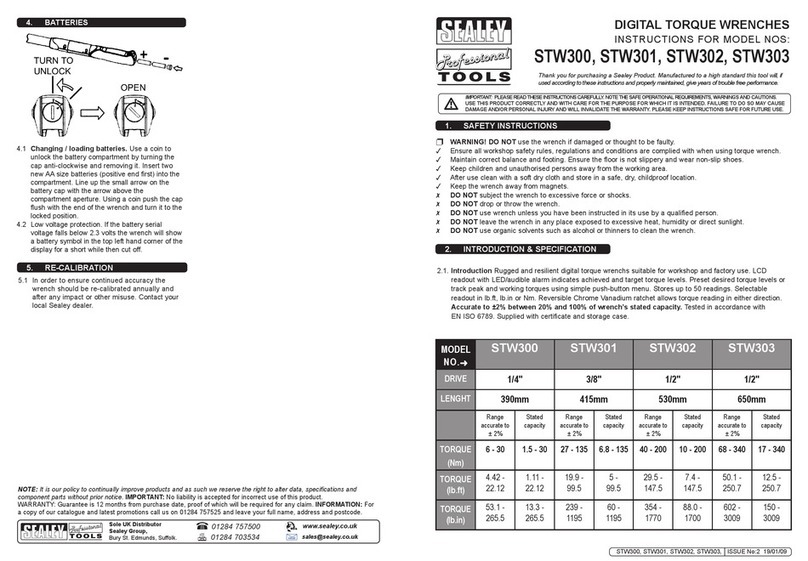

CALIBRATED MICROMETER TORQUE WRENCH

3/4”SQ PUSH-THROUGH DRIVE 237-983NM

MODEL NO: STW601

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETYi

WARNING! DO NOT use the wrench if damaged or thought to be faulty.

Ensure all workshop safety rules, regulations and conditions are complied with when using this torque wrench.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear steel toe-capped non-slip shoes / boots.

9Always wear eye protection when using the torque wrench.

9Keep children and unauthorised persons away from the working area.

9Ensure that all hand tools, sockets and extensions are not damaged, use of such items may result in personal injury.

8DO NOT subject the wrench to excessive force or shocks.

8DO NOT use the torque wrench to break fasteners.

8DO NOT use the torque wrench as a hammer or lever bar.

8DO NOT use extensions on the handle as this may result in damage to the torque wrench and/or cause personal injury.

8DO NOT drop or throw the wrench.

8DO NOT use wrench unless you have been instructed in its use by a qualified person.

8DO NOT leave the wrench in any place exposed to excessive heat, humidity or direct sunlight.

8DO NOT use organic solvents such as alcohol or thinners to clean the wrench.

9Always back off the pressure after use.

9After use clean with a soft dry cloth and store in a safe, dry, childproof location.

2. INTRODUCTION

ManufacturedfromChromeVanadiumsteel.Hardenedandtemperedwithachromeplatedpolishednish.Ratchetheadfeatures

ipreverseactionandpush-throughdrivetoallowtorquingeitherclockwiseoranticlockwise.Comfortgripwitheasy-to-usetorque

adjustment, locks when required setting is selected. Calibration tolerance in accordance with BS EN ISO 6789-1:2017. Suitable

for commercial and industrial applications. Scales graduated in both lb.ft and Nm. Individually tested for ±4% accuracy and issued with

anindividuallynumberedcalibrationcerticate.Suppliedinstoragecasewithpadlock.

3. SPECIFICATION

Model no: ................................................................ STW601

Drive: .......................................................................... 3/4”Sq

Length:..................................................................... 1225mm

Torque range:................................ 237-983Nm (150-750lb.ft)

4. OPERATION

4.1. Toadjustthetorquesetting,pullbackthelockingcollarg.1andtwistthehandleclockwisetotherequiredtorque.

4.2. Forrighthandedthreadsthepushthroughdrivemustbeasshowning.2.

4.3. Forlefthandedthreads,pushthedrivethrough,seeg.3sothatthesockettsontothesamesideasthereversedirectionswitch.

NOTE: The wrench will only torque in one direction as marked by the arrow above the torque scale. Ensure that the torque wrench is

only used in this direction, failure to do so will mean that the incorrect torque will be applied. The reverse switch should always be in

thepositionshowning.2duringthetorquingoperation.

4.4. When using the torque wrench, a click will be heard when the desired torque is reached, DO NOT continue to apply pressure once this

point has been reached.

4.5. When not in use wind the handle back anti-clockwise to release the pressure from the torque wrench.

STW601 Issue 3 (4) 06/11/19

Original Language Version

© Jack Sealey Limited

Referto

instruction

manual

Locking Collar

fig.1

Wear

safety

glasses