Table of Contents

Table of Contents

1 General.................................................................................................................... 5

1.1 Warnings .............................................................................................................. 5

1.2 Applicable documents .......................................................................................... 6

2 Basic safety instructions........................................................................................... 7

2.1 Intended use......................................................................................................... 7

2.2 Not intended use.................................................................................................. 7

2.3 Notes on particular risks....................................................................................... 8

2.4 Notes on safe operation ..................................................................................... 10

2.4.1 Substantial modifications .......................................................................13

2.5 Personnel qualification....................................................................................... 13

2.6 Organizational measures.................................................................................... 13

2.7 Using personal protective equipment ................................................................14

3 Warranty ................................................................................................................15

4 Torques per screw ..................................................................................................16

5 Scope of Delivery ....................................................................................................17

6 Technical data.........................................................................................................18

6.1 Chuck data.......................................................................................................... 18

6.2 Clamping force / speed diagrams....................................................................... 19

6.3 Calculations for clamping force and speed......................................................... 21

6.3.1 Calculation of the required clamping force in case of a given rpm ........22

6.3.2 Calculation example: required initial clamping force for a given speed

................................................................................................................24

6.3.3 Calculation of the permissible speed in case of a given initial clamping

force........................................................................................................25

6.4 Grades of Accuracy............................................................................................. 26

6.5 Permissible imbalance........................................................................................ 26

7 Attachment.............................................................................................................27

7.1 Pre-assembly measures...................................................................................... 27

7.2 Mounting of the Chuck to the Machine Spindle................................................. 27

7.3 Mounting chuck on Opus B cylinder................................................................... 30

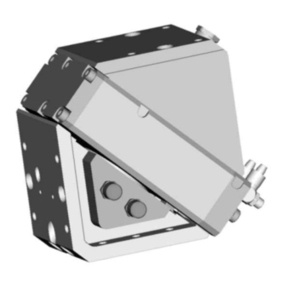

7.4 ROTA 2B S – KONTEC (125 – 315)....................................................................... 31

8 Function .................................................................................................................32

8.1 Function and handling ........................................................................................ 32

8.2 Replacement or renewal of jaws ........................................................................ 32

303.00 | ROTA 2B | Assembly and operating manual | en | 0889059