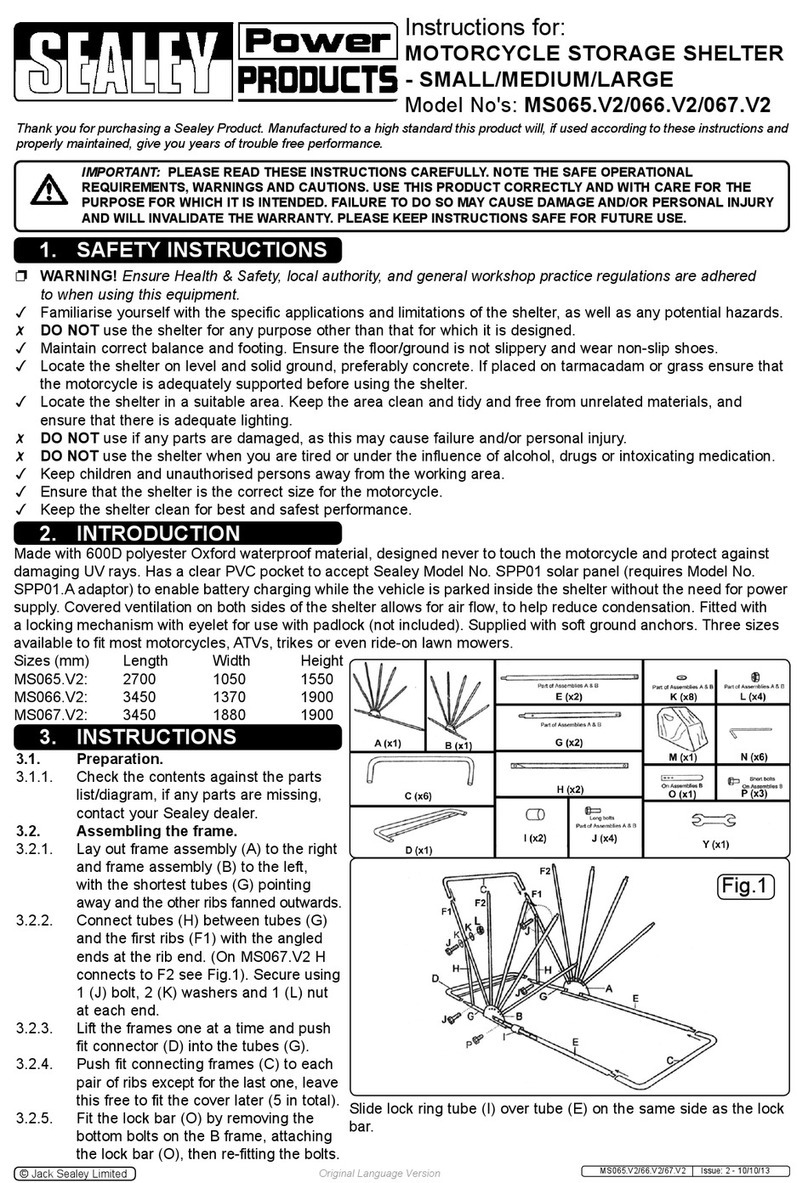

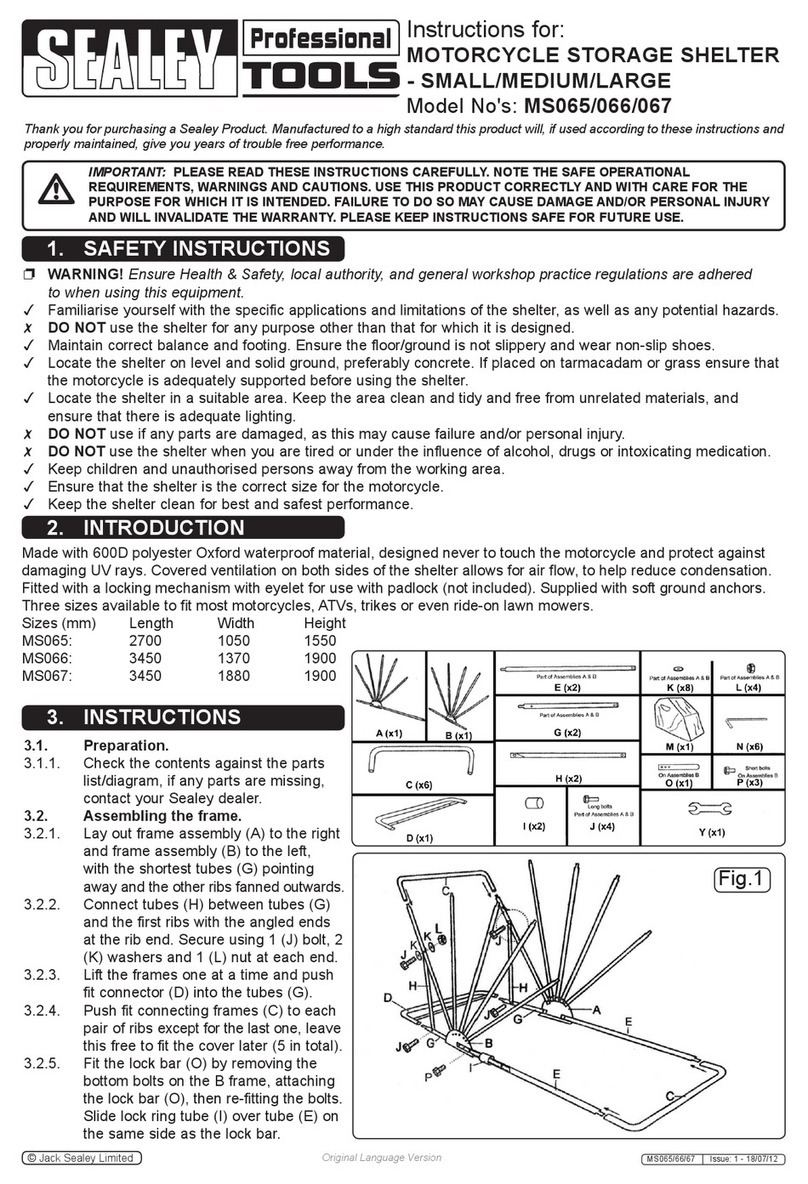

INSTRUCTIONS FOR

MOTORCYCLE FORK SEAL DRIVER KIT 9PC

MODEL NO: MS018.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this

equipment.

WARNING! Always wear approved eye protection when using the kit. Failure to do so may result in serious injury.

9Familiarise yourself with the specific applications and limitations of the kit, as well as any potential hazards.

8DO NOT use the kit for any purpose other than that for which it is designed.

9Ensure that the work piece is stable and that there is adequate lighting.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9Ensure that the front of the motorcycle is adequately supported before removing the front wheel and forks.

8DO NOT use if any parts are damaged, as this may cause failure and/or personal injury.

8DO NOT use the kit when you are tired or under the influence of alcohol, drugs or intoxicating medication.

9Keep children and unauthorised persons away from the working area.

9When not in use, return all parts to the case, and store in a safe, dry, childproof location.

9Ensure that the driver selected is the correct size for the task.

IMPORTANT: These instructions are provided as a guide only. Always refer to the motorcycle manufacturer’s

service instructions, or a proprietary manual, to establish the current procedure and data.

2. INTRODUCTION

Professional kit to cover most diameters of forks. Split design for easy operation on both conventional and USD (inverted) forks for the

installation of fork seals. Hardened and tempered carbon steel, nished with zinc plating for corrosion resistance. Heavy knurled grip gives

positive purchase when in use and limits risk of slip if hands are oily. Limits potential damage to the forks caused by using other installation

methods.

3. SPECIFICATION

Model No.....................................................................MS018

Seal Drivers .......... 35-36,39,41,43,45,46-47,48,49-50,54mm

4. OPERATION

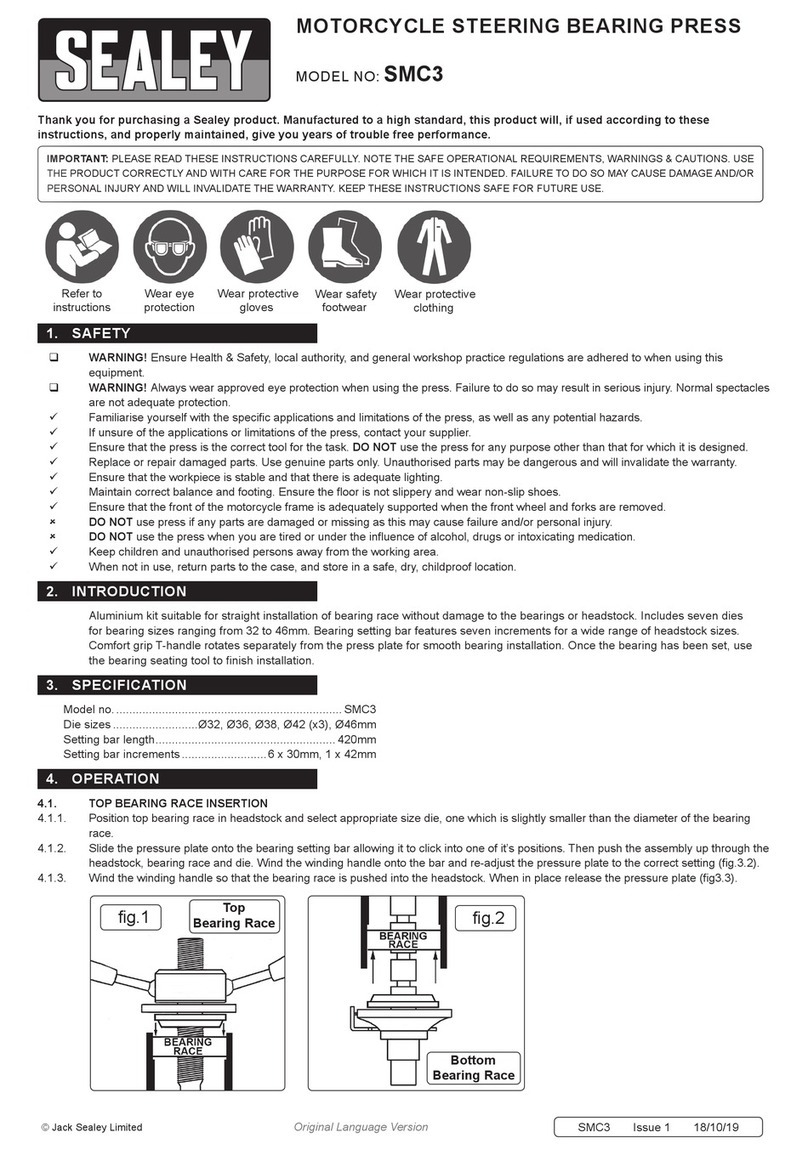

4.1. Remove the front wheel and fork assembly as required, following the

motorcycle manufacturer’s service instructions, or a proprietary manual

for the correct procedure.

4.2. Secure the fork assembly in a suitable holding device.

4.3. Remove the old fork seal.

4.4. Carefully slide a new fork seal onto the fork tube.

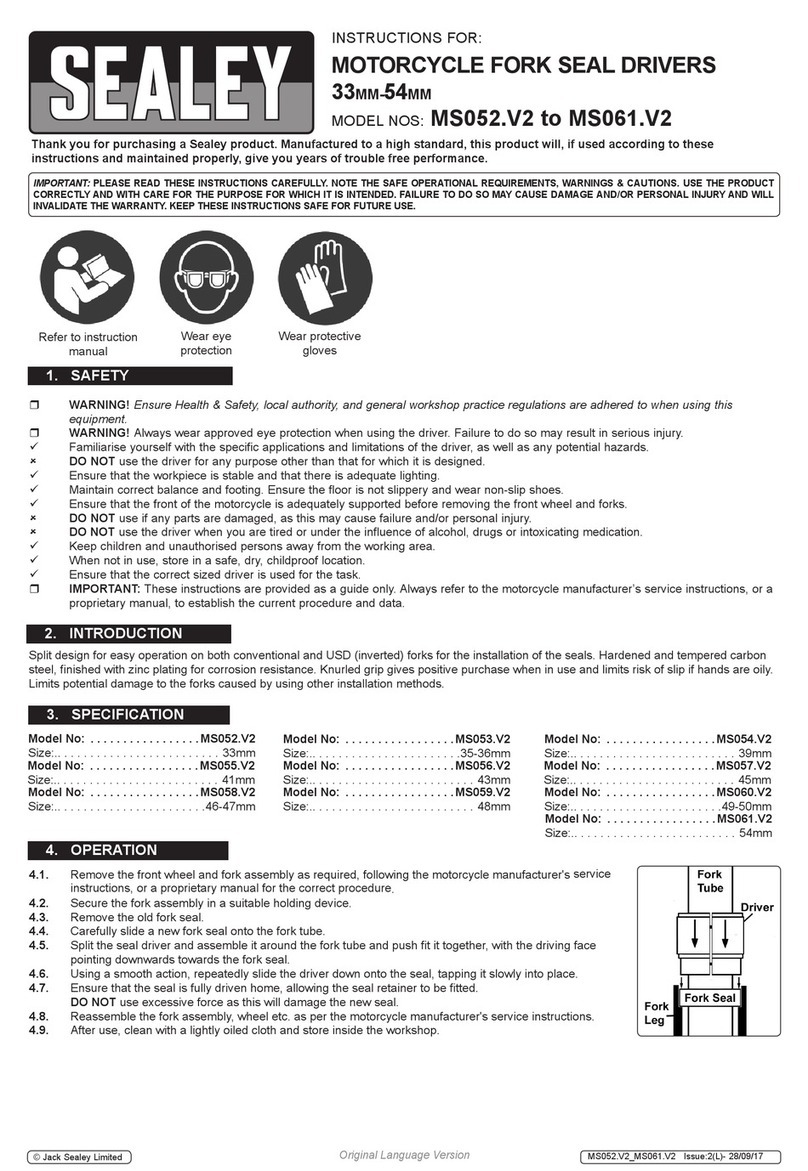

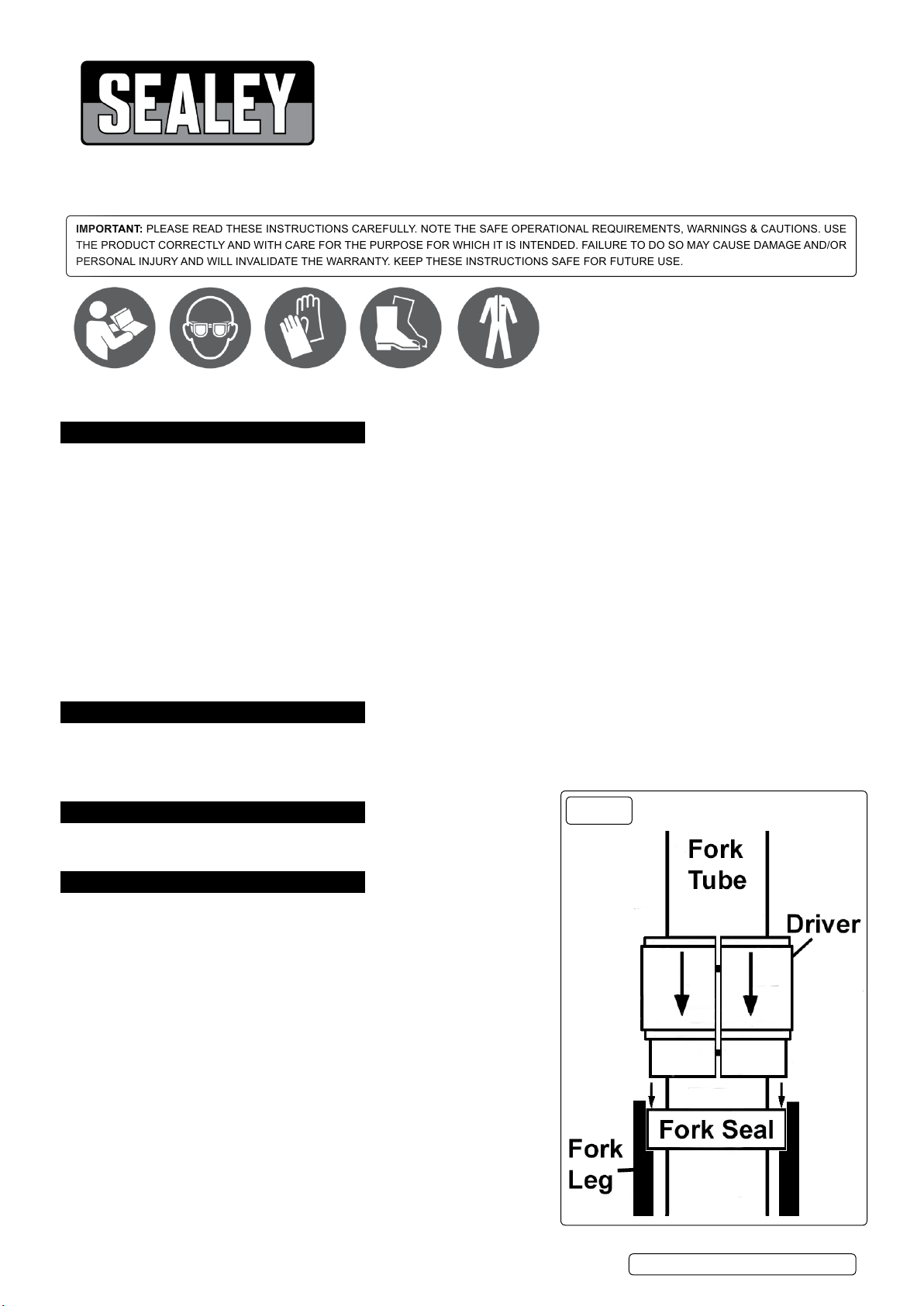

4.5. Select the correctly sized seal driver for the fork tube diameter.

4.6. Split the seal driver and assemble it around the fork tube and push fit

it together,

with the driving face pointing downwards towards the fork seal.

4.7. Using a smooth action, repeatedly slide the driver down onto the new

seal, tapping it slowly into place.

Ensure that the seal is fully driven home, allowing the seal retainer to be fitted.

DO NOT use excessive force as this will damage the new seal.

4.8. Reassemble the fork assembly, wheel etc. as per the motorcycle

manufacturer’s service instructions.

MS018.V2 | Issue 1 20/12/16

Original Language Version

© Jack Sealey Limited

Refer to

instructions

g.1

Wear eye

protection

Wear protective

gloves

Wear safety

footwear

Wear protective

clothing