- 10 -

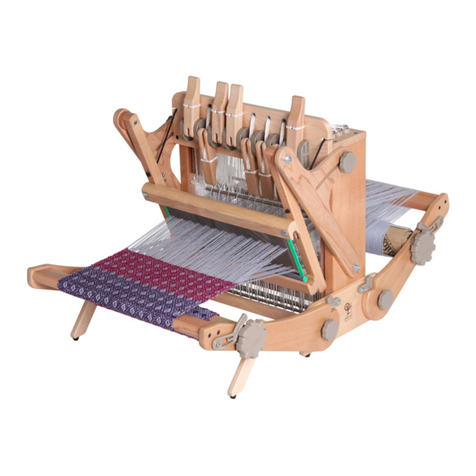

11. Install the jacks and lamms.

Parts: jack assemblies listed below for your loom

Hardware Bag D: hardware listed below for your loom

4-shaft looms: 2X 3-1/2" jack pivot rods, 14X 3/8" SAE washers,

2X #1 jack assemblies, 2X #3 jack assemblies

8-shaft looms: 2X 6-1/2" jack pivot rods, 22X 3/8" SAE washers,

2X #1 jack assemblies, 2X #2 jack assemblies, 2X #3 jack

assemblies, 2X #4 jack assemblies

4 Now-4 Later looms: 2X 6-1/2" jack pivot rods, 14X 3/8" SAE

washers, 2X #1 jack assemblies, 2X #2 jack assemblies, 6X 3/4"

nylon spacers

All looms: From the rear of the loom, insert the jack pivot rods

into the larger holes of the front castle cross brace. Place two 3/8"

SAE washers on each of the rods (Figure 11A).

4-shaft Looms: Place a #1 jack assembly on the jack pivot rods,

followed by a 3/8" SAE washer on each rod (Figure 11B). Place

the second #1 jack assembly on the jack pivot rods, followed by

3/8" SAE washer on each rod. Place a #3 jack assembly on the

jack pivot rods, followed by another 3/8" SAE washer on each

rod. Place the second #3 jack assembly on the jack pivot rods, and

nish with two more 3/8" SAE washers on each rod (Figure 11C).

8-shaft looms: Place a #1 jack assembly on the jack pivot rods,

followed by a 3/8" SAE washer on each rod (Figure 11B). Place

the second #1 jack assembly on the jack pivot rods, followed by

3/8" SAE washer on each rod. Place a #2 jack assembly on the

jack pivot rods, followed by another 3/8" SAE washer on each

rod. Place the second #2 jack assembly on the jack pivot rods,

followed by another 3/8" SAE washer on each rod. Continue with

a #3 jack assembly, a 3/8" SAE washer on each rod, the second

#3 jack assembly, a 3/8" SAE washer on each rod, a #4 jack

assembly, a 3/8" SAE washer on each rod, and the second #4 jack

assembly. Finish by placing two more 3/8" SAE washers on each

rod (Figure 11C).

4 Now-4 Later looms: Place a #1 jack assembly on the jack pivot

rods, followed by a 3/8" SAE washer on each rod (Figure 11B).

Place the second #1 jack assembly on the jack pivot rods, followed

by 3/8" SAE washer on each rod. Place a #2 jack assembly on the

pivot rods, followed by another 3/8" SAE washer on each rod.

Place the second #2 jack assembly on the jack pivot rods, followed

by another 3/8" SAE washer on each rod. Finish by placing two

more 3/8" SAE washers on each rod (Figure 11C), followed by

three nylon jack spacers on each rod.

12. Install the rear castle cross brace.

Parts: rear castle cross brace

Hardware Bag D: 4X #8 x 1-1/2" Phillips truss head sheet metal

screws

Place the rear castle cross brace behind the jacks so that the jack

pivot rods t into their holes—these holes do not go all the way

through the brace (Figure 12). Using two #8 x 1-1/2" Phillips

truss head sheet metal screws at each end, attach the rear castle

cross brace to the castle.

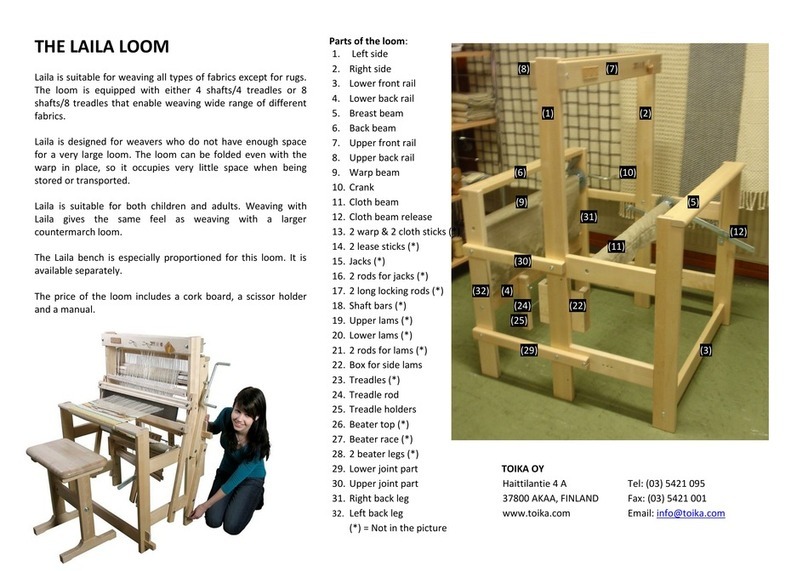

FIGURE 11: INSTALL THE JACK ASSEMBLIES

A

back side of

front castle

cross brace

jack pivot rods,

with two washers

on each rod

C

two washers on

each rod

all jack

assemblies

B

#1 jack assembly

one washer

on each rod

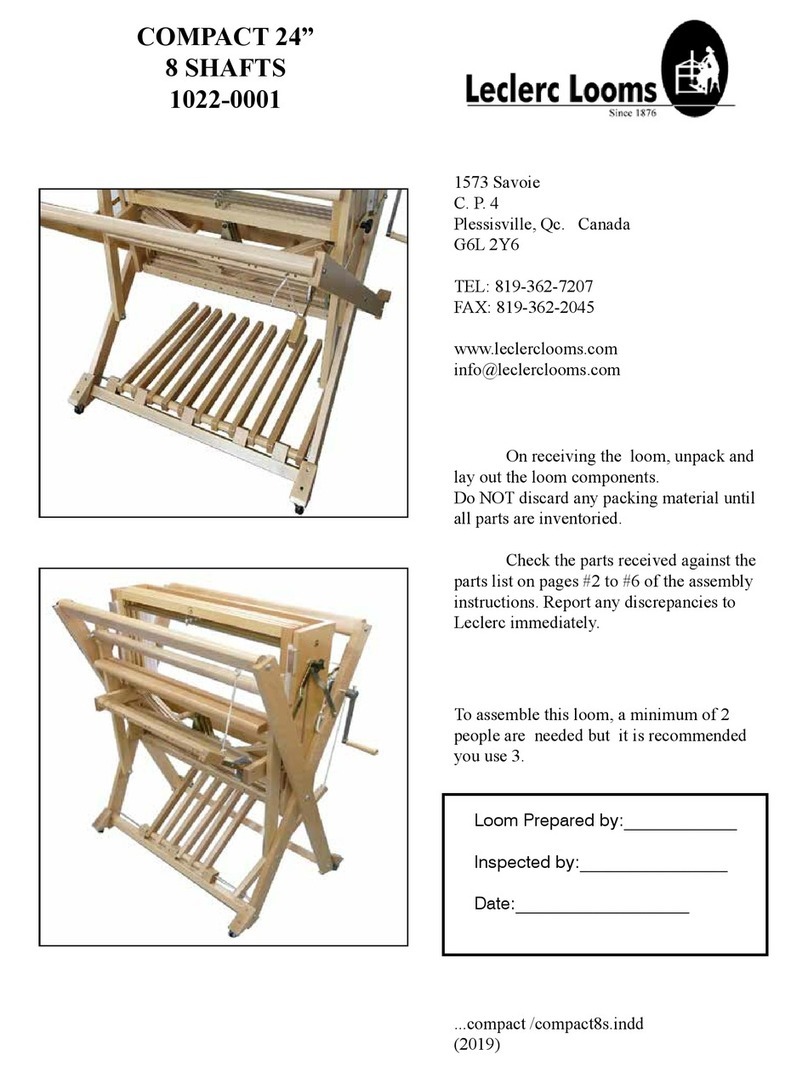

FIGURE 12: INSTALL THE REAR CASTLE CROSS BRACE

rear castle

cross brace

#8 x 1-1/2" Phillips truss

head sheet metal screws

#8 x 1-1/2" Phillips truss

head sheet metal screws