Schacht Wolf Pup User manual

Other Schacht Weaving manuals

Schacht

Schacht Wolf Pup Installation guide

Schacht

Schacht Wolf Pup User manual

Schacht

Schacht WOLF PUP & PUP LT User manual

Schacht

Schacht CRICKET LOOM User manual

Schacht

Schacht BABY WOLF FL3001 User manual

Schacht

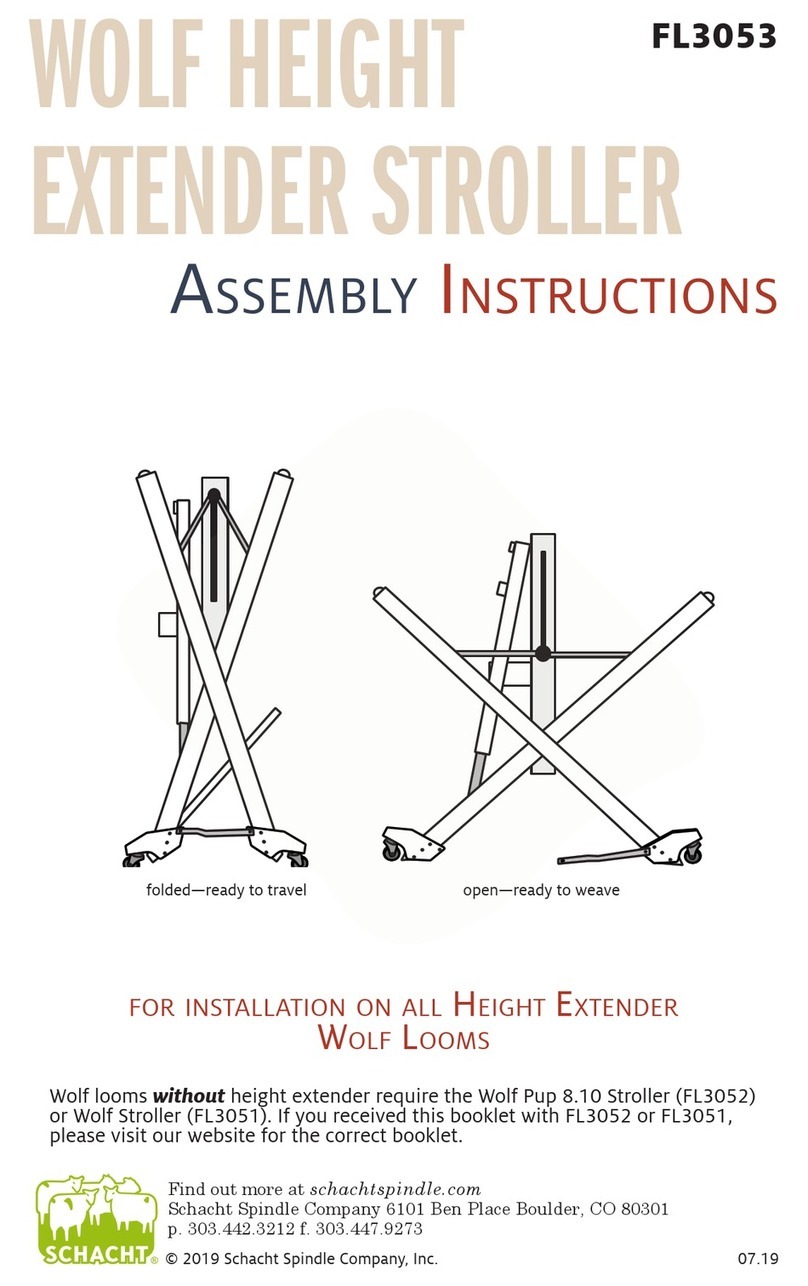

Schacht FL3053 User manual

Schacht

Schacht CRICKET QUARTET SL2045-05 User manual

Schacht

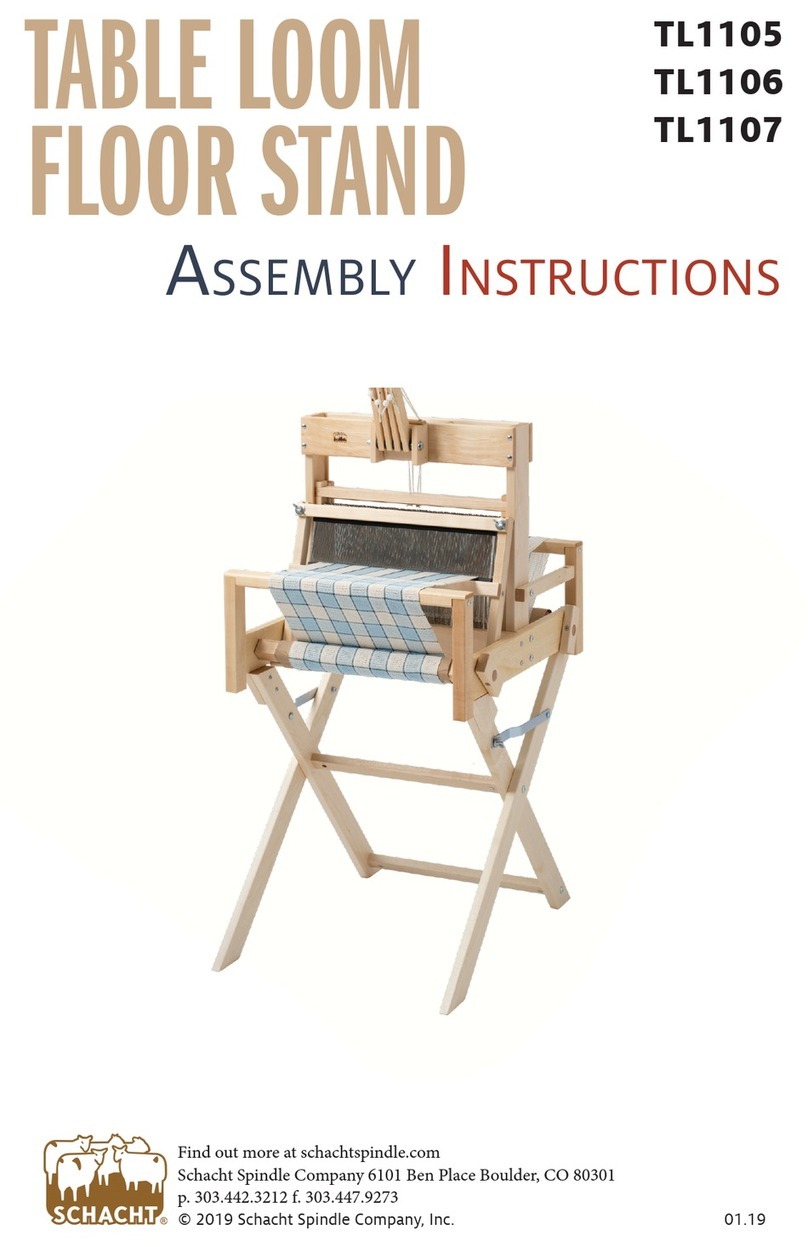

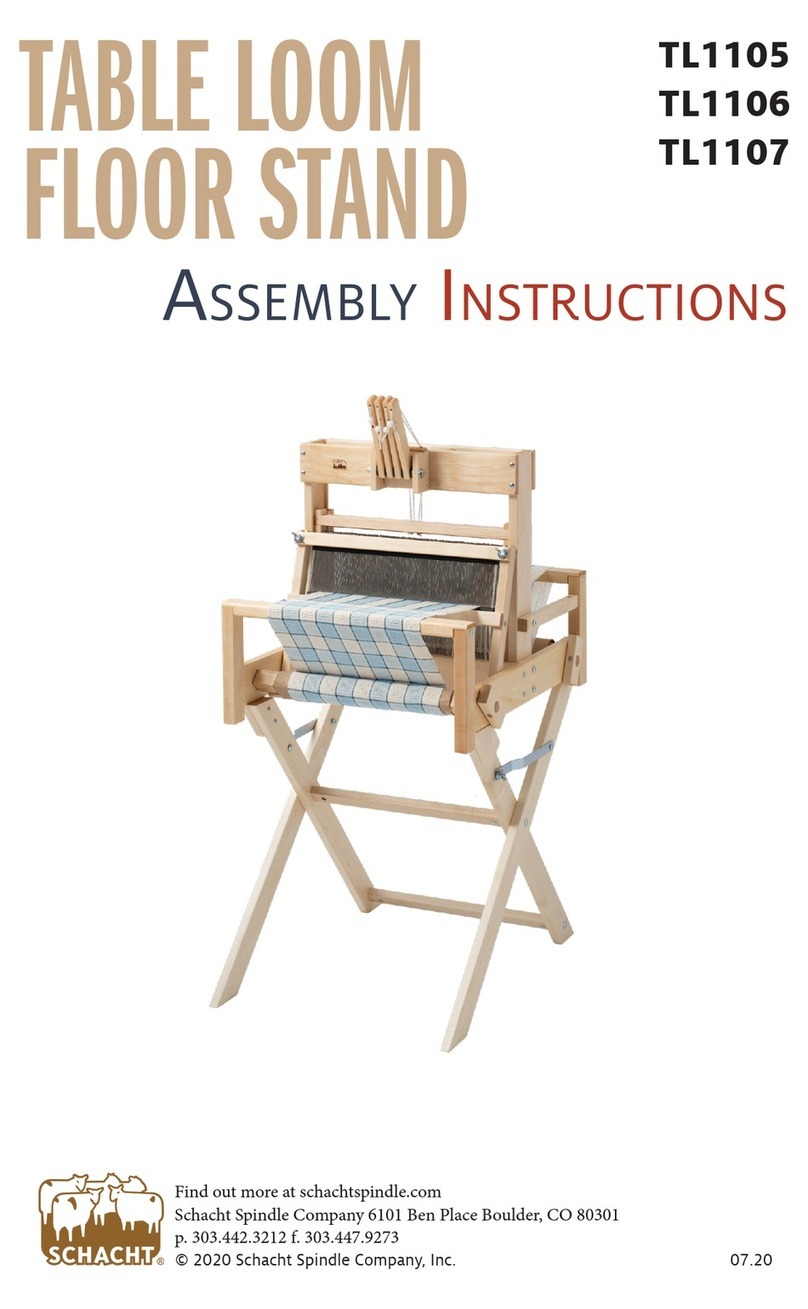

Schacht TL1105 User manual

Schacht

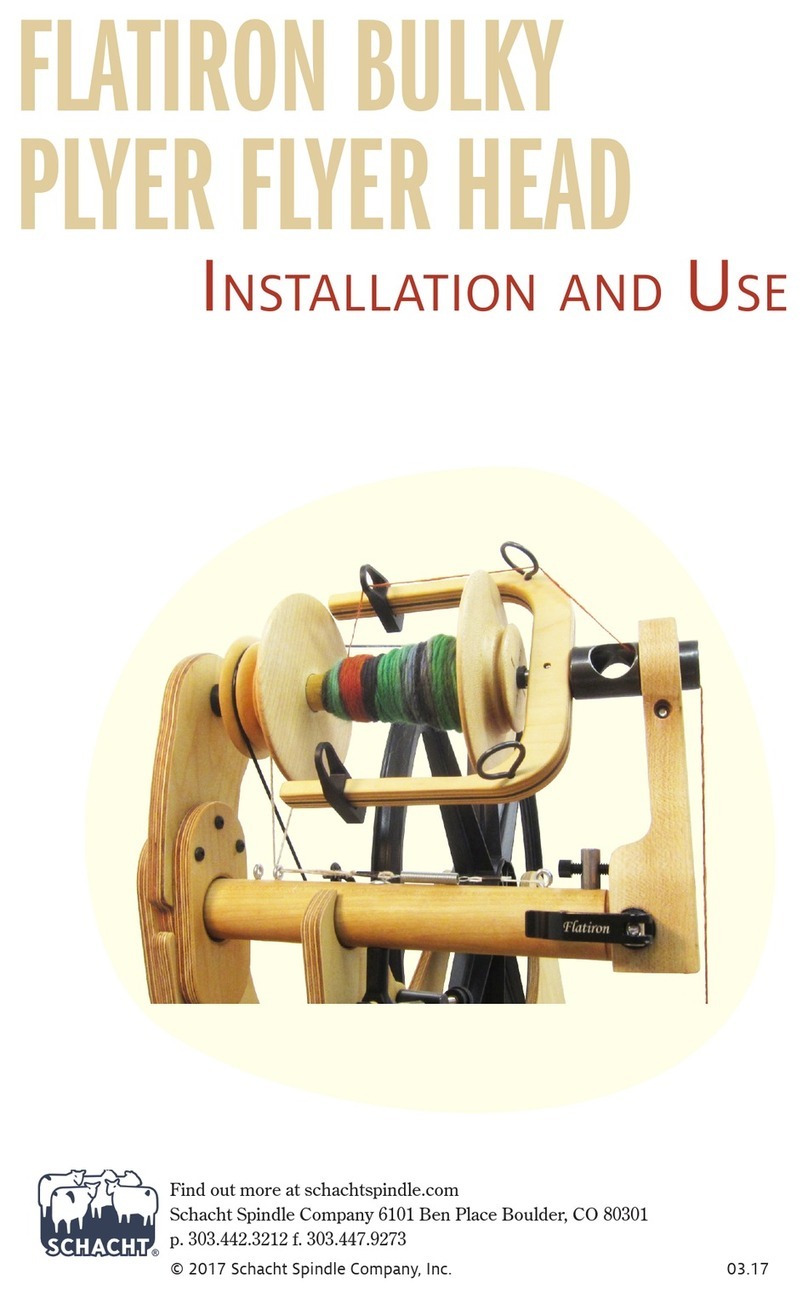

Schacht FLATIRON BULKY PLYER FLYER HEAD Quick start guide

Schacht

Schacht Wolf Pup User manual

Schacht

Schacht WOLF PUP 8.10 LOOM User manual

Schacht

Schacht Wolf Pup 8.10 User manual

Schacht

Schacht WOLF PUP 8.10 STROLLER User manual

Schacht

Schacht MIGHTY WOLF FL3002E User manual

Schacht

Schacht FL3109 User manual

Schacht

Schacht CRANBROOK User manual

Schacht

Schacht TABLE LOOM User manual

Schacht

Schacht CRANBROOK LOOM User manual

Schacht

Schacht WOLF SECTIONAL BEAM User manual

Schacht

Schacht SL2225 User manual