AK467D, AK467DXP Issue No.1 09/10/09

Original Language Version

1. SAFETY INSTRUCTIONS

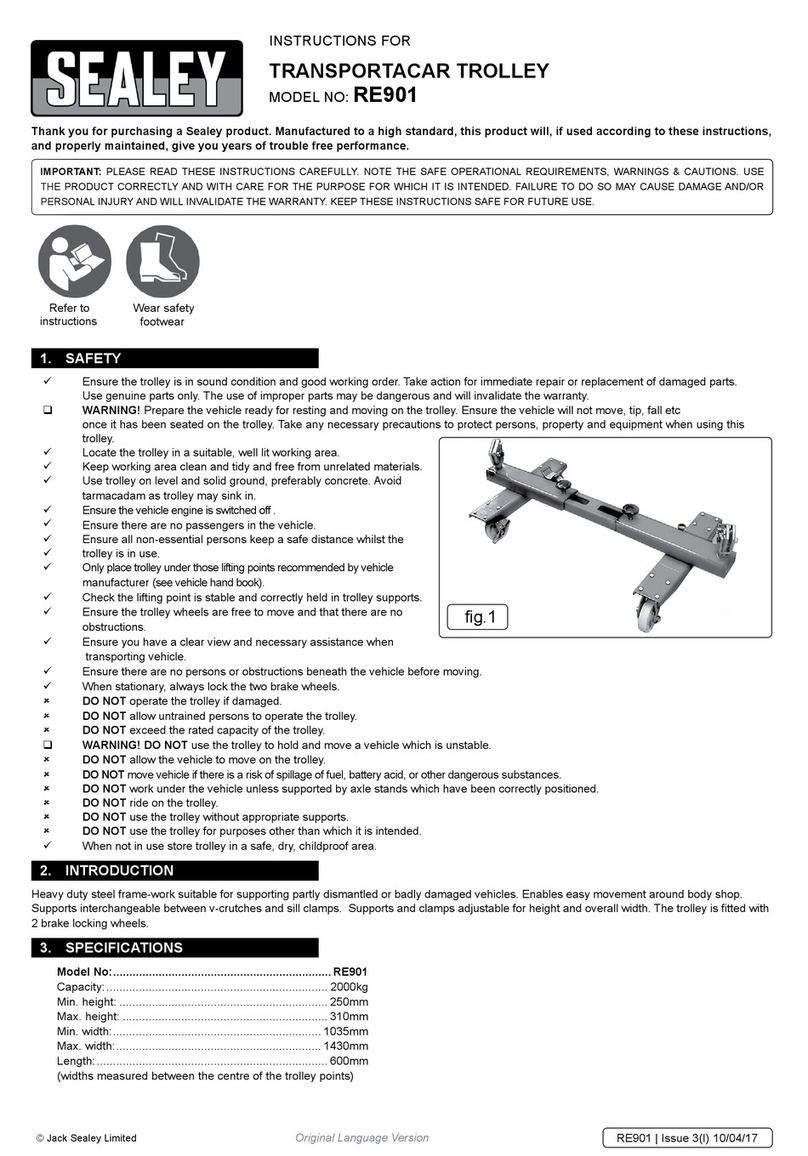

Low level drainer suitable for use on the forecourt and

workshop floor. Steel fabricated unit with a capacity of 64ltr.

Fitted with gravity drain tap for manual discharge (AK467D) or

rotary pump for fast discharge (AK467DXP).

Fully portable with two castors, two fixed wheels and handle for

manoeuvring around the workshop.

Specification:

Capacity:................................................................................64ltr

Minimum Height to Pan:...................................................285mm

Maximum Height to Pan:..................................................285mm

Gravity Feed:.......................................................................... Yes

Suction Probe:......................................................................... No

Gravity Discharge:.................................................................. Yes

Air Discharge:.......................................................................... No

Pump Discharge:.......................................Yes (AK467DXP only)

2. INTRODUCTION & SPECIFICATION

Replace damaged parts. Use recommended parts only.

Unauthorised parts may be dangerous and will invalidate the

warranty.

Keep the drainer clean, dry and in good condition for best and

safest performance.

Wear appropriate protective clothing and eye protection.

If it is necessary to raise the vehicle ensure that it is properly

supported. If the vehicle has been raised with a jack, axle

stands must be put in place before working under the vehicle.

Remove the oil drainer and other tools and equipment from

underneath the vehicle before lowering it again.

Use drainer in a suitable work area. Keep area clean and tidy,

and free from unrelated materials and ensure that there is

adequate lighting.

The work area should have a flat and level surface capable of

supporting the weight of the drainer and it's contents.

DO NOT position the drainer in such a way that it becomes a

hazard to others in the work area.

Ensure that the floor is not slippery and wear non-slip shoes.

Keep children and unauthorised persons away from the work area.

Dispose of waste liquids in accordance with local authority

regulations.

WARNING! DO NOT allow uncontrolled discharge of fluids

which would pollute the environment.

DO NOT use the drainer in wet or damp areas or where

condensation is present.

DO NOT use the drainer near open flames or other sources of

heat.

WARNING! If draining the oil whilst hot, take precautions to

prevent against burns, particularly hands, wrists and arms.

INSTRUCTIONS FOR:

LOW LEVEL OIL DRAINERS

MODELS: AK467D, AK467DXP

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS, AND

CAUTIONS. USE THIS PRODUCT CORRECTLY, AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO

MAY CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY.

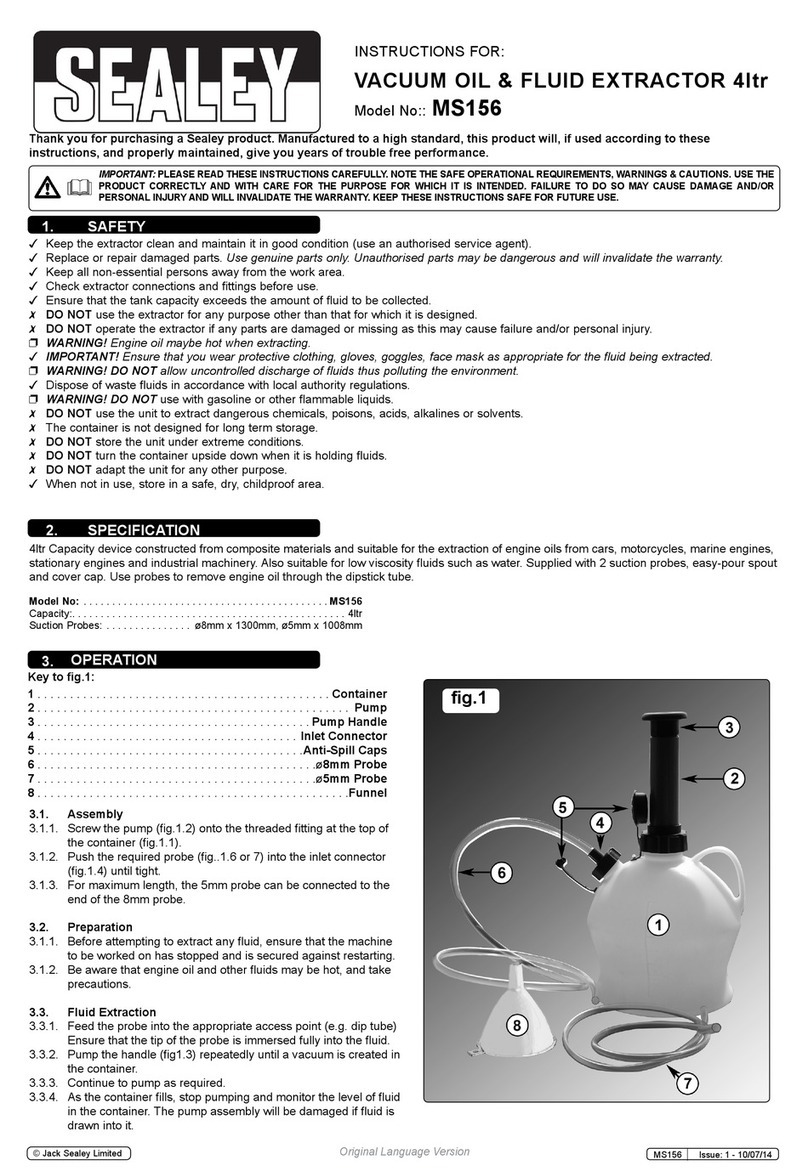

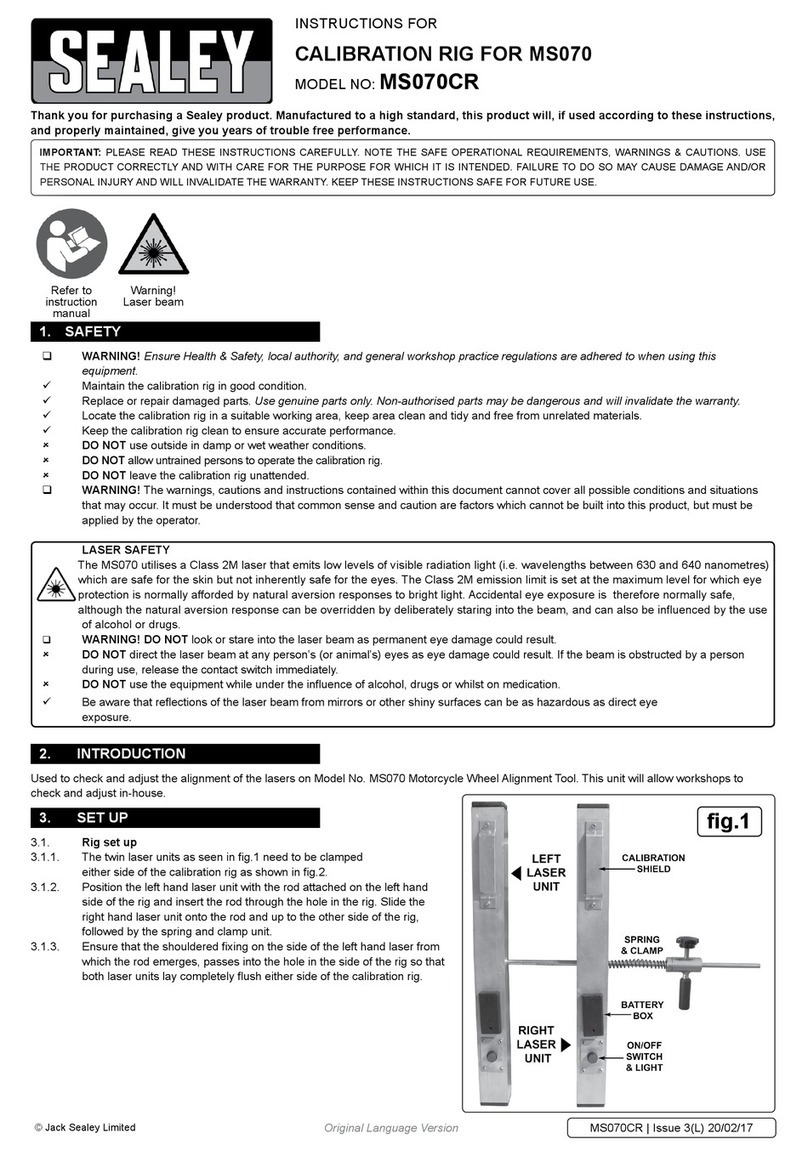

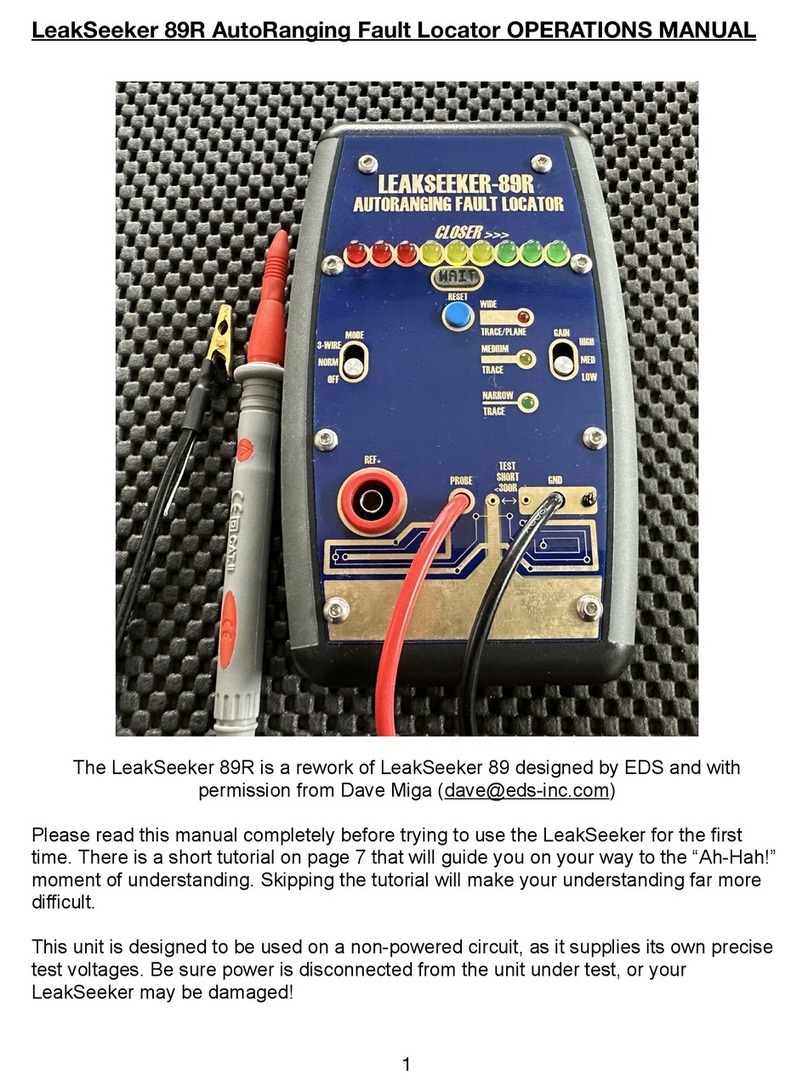

fig.1

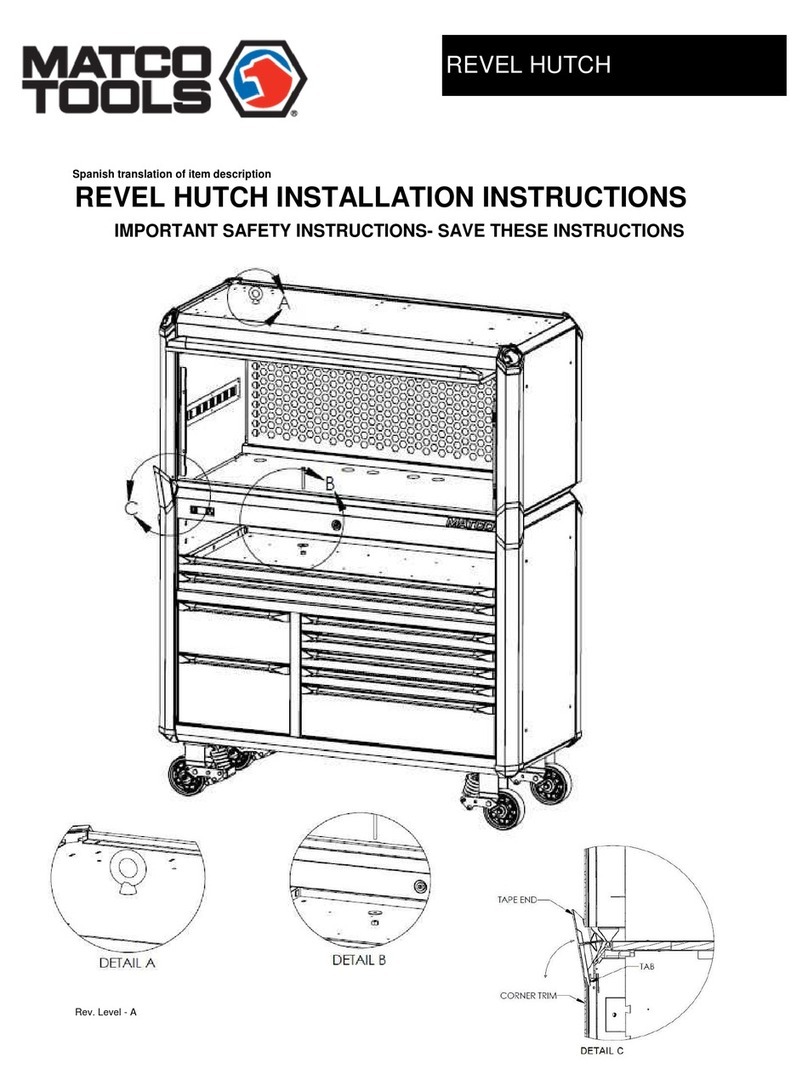

fig.2

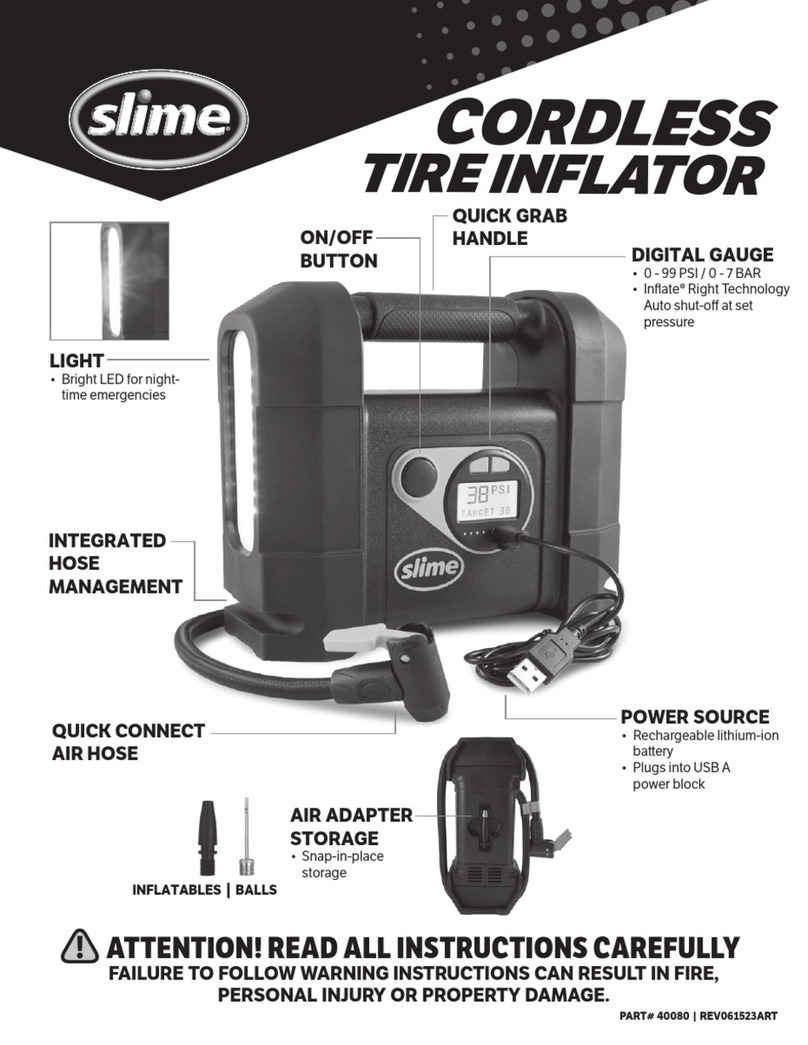

fig.3

3.1 Assembly

3.1.1 CASTOR WHEELS. Bolt a castor wheel to each of the

projecting brackets either side of the handle mount using the

M12 nuts and washers provided, as shown above in fig.2.

3.1.2 FIXED WHEELS. Insert the special axle bolts through each

wheel so that the wheel is running on the roller bearing.

Mount each wheel by pushing the axle bolt through each of

the tubular axle mounts welded to the back, bottom edge of

the casing. Secure each axle bolt with the M12 lock nuts

provided. Do not over tighten.

3. ASSEMBLY