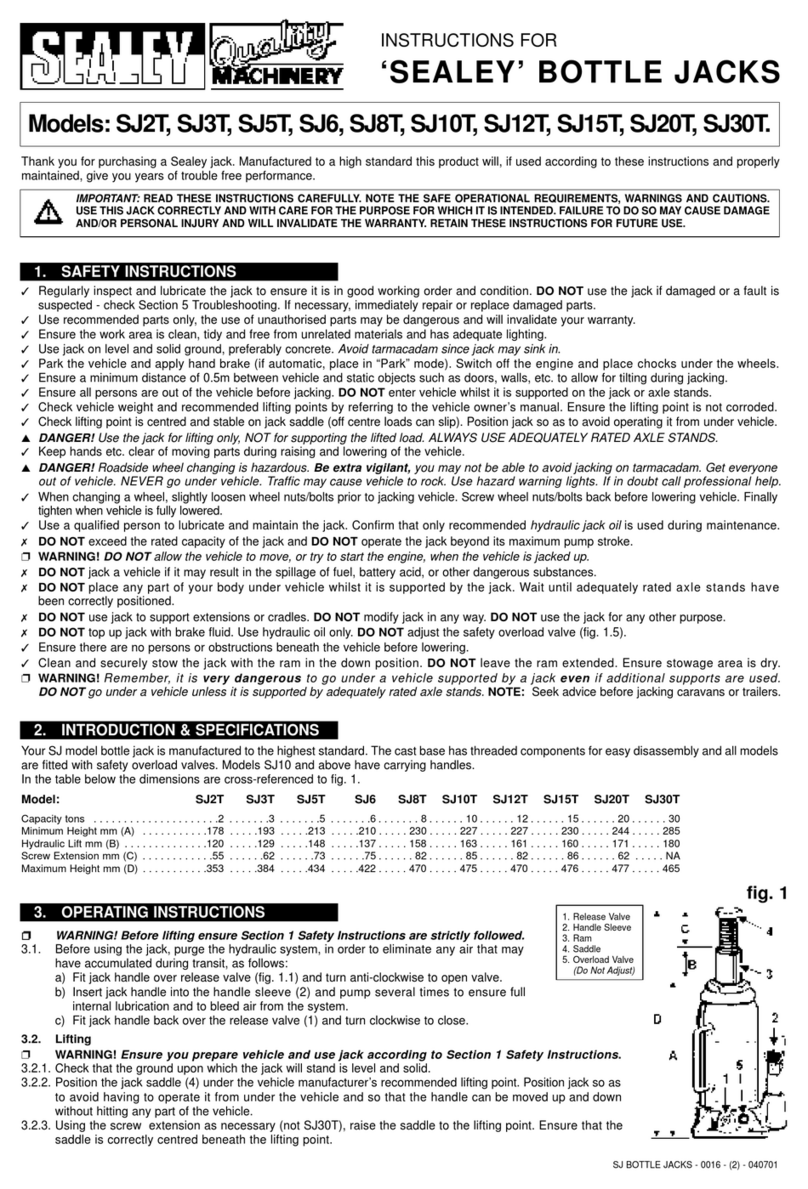

Fig.3

RE97/10.V3 Issue No: 1 16/01/13

Original Language Version

© Jack Sealey Limited 2012

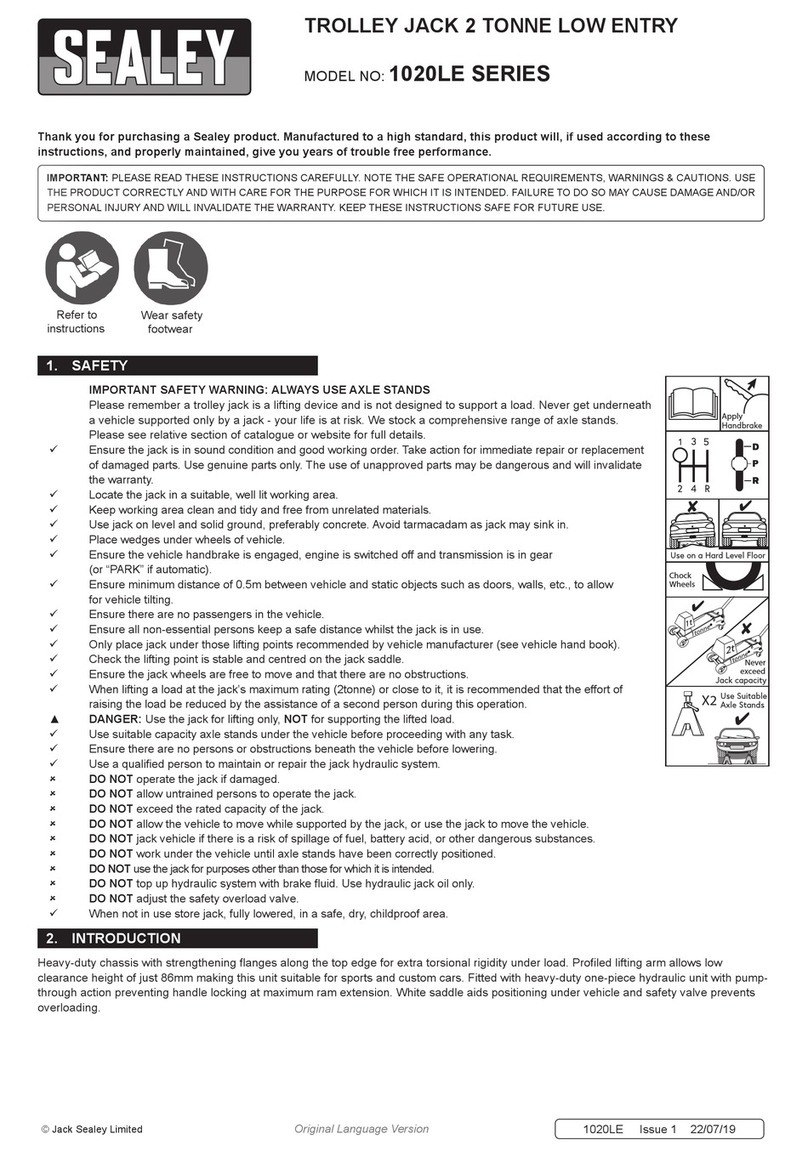

pWARNING! Ensure you have read and understand Section 1 Safety Instructions.

4.1 When using to repair vehicle damage an assessment must be made of all vehicle parts and bodywork distortions. Measurements

should be taken and compared with original manufacturer's specifications. Stored energy (memory) in the areas of damage could

result in sudden stored energy release, causing body shell movements other than the predicted hydraulic ram stroke.

4.2 DO NOT commence operation of ram until you are sure of total deflection requirement. Comprehensive planning for all operations is

essential. Ensure the task undertaken falls within the capacity of the pump and any attachment.

4.3 The pump may be used in any position from horizontal to vertical. When not horizontal ensure the hose end of the pump is

downwards.

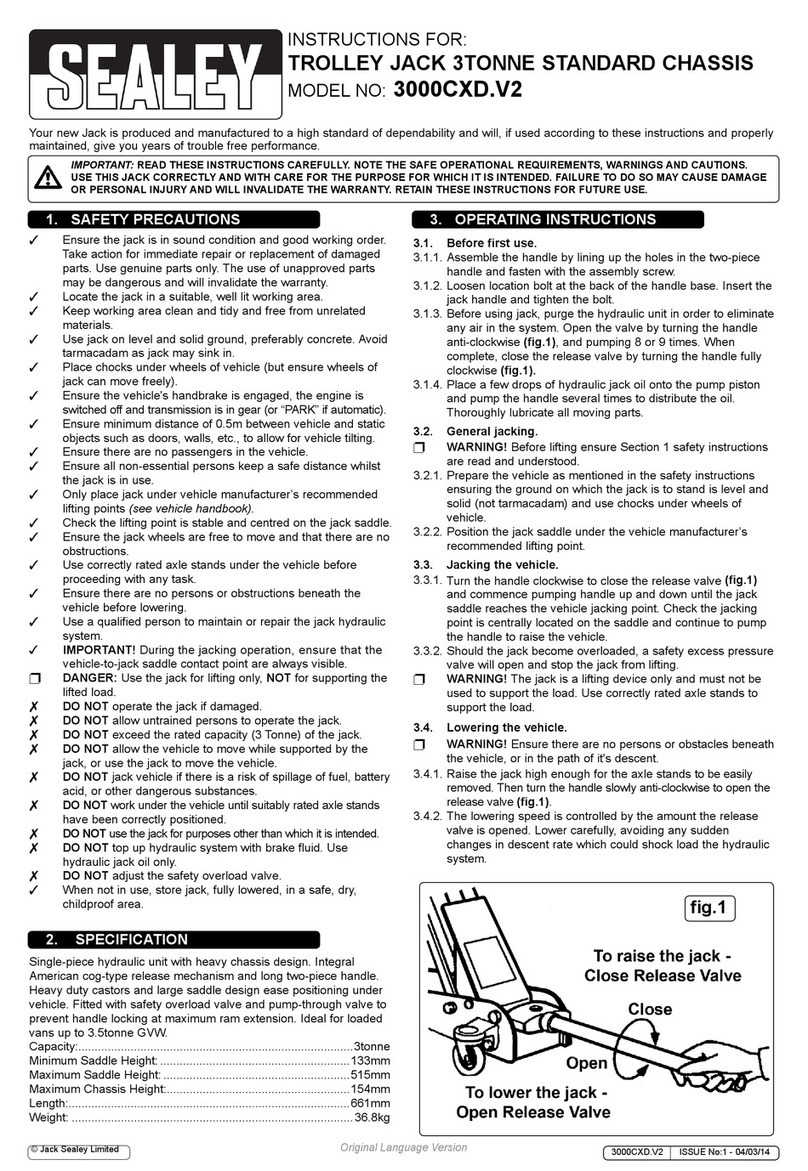

4.4 To use the pump, close valve (Fig.1) by turning the knob clockwise and open the breather valve (which must be closed when not in

use,) pump the handle up and down to apply the load.

4.5 To release pump pressure, turn knob anti-clockwise.

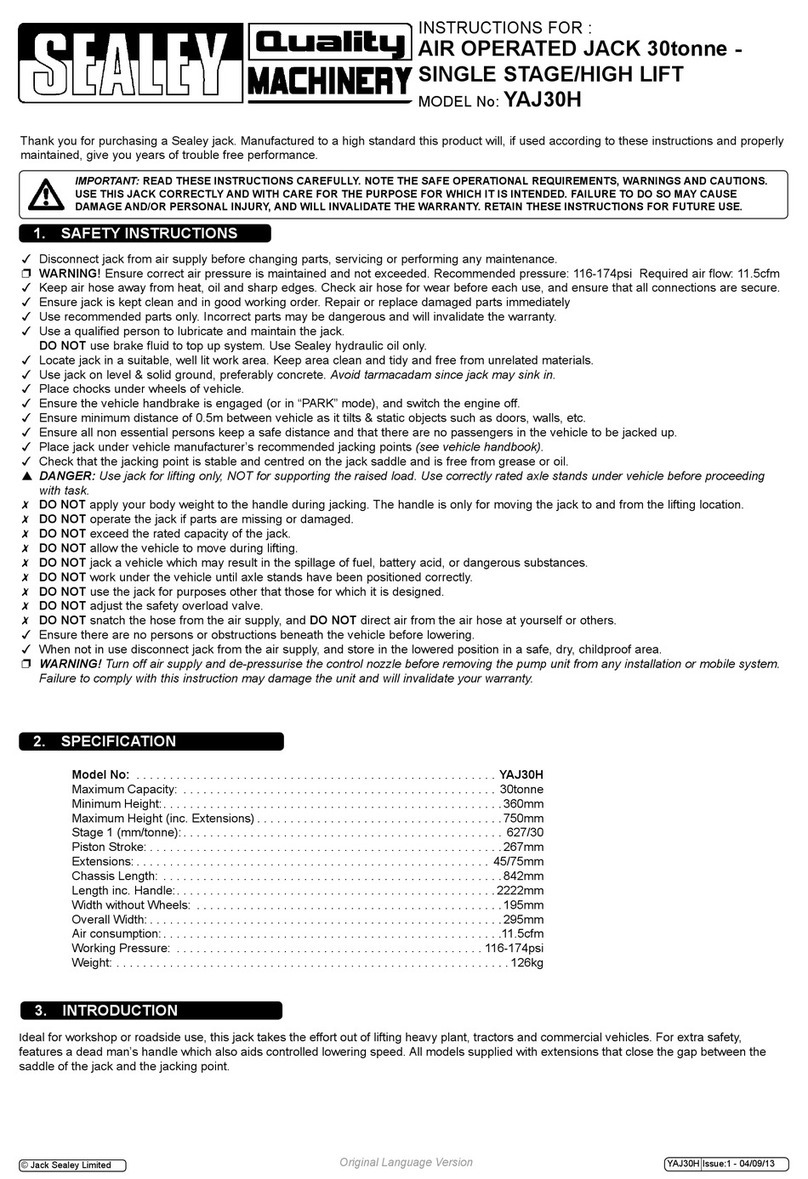

4. INSTRUCTIONS/SPECIFICATIONS

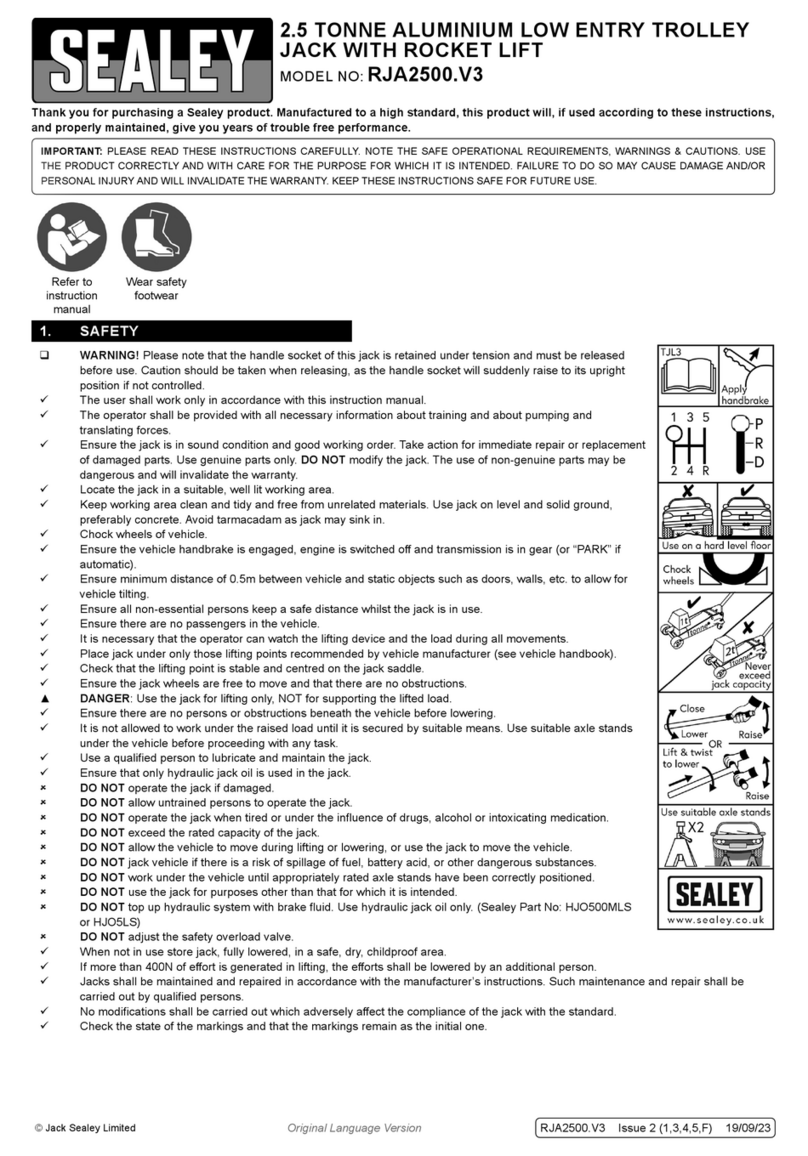

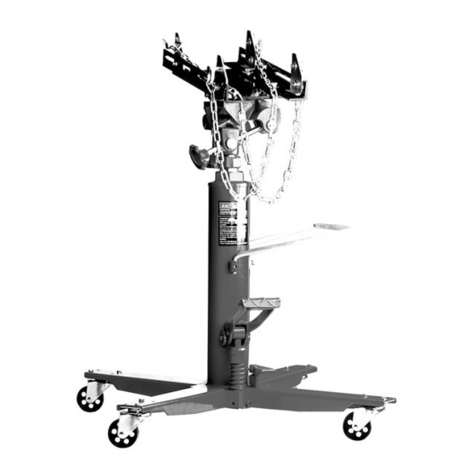

Typical arrangement with base plate attachment.

6. MAINTENANCE

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

IMPORTANT: NO RESPONSIBILITY IS ACCEPTED FOR INCORRECT USE.

Hydraulic products are only repaired by local service agents. We have service/repair agents in all parts of the UK.

DO NOT RETURN PRODUCT TO US. Please telephone us on 01284 757500 to obtain the address and phone number of your local agent.

If product is under guarantee please contact your dealer.

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

01284 757500

01284 703534

sales@sealey.co.uk

www.sealey.co.uk

Web

IMPORTANT: Only fully qualified personnel should attempt maintenance or repair of the hydraulic system.

6.1 Pump oil level

Release pressure and disconnect the ram from the pump.

Hold pump in an upright position.

Ensure the hydraulic ram is fully retracted. Remove the oil reservoir plug on the end and top up using Sealey hydraulic jack oil

(Sealey Part Nos HJO500MLS/HJO5LS). DO NOT use brake fluid. After filling, purge the system in order to eliminate any air. Open

the release valve (Fig.1) and pump the handle several times (suggested 20 times). Close the valve and replace the oil reservoir

plug. Should the system fail at any time, repeating this process may resolve the problem.

6.2 General

Before each use check for broken, cracked, bent, loose parts, or any visible damage to welds, ram, pump, hose or accessories.

Suspect items to be removed from service and repaired or replaced. Repair or replace with genuine parts only. Unauthorised repairs

or parts may be dangerous and will invalidate the warranty.

6.3 De-commissioning hydraulic pump/ram

Should the pump or ram become unserviceable, draw off the oil into an approved container and dispose of the product and the oil in

accordance with local authority regulations.

Snap tubing sections

Pump

Ram

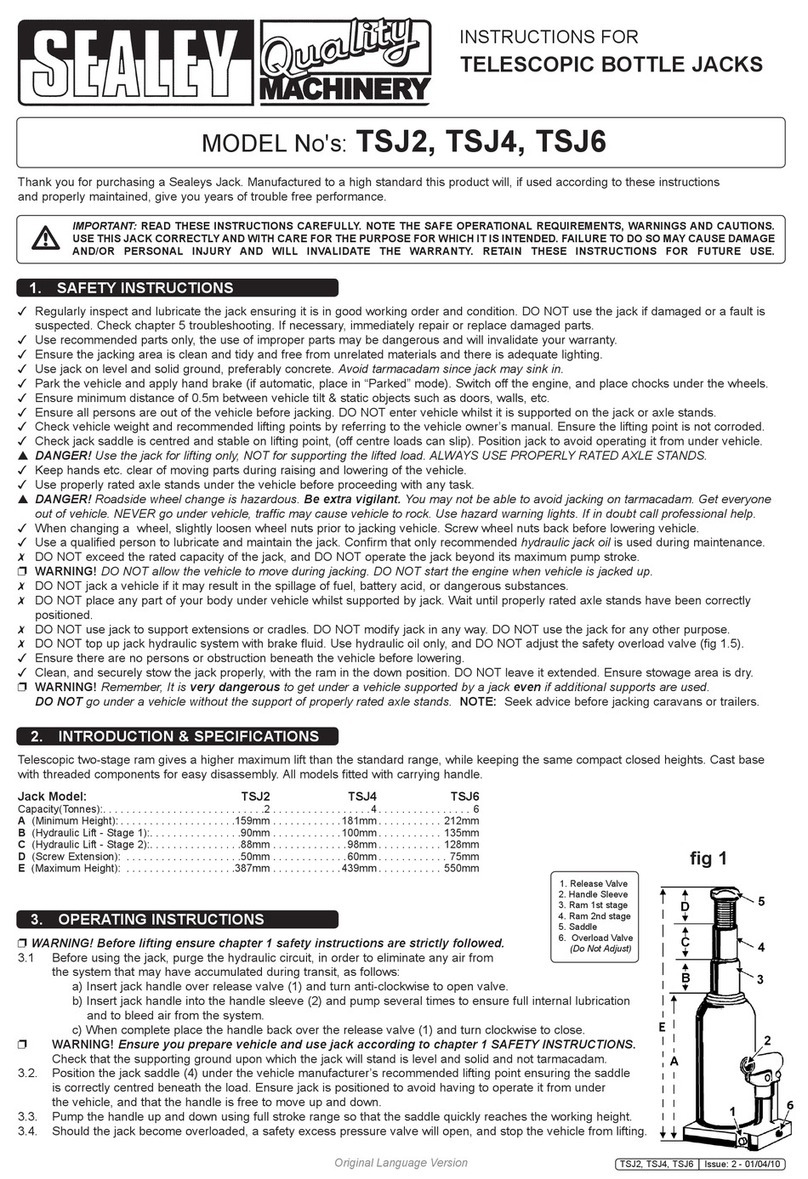

5.1 Hydraulic Ram- For use in large spaces and where a large amount of force is required. Comes with several attachments.

5.2 Snap Tubing- Plug into the hydraulic ram in different combinations in order to obtain the required length.

5.3 Serrated Saddle and Wedge Head- Typically used on the pushing end in frame repair. Can be attached to either the

hydraulic ram or extension bars.

5.4 Flat Base- This is used on the stationary side to spread the force of the hydraulic ram. Can be attached to either the hydraulic

ram or extension bars.

5.5 Male Connector- This is used with the extension bars and other attachments that may be connected to the hydraulic ram.

NOTE! When positioning the hydraulic ram, it is necessary wherever possible to use a smaller attachment on the side that is to be bent or

shaped. To further reduce the danger of the stationary side being damaged, place a block of wood or dense hard rubber behind the flat base

plate (item 11) in order to cushion the stationary side and spread the pressure exerted by the hydraulic ram.

5. ATTACHMENTS

3.1 Unscrew the end plugs from the hose and hydraulic ram. Retain end caps for use when storing the kit.

3.2 Screw the hose into the hydraulic ram. Ensure the hose is secure but DO NOT overtighten.

3.3 Fit the pump handle to the pump unit - DO NOT overtighten.

To provide maximum versatility a combination of pump accessories may be used.

3.4 To use the flat base plate (item 11) and snap tubing sections (items 4-7) with the hydraulic ram, see Fig.3.

3. ASSEMBLY

Fig.1 Fig.2

Close

Release