JAGUAR CUTTER FOR SX299 MASTER

LOCKING WHEEL NUT REMOVAL SET

MODEL NO: SX299JAG

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! DO NOT use the tool if damaged or thought to be faulty.

WARNING! Ensure that Health & Safety, Local Authority Regulations and general workshop practice Regulations are adhered to

when using tools.

8DO NOT use the tool for a task it is not designed to perform.

8DO NOT use the tool unless you have been instructed in its use by a qualied person.

8DO NOT operate the tool if you are tired or under the inuence of alcohol, drugs or intoxicating medication.

9Maintain the tool in good condition.

9Follow all workshop safety rules, regulations and conditions.

9Wear eye protection, protective gloves and safety footwear.

9 Maintain correct balance and footing. Ensure the oor is not slippery and wear non-slip shoes.

9Keep children and non essential persons away from the work area.

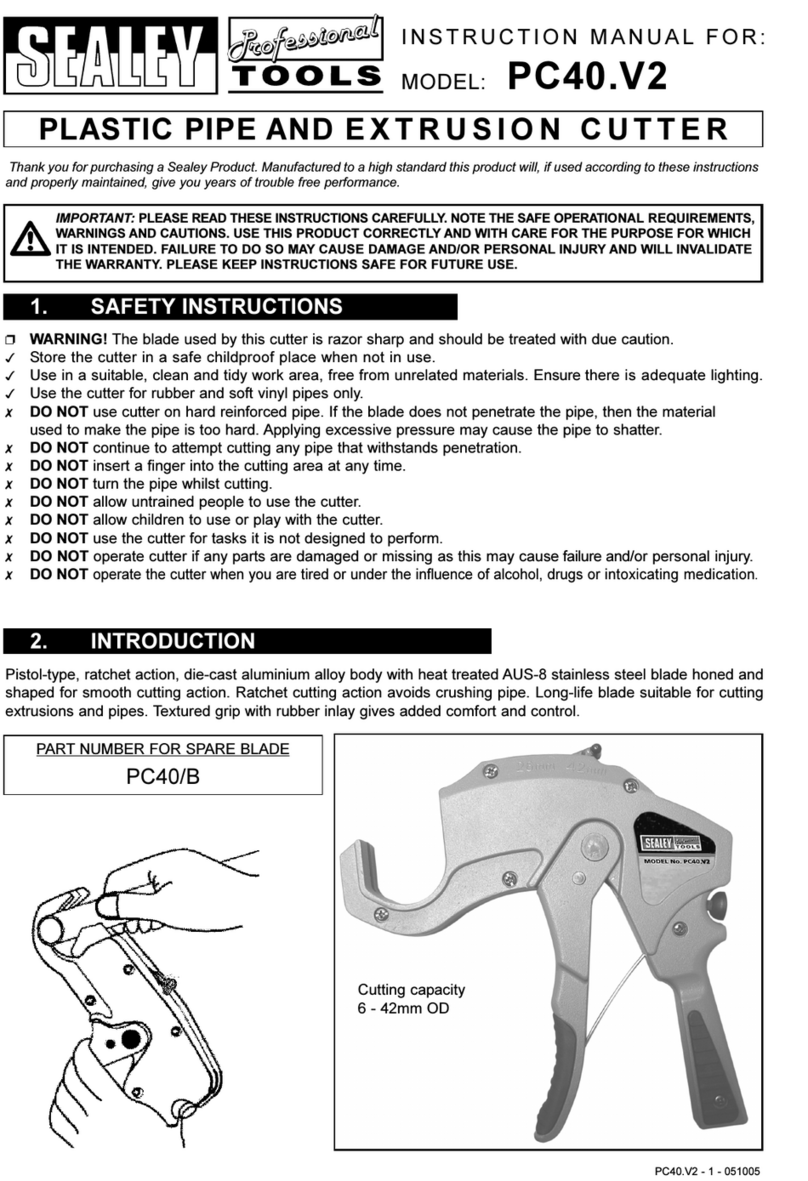

2. INTRODUCTION

Specially designed cutter for use on Jaguar locking wheel nuts. To be used in conjunction with Model No. SX299 Master Locking

Wheel Nut Removal Set

3. CONTENTS

4. OPERATION

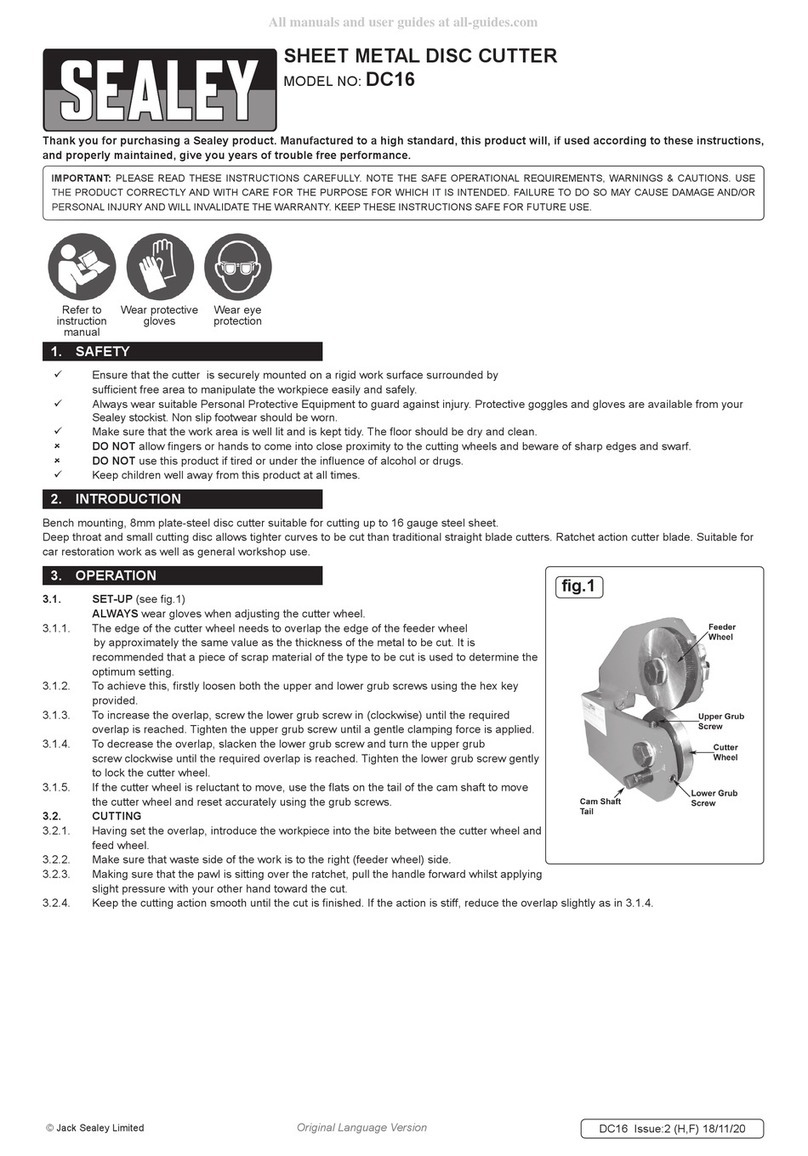

4.1. TOOL ASSEMBLY

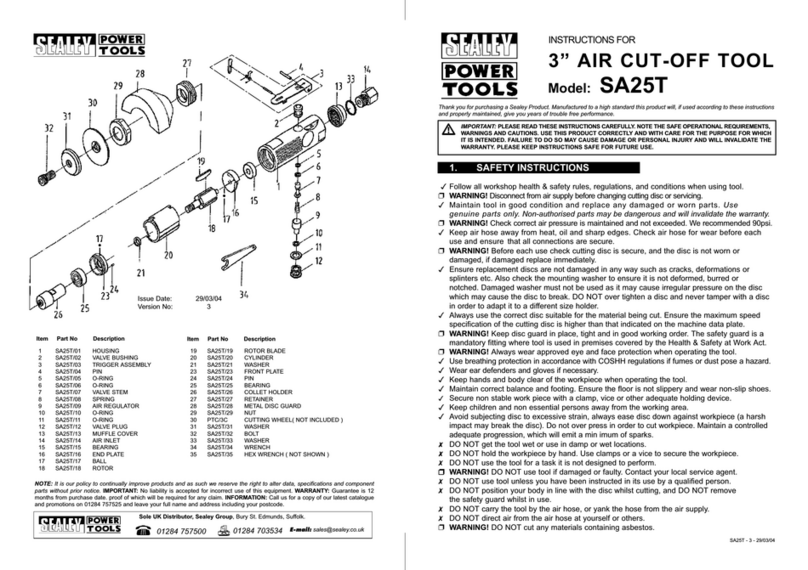

4.1.1. Slide outer shroud (g.1.1) fully down over remover tool body (NOTE: An ‘O’ ring is used to make this a tight sliding t).

4.1.2. Insert key (g1.2) into tool body. Engage and clip in place using the spring ring in tool body.

4.1.3. Slide outer shroud (g.1.1) up over the spring ring to prevent it expanding and the key becoming loose.

4.2. USAGE PREPARATION

4.2.1. Check that the splines (front and back) on the locking wheel nut are aligned.

4.2.2. If not aligned, insert the mandrel (g.1.3) into the key (g.1.2) and locate the key splines with the front splines of the locking wheel

nut.

4.2.3. Rotate the tool to align front and rear splines.

4.3. OPERATION

4.3.1. Once aligned, remove the mandrel (g.1.3) and replace key onto locking wheel nut ensuring re-location of key onto the rear splines

of the locking wheel nut.

4.3.2. Using the impact driver (SX299.V2-01) gradually increase the impact eort ensuring sucient engagement of the key to the rear

splines of the locking wheel nut.

4.3.3. Using the impact drive socket (SX299.08) loosen and remove the locking wheel nut.

5. MAINTENANCE

5.1. Clean with lightly oiled cloth before storing after use.

SX299JAG Issue 1 28/04/20

Original Language Version

© Jack Sealey Limited

Refer to

instructions

g.1

Wear eye

protection

Wear protective

gloves

Wear safety

footwear

No. Description

1 Outer shroud

2 Key

3 Mandrel