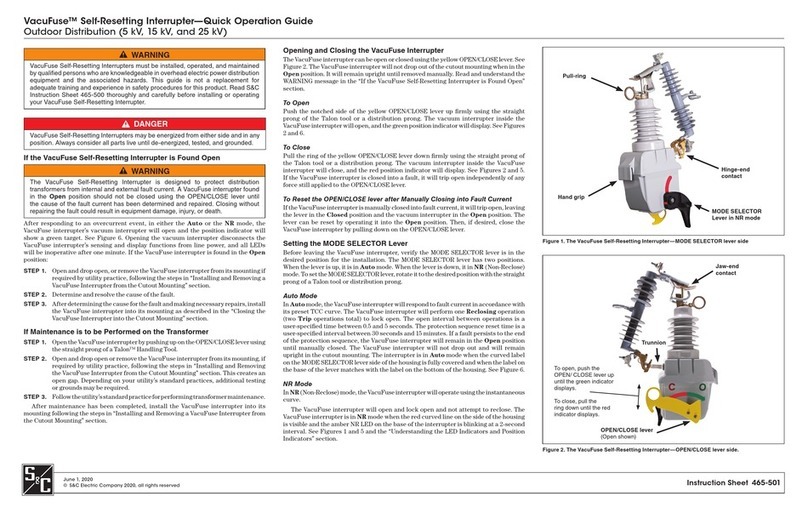

QUALIFIED PERSONS� Access to Vista Underground

Distribution Switchgear must be restricted only to

qualified persons� See the “Qualified Persons” section

on page 2�

2�

SAFETY PROCEDURES� Always follow safe

operat ing procedures and rules�

3�

PERSONAL PROTECTIVE EQUIPMENT� Always

use suitable protective equipment, such as rubber

gloves, rubber mats, hard hats, safety glasses, and

flash clothing, in accordance with safe operating

procedures and rules�

4�

SAFETY LABELS� Do not remove or obscure any of

the “CAUTION,” “WARNING,” or “DANGER” labels�

5�

CLOSING AND LOCKING ENCLOSURES� The

pad-mounted enclosure and low-voltage compartment

or enclosure must be securely closed with padlocks

in place at all times unless work is being performed

inside�

6�

ENERGIZED BUSHINGS� Always assume the

bushings are energized unless proven otherwise by

test, by visual evidence of an open-circuit condition

at the load-interrupter switch or fault interrupter, or

by observing that the load-interrupter switch or fault

interrupter is grounded�

7�

BACKFEED� Bushings, cables, load-interrupter

switches, and fault interrupters may be energized

by backfeed�

8� DE-ENERGIZING, TESTING, AND GROUNDING�

Before touching any bushings or components inside

the switchgear that are to be inspected, replaced,

serviced, or repaired, always disconnect load-

inter rupter switches and fault interrupters from all

power sources (including backfeed), test for voltage,

and properly ground�

9�

TESTING� Test the bushings for voltage using the

Voltage Indication feature (if furnished) or other

proper high-voltage test equipment before touching

any bushings or components inside the switchgear

that are to be inspected, replaced, serviced, or

repaired�

10� GROUNDING�

•

Make sure the switchgear tank and pad-mounted

enclosure are properly grounded to the station

or facility ground� Improper grounding will cause

equipment damage�

•

After the switchgear has been completely

discon nected from all sources of power and tested

for voltage, properly ground the load-interrupter

switches and fault interrupters before touching any

bushings or components inside the switchgear

that are to be inspected, replaced, serviced, or

repaired�

11�

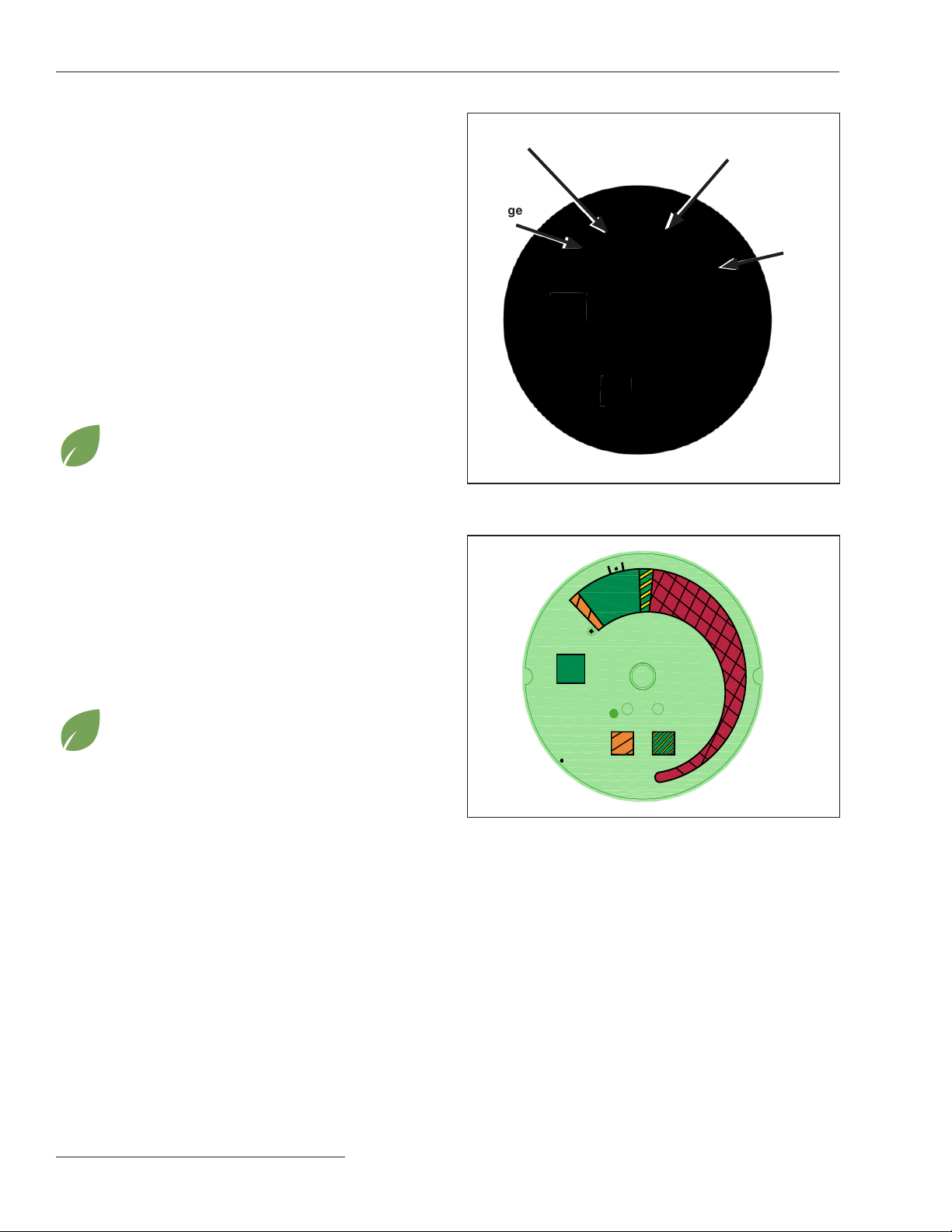

LOAD-INTERRUPTER SWITCH AND FAULT-

INTERRUPTER POSITION�

•

Always confirm the Closed/Open/Grounded

position of load-interrupter switches and fault

interrupters by visually observing the position of

the blades�

•

Load-interrupter switches and fault interrupters

may be energized by backfeed�

•

Load-interrupter switches and fault interrupters

may be energized in any position�

12�

MAINTAINING PROPER CLEARANCE� Always

maintain a proper clearance from energized

bushings�

Safety Precautions