– 5 –

TIE-UP CORDS

There is one tie-up cord for every

lamm hole. On the 8.10 the 2 outer holes

have metal spring pins inserted that work

as jack pins holding the shaft assembly

together. Thread the tie up-cord through

the spring pins the same as you would in

the other 8 holes in the lamm.

Thread the loop of one end of each

tie-up cord through a hole in the lamm

and pull the button end through the loop

until the cord is secure against the lamm.

Attach the shafts to the treadle by slipping

a tie-up cord into the slot in the treadle.

Work from the front lamm to the rear

lamm for each treadle. After completing

your tie-up, check each treadle by push-

ing it all the way to the floor and releas-

ing it, making sure that the knob of each

tie-up cord is against the treadle and that

each cord hangs straight down.

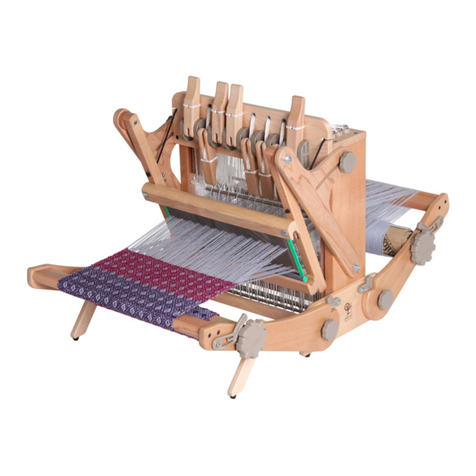

INSTALLING THE HEDDLES

Remove the shafts from the loom by

removing the rubber rings and unscrew-

ing the small hex nuts from the jack

pins. Pull a shaft straight up and out of

the loom. When you put the shaft back

in the loom, be sure to insert the jack

pin back into the hole and secure it with

the hex nut. Replacing the rubber ring is

optional.

Lay a shaft on a flat surface. Lay

two heddle bars next to the heddles.

Carefully slide a group of heddles onto

the heddle bars. Fit one end of each

heddle bar into one of the slots in the

shaft frame. Using very gentle pressure,

flex the heddle bar just enough to fit the

other end into the slot on the opposing

side of the shaft. Separate approximately

half of the heddles to each end of the

shaft. Put the shaft back in the loom,

and secure the jack pin with the hex nut.

Repeat for the other shafts. Be sure to

keep the heddles oriented in the same

direction for easier threading.

jack

pin

hex nut

rubber

O-ring

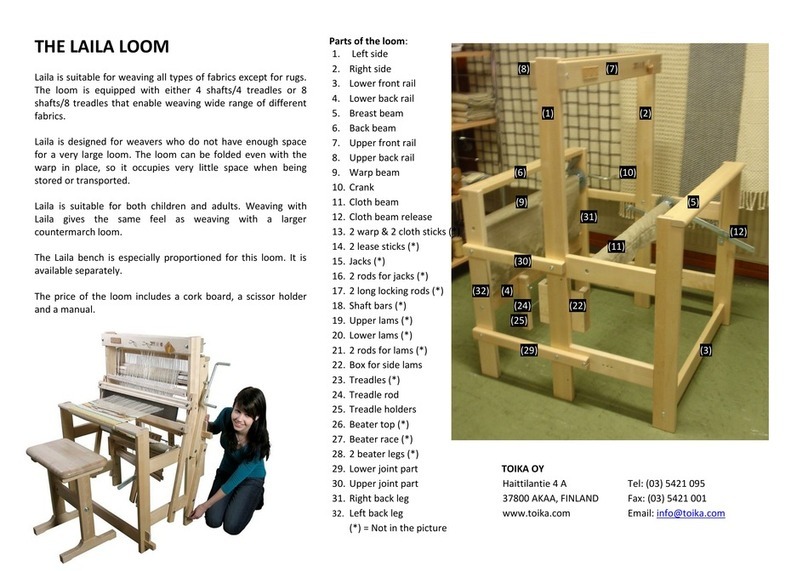

JACK PINS

shaft

frame

rear cross

brace

shaft heddle bar

heddle

bar

heddles

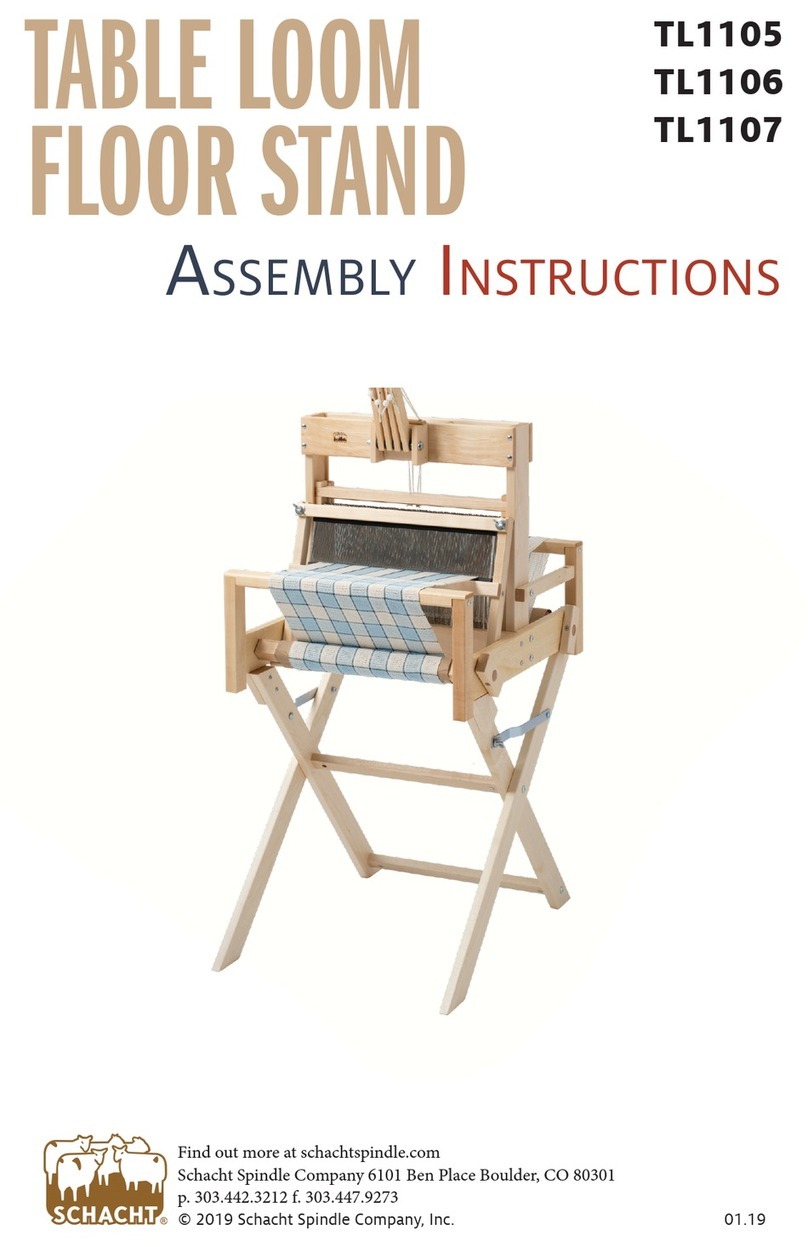

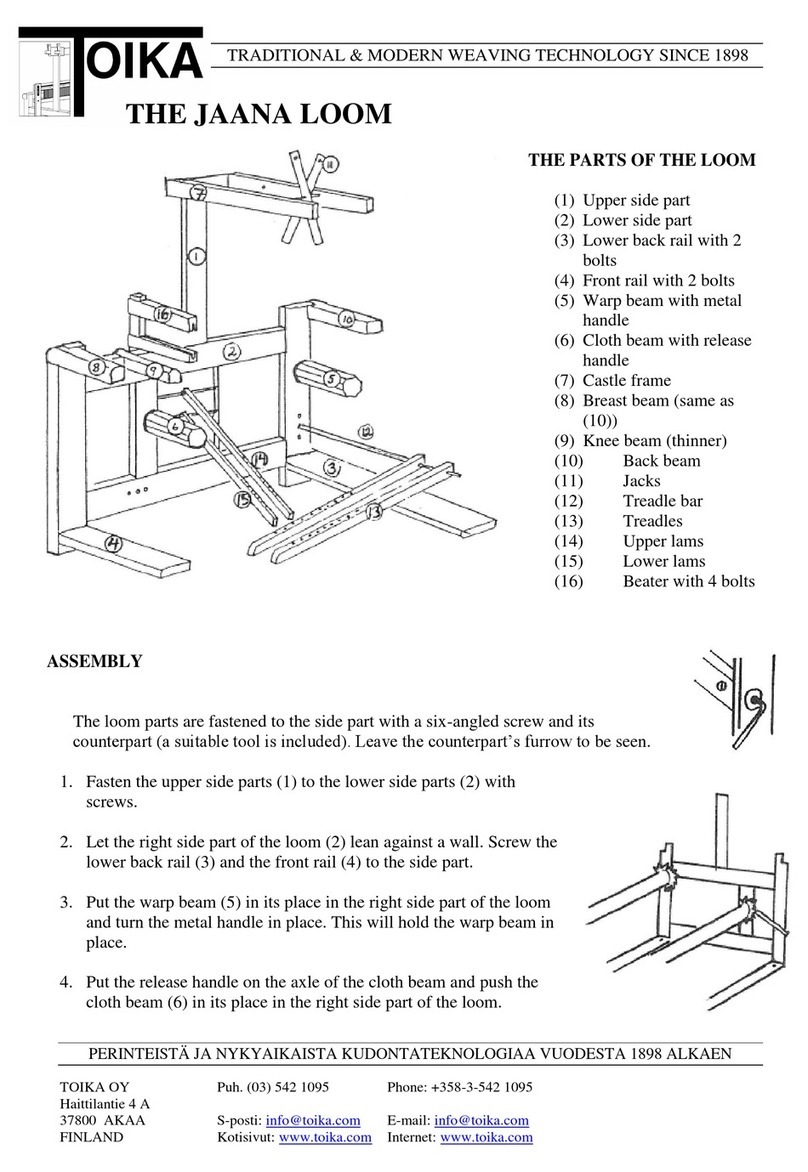

TREADLES AND JACK AND LAMM ASSEMBLY

(REAR VIEW)

lamm

jack

riser

tie-up

inner treadles outer treadles

jack