Revision 02/24/2022 document 630-1057

Lock setup

Interface with Bolt work:

The 6120/6123 lock is not intended for direct bolt work attachment. Before

installing the lock, operate the safe opening mechanism and verify that the

installed position willeffectively secure the bolt works when the lock is locked. After

installation, check that there is clearance between the combination lock bolt and the

bolt works; as pressure onthe bolt could affect the lock’s ability to function properly.

Attaching Screws:

Use only the screws provided with the lock. They must engage the mounting plate by at

least four full threads. Do not use lock washers or thread sealing compounds.

Recommended Attaching Screw Torque:

30 to 40 inch-pounds (33.9 to 45.2 dNm) for the lock body. No more than 15 inch-pounds

(1.695 Nm) for the keypad base attaching screws.

Minimum Lock Cable (Spindle) Hole Diameter:

0.312 inch (7.9 mm)

1.624" (41,2mm)

Maximum Lock Cable (Spindle) Hole Diameter:

0.406 inch (10.3 mm)

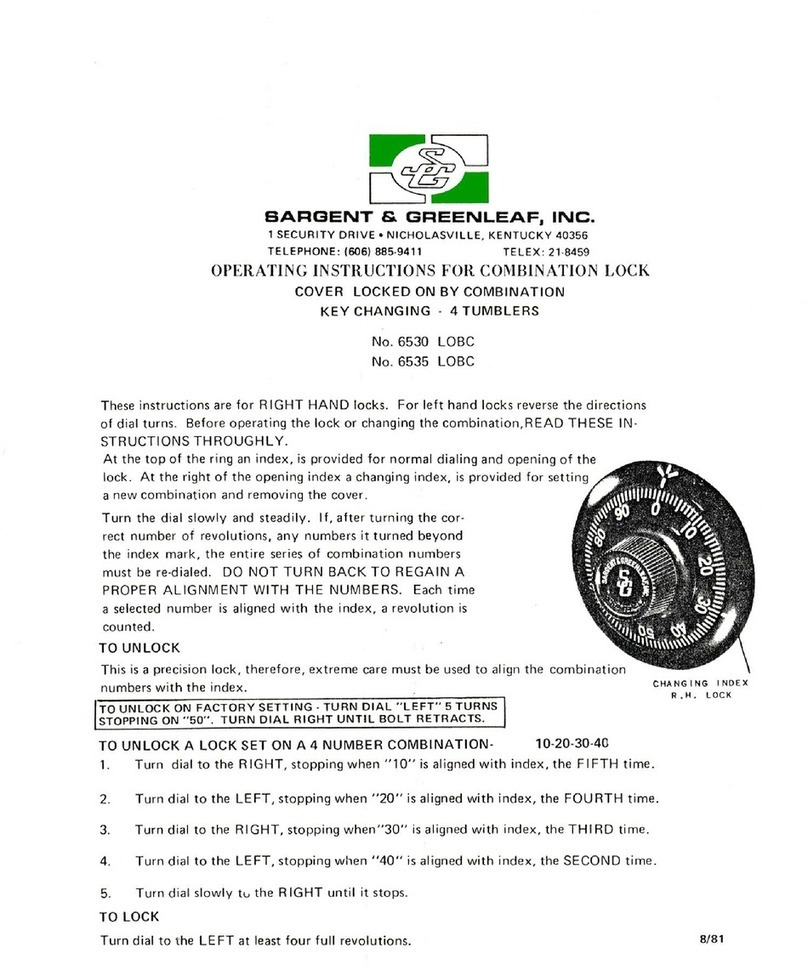

Lock is designed to Move:

50 Grams (.49 N)

Lock Bolt Maximum Free Movement:

0.352 inch (8.95 mm) / 0.109 inch outside the edge of the lock case

Maximum Bolt End Pressure:

lock is designed to withstand at least 225 lbs. (1000 Newtons)

Maximum Bolt Side Pressure:

Safe and container boltwork or locking cam designs must never apply more than 225

lbs. (1000 Newtons) of side pressure on the lock bolt.

Mounting Environment:

The lock body is designed to be mounted inside a secure container. The container must

be constructed to offer protection against physical attack directed at the lock. The

amount of protection is dependent on the desired level of security for the system as a

whole. Lock protection may include barrier materials, relock devices, thermal barriers,

thermal relock components, or any combination of these. Relock device attaching

screws must NOT be longer than the depth of the tapped hole provided in the lock case.

Security relevant parts of a high security lock should not be accessible to unauthorized

persons when the door of the secure storage unit to which it is fitted is open. A

minimum distance of 0.150 inch (3.8 mm) is recommended between the end of the lock

case and the closest approach of the safe’s blocking bar or cam plate (which is normally

blocked by the extended lock bolt). Maintaining this clearance will allow the lock to

deliver optimum performance.

Code Restrictions:

Personal data that can be related to a code holder, such as a birth date, street number,

or phone number, should not be used in creating a lock code. Avoid codes that can be

easily guessed (such as 12345678 or 11111111). The lock’s factory default codes should be

changed when the lock is put into operation by the end user.

1.000" (25,4mm)

Bolt extension:

Locked = .461"

(11,71mm)

Unlocked = .125"

(3,18mm)

.312"

7,9mm

.281"

7,1mm

Note:

Every installation of this product must comply with these requirements and those in the product installation instructions to qualify for the

manufacturer’s warranty and to comply with EN1300 requirements. The length of any external cabling used for this product must not exceed 3

meters in length. Use of cabling exceeding 3 meters may void product certifications.

Corporate Headquarters: One Security Drive

|

Nicholasville, Kentucky 40356

|

1-800-826-7652 . Except as otherwise noted, all trademarks in this data sheet are

trademarks of Sargent and Greenleaf in the U.S. and elsewhere. ®denotes a trademark registered with the U.S. Patent and Trademark Office and/or other Trademark

offices around the world.

3.320" (84,3mm)

2.624" (66,6mm)