_________________________________________________________________________________________

schunk.com XND.00041.002_B –05/2022 23

Table of contents:

User information..................................................................................... 241

Purpose of document, validity.................................................................................... 241.1

Illustration of safety features ..................................................................................... 241.2

General safety instructions .................................................................... 252

Intended use ................................................................................................................ 252.1

Technical data ................................................................................................................ 252.1.1

Reasonably foreseeable misapplication..................................................................... 262.2

Alterations and modifications.......................................................................................... 262.2.1

Spare and wear parts and auxiliary material..................................................................... 262.2.2

Residual risk ................................................................................................................. 272.3

Jaw change .................................................................................................................... 272.3.1

Notes on clamping technology........................................................................................ 272.3.2

Duties of the organisation in charge.......................................................................... 27

2.4

Operator duties............................................................................................................ 282.5

Operator qualification................................................................................................. 282.6

Personal protective equipment................................................................................... 282.7

Warranty ...................................................................................................................... 282.8

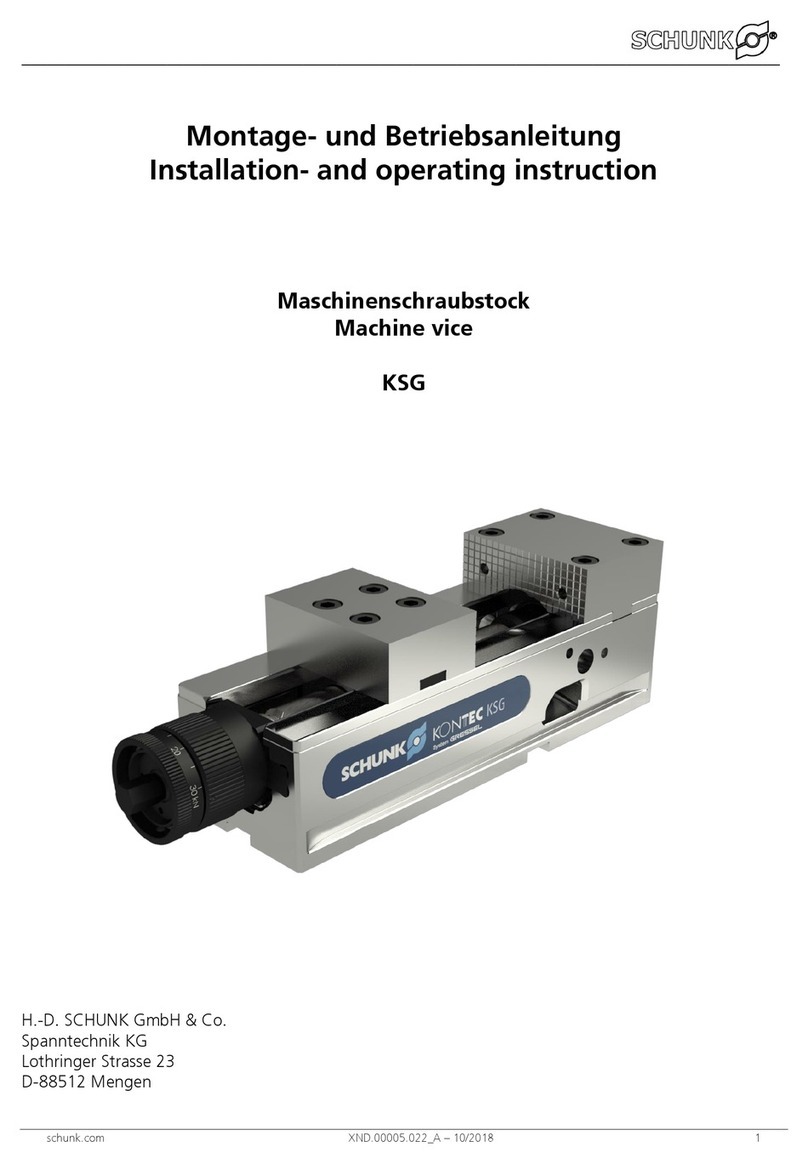

Description of the clamping device ....................................................... 293

Function........................................................................................................................ 293.1

Operation (standard operation)............................................................. 304

Clamping / aligning ..................................................................................................... 304.1

Jaw range..................................................................................................................... 314.2

Fitting the system jaws ............................................................................................... 314.3

Clamping procedure ............................................................................... 325

Precision clamping (without lifting) ........................................................................... 325.1

Raw workpiece clamping (with lift-off) ..................................................................... 335.2

Troubleshooting, eliminating faults ...................................................... 346

General clearing / lubrication ..................................................................................... 346.1

Disasembly / assembly of the spindle ........................................................................ 356.2

Cleaning the spindle.................................................................................................... 356.3

Assembly drawing .................................................................................. 367

Parts list........................................................................................................................ 367.1

Pull rod extension ................................................................................... 378

Swivel and adapter plate ....................................................................... 389

Function........................................................................................................................ 389.1

Servicing, cleaning, maintenance ............................................................................... 389.2

Troubleshooting, eliminating faults........................................................................... 389.3

Removing and replacing parts .................................................................................... 39

9.4

Fitting the 6-fold reversible jaws................................................................................ 399.5

Steel jaws soft......................................................................................... 4010

Precision jaws set.................................................................................... 4011

KSX-C2 125 hydraulic.............................................................................. 4112

Function........................................................................................................................ 4112.1

Risks of hydraulic system ............................................................................................ 4212.2

Pull rod extension ................................................................................... 4213

Taking out of service .............................................................................. 4314

EC declaration of incorporation ............................................................. 4315