5. MAINTENANCE 5.2.5. Take small seal and piston (fig.5.7 & 8) and gently push them

down the narrow bore of the cylinder ensuring the metal piston

(8) is first, with the concave face pointing in the direction of the

T-handle, and the seal (fig.5.7) second, with the widest part of

the seal facing upwards towards the main cylinder (fig.5). Push

into bore as far as possible.

5.2.6. Pour 15grms of oil into the bore (fig.6). Insert larger seal (fig.7.6)

as shown, with the widest part of the seal facing downwards into

the bore. Push down into main cylinder as far as ‘X’ (fig.7)

followed by piston (fig.7.4) and spring (fig.7.3).

5.2.7. Refit (do not overtighten) ram cover (fig.7.2) and replace

T- handle (fig.7.5).

WARNING! The correct orientation of pistons and seals in

the ram is critical.

5.2.8. Screw T-handle into ram until it contacts small piston and

then turn a further two or three times.

5.2.9. Remove T-handle and firmly bounce the ram piston (fig.8) on a

hard, but non-damaging, surface 6

to 10 times to consolidate the oil.

Replace the T-handle, wipe clean and

the ram is ready for use.

fig. 3 fig. 4

fig. 7

5.1. GENERAL

5.1.1. Keep all items clean and lightly oiled. Keep all threads free from

grit and lubricate the ram regularly.

5.1.2.

Store the ram in the closed position to prevent piston surface corrosion.

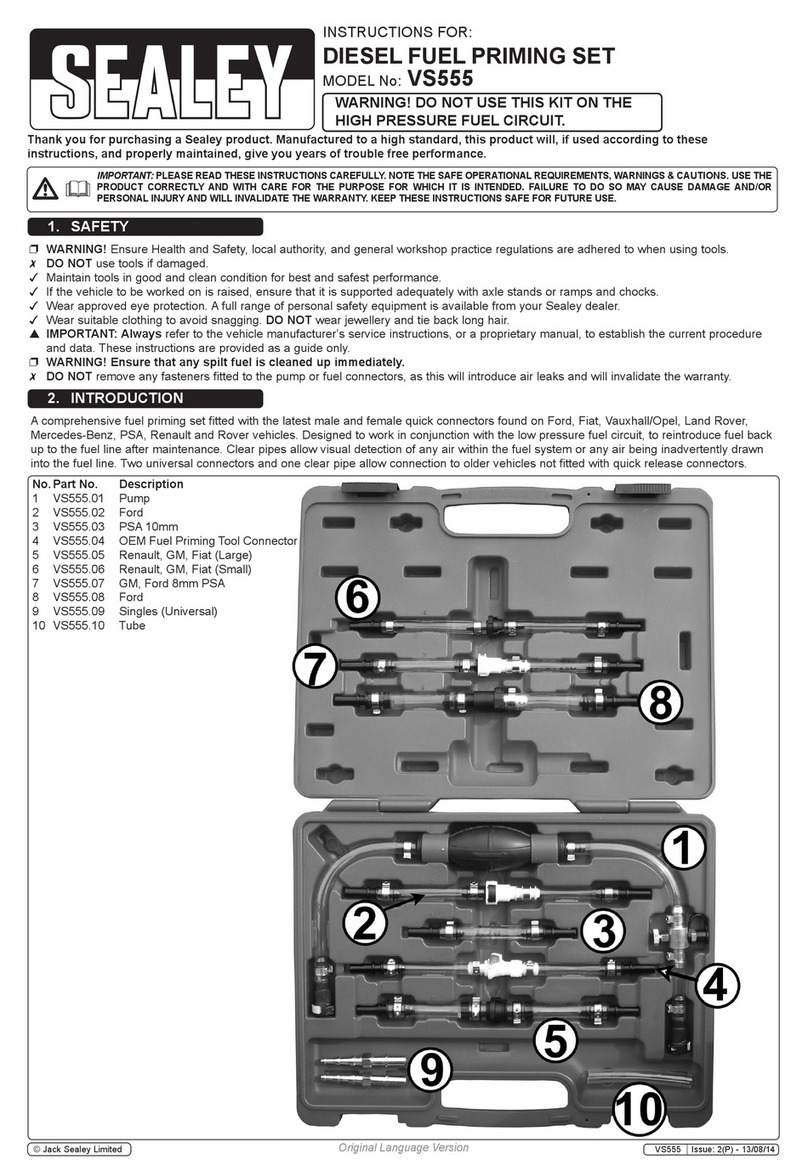

5.2. TO CHANGE OIL IN RAM

IMPORTANT: The hydraulic system operates on a specially

formulated oil which must be replaced from time to time.

Use Sealey Hydraulic Jack Oil, available from your

authorised Sealey dealer. Quote model number:

HJO500MLS for 1 x 500ml bottle or PS982/OIL for 15grms

of oil for a single refill.

WARNING! Use of any other oil in ram may cause ram to

fail and will invalidate your warranty. Wear appropriate eye,

face and hand protection.

5.2.1. Dismantle by removing the ram cover (fig.3.2) with soft jaw grips

(fig.3.A) (body may have to be held in a soft jaw vice, ensure

body thread is not damaged). Caution! The cover is spring

loaded, take care when removing. Carefully remove

components 2, 3, and 4 from the cylinder.

5.2.2. Screw T-handle (fig.4.5) down as far as it will go, then unscrew

and remove it from the body (fig.4.5).

5.2.3. Push a narrow screw driver (fig.4.9), or a rod of appropriate

diameter, down the small opening in head of ram (B), in order to

push components 6, 7, and 8, plus the oil, out of the main

cylinder. Note: A medium force may be required.

5.2.4. Remove remaining oil from main cylinder, clean all components

and replace any showing signs of damage or wear.

fig. 6

fig.8

6.0. MAINTENANCE OF EARLY MODELS.

Please note that earlier models of the

PS990 were filled with a hydraulic

grease.

WARNING! Do not put oil into units

previously filled with grease as the

seals will be configured for grease only

and will leak if used with oil.

6.1 CONVERTING OLD UNITS TO OIL

The old type grease filled PS990 can

be converted for use with oil by

replacing the internal components with

those supplied in the repair kit

shown on left Part No. PS982.V2-RK.

Do not mix old and new components.

A single 15grm refill of oil may be

obtained by quoting Part No.PS982/OIL

6. SERVICE PARTS & NOTES

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

www.sealey.co.uk

Web

email

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our catalogue and latest promotions call us on 01284 757525 and leave your full name, address and postcode.

PS990.V2 Issue No.1 - 12/12/08

fig. 5