WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this equipment.

WARNING!Disconnect from air supply before changing accessories or servicing.

Maintain the tool in good condition (use an authorised service agent).

Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

Use in a suitable, clean and tidy work area, free from unrelated materials. Ensure that there is adequate lighting.

Before each use check pad for condition. If worn or damaged replace immediately.

WARNING! Always wear approved eye or face and hand protection when operating the tool.

Use face, dust, or respiratory protection in accordance with COSHH regulations.

Noise level may exceed 85dB - wear safety ear defenders.

Remove ill fitting clothing. Remove ties, watches, rings, other loose jewellery and contain and/or tie back long hair.

Wear appropriate protective clothing and keep hands and body clear of pad.

Maintain correct balance and footing. Ensure that the floor is not slippery and wear non-slip shoes.

Keep children and unauthorised persons away from the work area.

Check moving parts alignment on a regular basis.

Ensure workpiece is secure before operating the tool. Never hold a workpiece by hand.

Check the workpiece to ensure there are no protruding screws, bolts, nuts, nails, stones, etc.

Avoid unintentional starting.

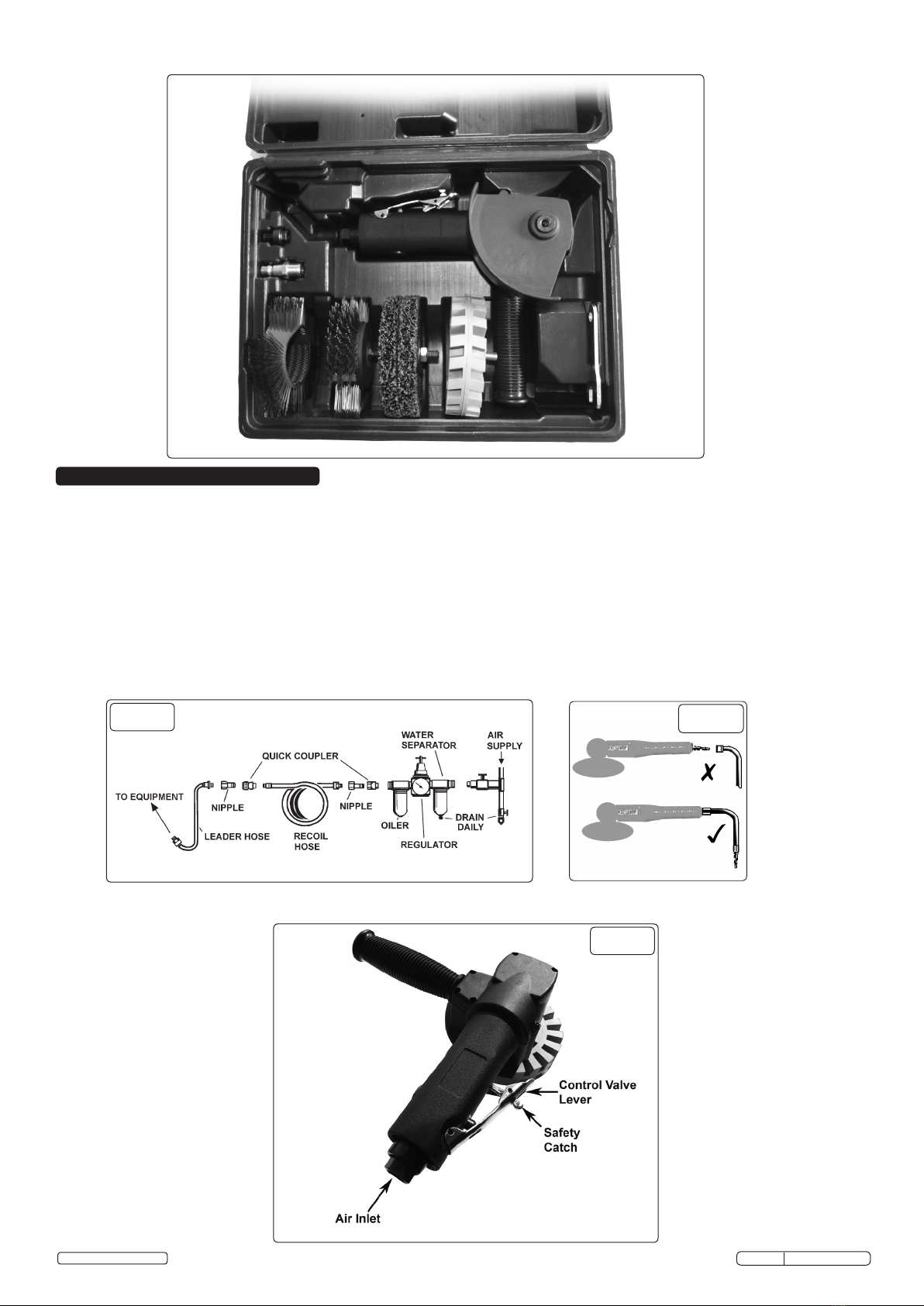

WARNING! Ensure that correct air pressure is maintained and not exceeded. Recommended pressure is 90psi.

Keep air hose away from heat, oil and sharp edges.

Check air hose for wear before each use and ensure that all connections are secure.

Prolonged exposure to vibration from this tool may pose a health risk. It is the owner’s responsibility to correctly assess the potential

hazard and issue guidelines for safe periods of use and offer suitable protective equipment.

DO NOT use a pad which has a speed rating less than the speed rating of the tool.

DO NOT use the tool for a task it is not designed to perform.

DO NOT operate tool if any parts are damaged or missing as this may cause failure and/or personal injury.

DO NOT carry the tool by the hose, or snatch the hose from the air supply.

DO NOT force, or apply heavy pressure to the tool, let the tool do the work.

DO NOT operate tool when you are tired or under the influence of alcohol, drugs or intoxicating medication.

DO NOT carry the tool with your finger on the power lever.

DO NOT direct air from the air hose at yourself or others.

When not in use, disconnect from the air supply and store in a safe, dry, childproof location.

1. SAFETY

INSTRUCTIONS FOR :

SMART ERASER AIR TOOL KIT 4pc

MODEL No: SA695

Original Language Version SA695 Issue: 1 - 03/12/14

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

2. INTRODUCTION

3. SPECIFICATION

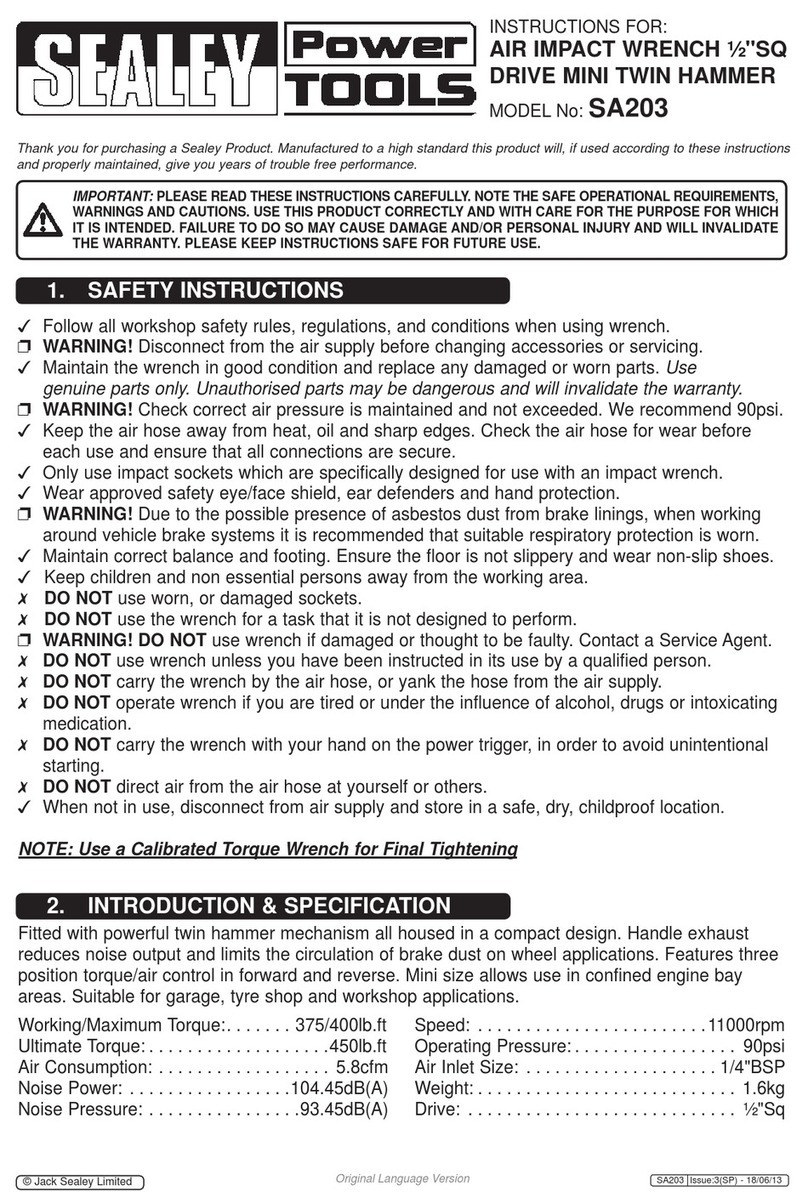

Complete kit for a variety of body preparation tasks. Includes pinstripe removing pad, abrasive wheel and two wire wheels. Powered by specically

designed air tool featuring two handles for maximum control during use. Supplied in storage case. Suitable for the professional workshop. All

pads/wheels are available separately.

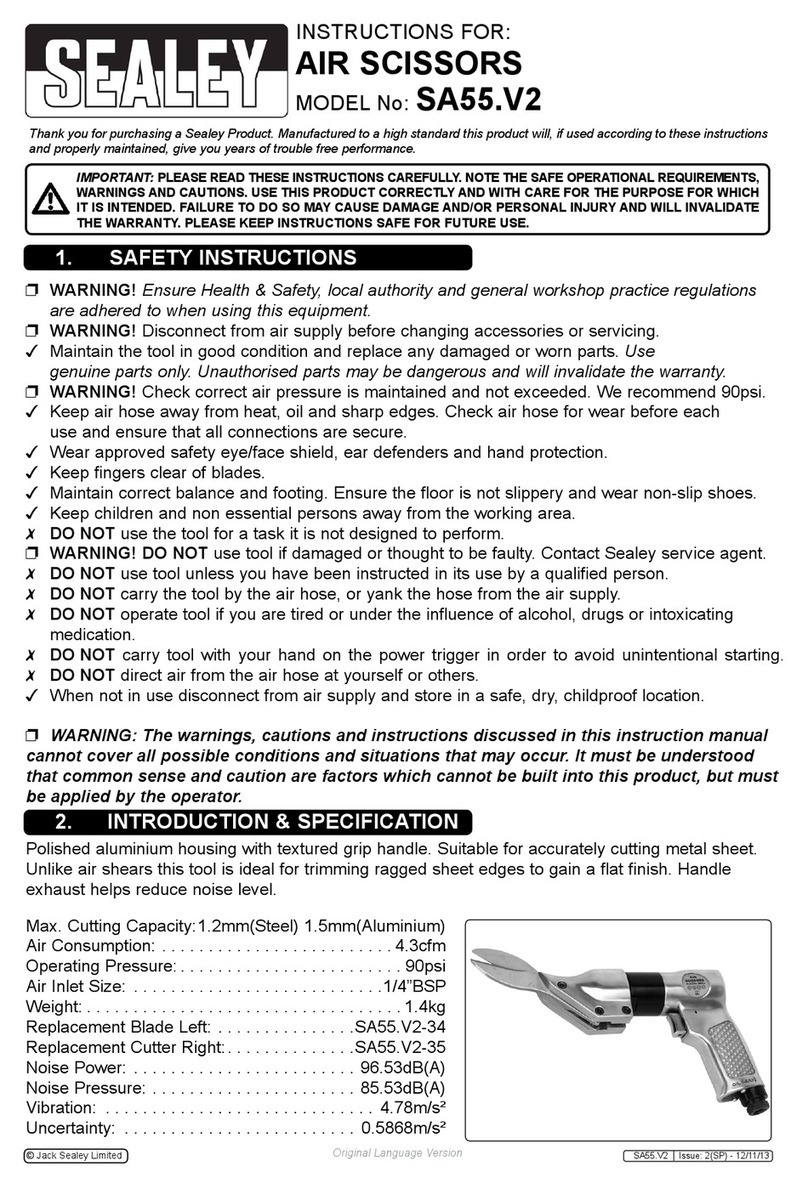

Model No: ................................................................................SA695

Contents: ................................................1 x Pinstripe Removing Pad, 1x Abrasive Wheel

......... 1 x Wire Wheel (Straight), 1 x Wire Wheel (Angled)

Thread Size: ...........................................................................5/16”UNF

Free Speed:.............................................................................3600rpm

Air Consumption:...........................................................................10cfm

Operating Pressure: .........................................................................90psi

Air Inlet Size: ............................................................................ 1/4”BSP

Weight: ...................................................................................1.2kg

Replacement Pad:....................................................................SA95PXPLUS

Replacement Abrasive Disc: .................................................................SA695A

Replacement Wire Wheel:........................................ SA695WS (Straight), SA695WA (Angled)

Noise Power/Pressure: ................................................................98dBA/87dBA

Vibration/Uncertainty: ..............................................................0.5m/s² /0.55m/s²

© Jack Sealey Limited

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL

INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Refer to

Instructions

Wear Ear

Protection

Wear Eye

Protection

Wear Protective

Gloves Wear a Mask