2S&C Instruction Sheet 665-506

Introduction

Qualified Persons ÇWARNING

The equipment covered by this publication must be installed, operated, and

maintained by qualified persons who are knowledgeable in the installation, operation,

and maintenance of overhead electric power distribution equipment along with the

associated hazards. A qualified person is one who is trained and competent in:

The skills and techniques necessary to distinguish exposed live parts from non-•

live parts of electrical equipment.

The skills and techniques necessary to determine the proper approach distances•

corresponding to the voltages to which the qualified person will be exposed.

The proper use of the special precautionary techniques, personal protective•

equipment, insulating and shielding materials, and insulated tools for working

on or near exposed energized parts of electrical equipment.

These instructions are intended only for such qualified persons. They are not

intended to be a substitute for adequate training and experience in safety procedures

for this type of equipment.

Read this

Instruction Sheet

Read this instruction sheet thoroughly and carefully before installing or operating

your S&C Manual PME Pad-Mounted Gear. Familiarize yourself with “Safety Information”

on page 4.

Retain this

Instruction Sheet

This instruction sheet is a permanent part of your S&C Manual PME Pad-Mounted Gear.

These instructions should be stored in the low-voltage connection enclosure, using the

instruction manual holder.

Proper Application ÇCAUTION

The equipment in this publication is only intended for a specific application. The

application must be within the ratings furnished for the equipment. Ratings for this

gear are listed on the ratings label on the interior of the doors (right-hand door only

for double-door models.)

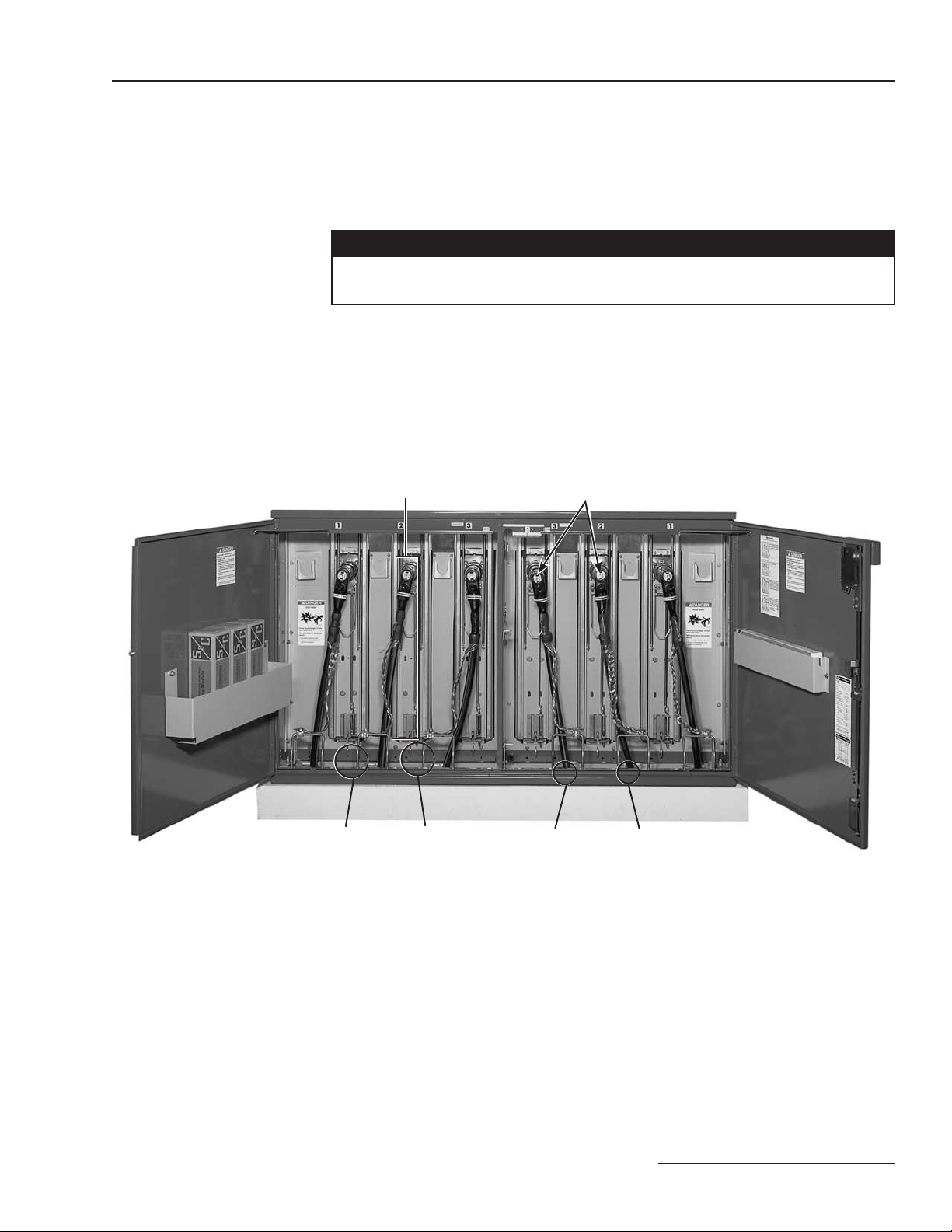

General The following instructions cover installation of arc-resistant models of S&C Manual PME

Pad-Mounted Gear which features elbow-connected encased components and is available

in ratings of 14.4 kV and 25 kV. Switch terminals are equipped with 600-ampere-rated

bushings and fuse terminals are equipped with 200-ampere-rated bushing wells. Bushing

and bushing-well interfaces are in accordance with ANSI/IEEE Standard 386 to accept

all standard separable insulated connectors and inserts. Parking stands are provided

adjacent to each bushing and bushing well.

Refer to S&C Instruction Sheet 665-610 for instructions regarding operation of Manual

PME Pad-Mounted Gear. The instruction sheets, along with a catalog dimensional drawing

showing cable-locating and anchor-bolt dimensions, are included in the “Installation and

Operation Information Kit” provided with the gear. Wiring diagrams for the gear and

associated options are also provided in the kit. All personnel involved with the installation

and operation of the equipment should be thoroughly familiar with the contents of the

information kit.

The catalog number stamped on the nameplates affixed to the outside of the doors

of the pad-mounted gear is suffixed with letter-number combinations. These suffixes

indicate the inclusion of optional features, such as key interlocks (Catalog Number Suf-

fix “-C1”, “-C3”, or “-C4”). Refer to “OPTIONAL FEATURES” on page 16 for a complete

listing of the available options for the gear.