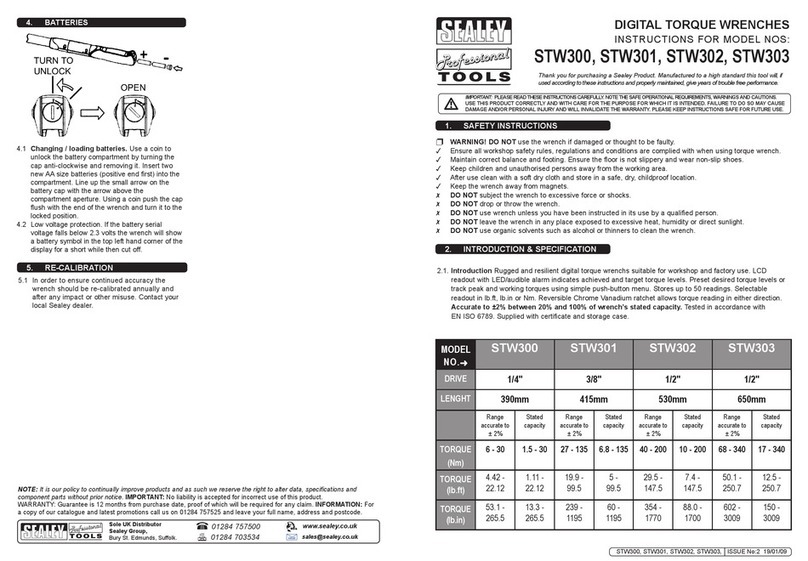

3. SPECIFICATION

Model No:..........................................................YK30ECF

Capacity: ..............................................................30tonne

Floor mounting: ...........................................................Yes

Maximum height - ram to table:.............................610mm

Minimum height - ram to table:............................ -265mm

Overall height:.....................................................1500mm

Ram diameter:......................................................Ø56mm

Ram stroke............................................................180mm

Table aperture:.......................................................140mm

Type:...................................................................Hydraulic

Working table depth: .............................................260mm

Working table width:..............................................655mm

4. ASSEMBLY

Unpack the product and check contents. Should there be any damaged or missing parts contact your supplier immediately. Take care

when removing components from packing as these units are very heavy.

Refer to attached parts list and diagram overleaf.

Seek assistance of another person on assembly of heavy parts.

Assemble press, if possible, in close proximity to where the press will be located. Leave fixings loose until fully assembled then

tighten to ease assembly.

4.1. FRAME ASSEMBLY

4.1.1. With the assistance of another person start the horizontal assembly of the press on a bench, or similar.

4.1.2. Attach the base section (#20) to the upright (#15) and the base support (#14) using M12 x 35 screws (#5), M12 flat washer (#6),

M12 lock washer (#7) and M12 steel nut (#8) loosely.

4.1.3. Repeat for the other side base section (#20).

4.1.4. With the assistance of another person, place the press in an upright position and insert the pin, table support (#13) through the

uprights (#15).

4.1.5. Taking care, lift the table (#16) over the uprights and lower onto the pins, table support (#13). Insert B pins (#21).

WARNING! Take care not to allow the table to drop onto the table pins and ensure your hands and fingers are kept clear.

4.1.6. Taking care, lift the upper support upper support (#19) into position and secure using M16 x 35 hex head screws (#1), M16 flat

washers (#2) and M16 spring washers (#3) attach M16 steel nuts (#4) loosely.

4.1.7. Stand the part assembled press frame onto a flat, level floor and level the frame using a good quality level. Fully tighten all the bolts.

4.2. ATTACHING THE SUPPORT PLATE

4.2.1. Locate the Hook pin (#11) into the support plate (#18) and secure using M8 steel nuts (#12) loosely.

4.2.2. Hook the springs (#10) to the round bars on the underside of the upper support (#19).

4.2.3. Taking firm hold of the support plate (#18) tip it into a diagonal position so it can be introduced between the uprights (#15).

When level attach the hook pins (#11) to the springs (#10).

4.2.4. Adjust the length of the hook pins (#11) using the M8 steel nuts (#12) so that the support plate (#18) is parallel to the upper support

(#19).

4.3. THE HYDRAULIC UNIT

4.3.1. Insert handle (#22) into handle sleeve on the hydraulic unit (#9).

4.4. Place the arbor plates (#17) onto the table (#16).

5. INSTALLATION

5.1. SECURE THE PRESS TO THE FLOOR

WARNING! Always use the assistance of another person when moving the press.

5.1.1. Move the press to the mounting location and spot mark through fixing holes in base section (#20) onto the floor.

5.1.2. Check for any hidden wiring or cables, if needed change the location for the holes.

5.1.3. Temporarily move the press to the side.

5.1.4. Use a masonry drill bit to drill the four holes about 3” to 4” deep into the concrete or wood, as necessary.

5.1.5. Clean out the drilled holes.

5.1.6. Position the press and align the holes in the base section with the holes in the floor.

5.1.7. Use four concrete anchor bolts or lag bolts for wooden floors, (not included), to secure to the floor.

WARNING! To prevent serious injury DO NOT use damaged equipment. If abnormal noise or vibration occurs have the problem

corrected.

5.2. BEFORE FIRST USE

5.2.1. Before operating the press, purge the hydraulic system of the hydraulic unit (#6), in order to eliminate any air that may have

accumulated during transit. Open the release valve and pump the handle several times and close the release valve. Should

the system malfunction at any time, repeating this process may resolve the problem.

▲DANGER! This model is purposefully designed to withstand greater loads than the hydraulic units can develop. For safety reasons,

always ensure the work piece and press tools are secured on the table and will not flex or suddenly “give way” causing danger to

operator or the component. Also ensure you have read and understood section 1 safety instructions.

YK30ECF Issue 1 06/03/23

Original Language Version

© Jack Sealey Limited