This range of 1.6 BMW 4 cylinder twin camshaft 16v. petrol

engines have VANOS (VCT) units on inlet and exhaust

camshafts but are not Valvetronic engines.

The N40 was introduced in the BMW 3 Series (E46) in 2001,

followed by the N45 in the 1 Series (2003). The N45T appears in

both the 1 Series and 3 Series from 2006.

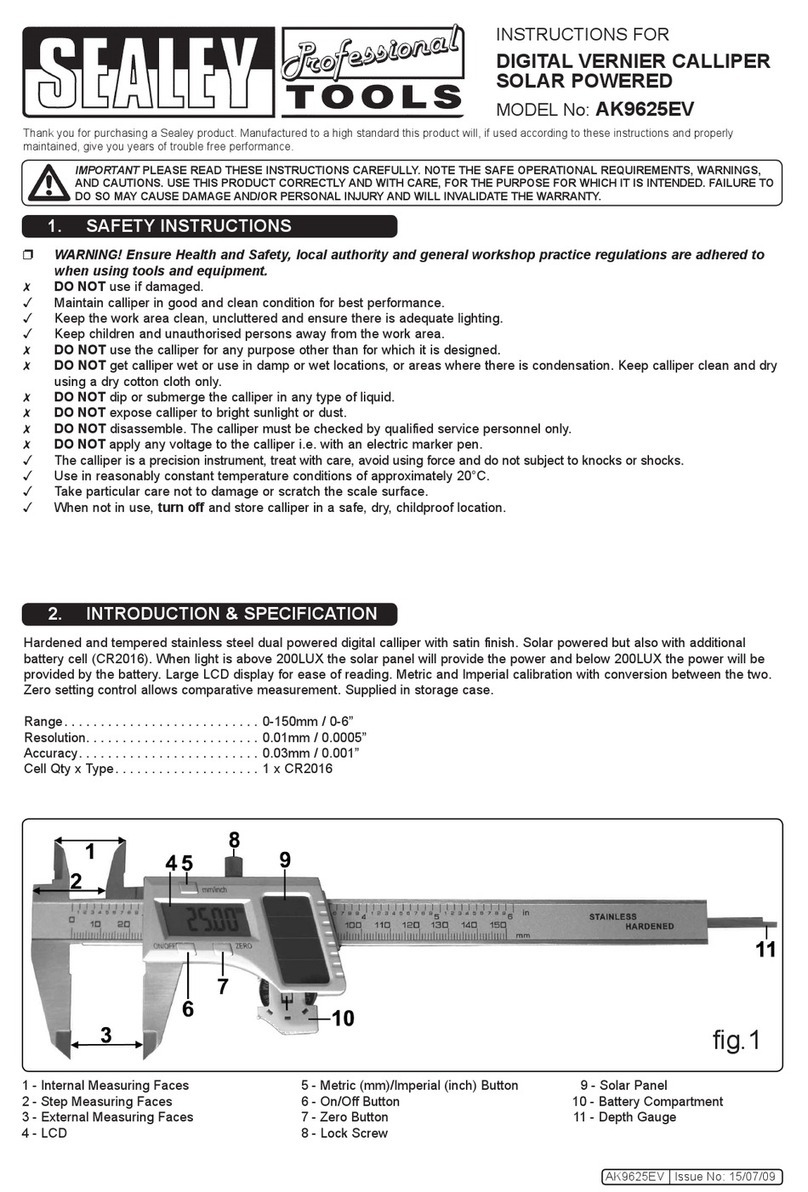

VS4870 Setting/Locking Tool Kit

Comprises: VS4801 Flywheel Locking Pin

VS4803 Chain Tensioner Pre-Load Tool

VS4868 Camshaft Setting Plate Assembly

Comprises: VS4868-1 (Inlet Plate)

VS4868-2 (Exhaust Plate)

VS4805-3 (Securing Screw)

VS4869 VANOS Alignment Plate

For checking and adjusting valve timing, the timing positions for

the camshafts are achieved using the VS4868 Camshaft Setting

Plate Assembly and the VS4803 Timing Chain Tensioner Pre-

Load Tool.

ThecrankshaftislockedatTDC(viatheywheel)usingVS4801

Locking Pin.

The VANOS Units positions are adjusted with VS4869 Alignment

Plate.

3.1 Checking valve timing

3.1.1 Remove the cylinder head cover and all spark plugs.

Unscrew the bolt retaining the oil supply line and unclip the line.

Turn the crankshaft, in normal direction of engine rotation, to

TDC No.1 cylinder (ignition), using a wrench on the crankshaft

pulley centre bolt.

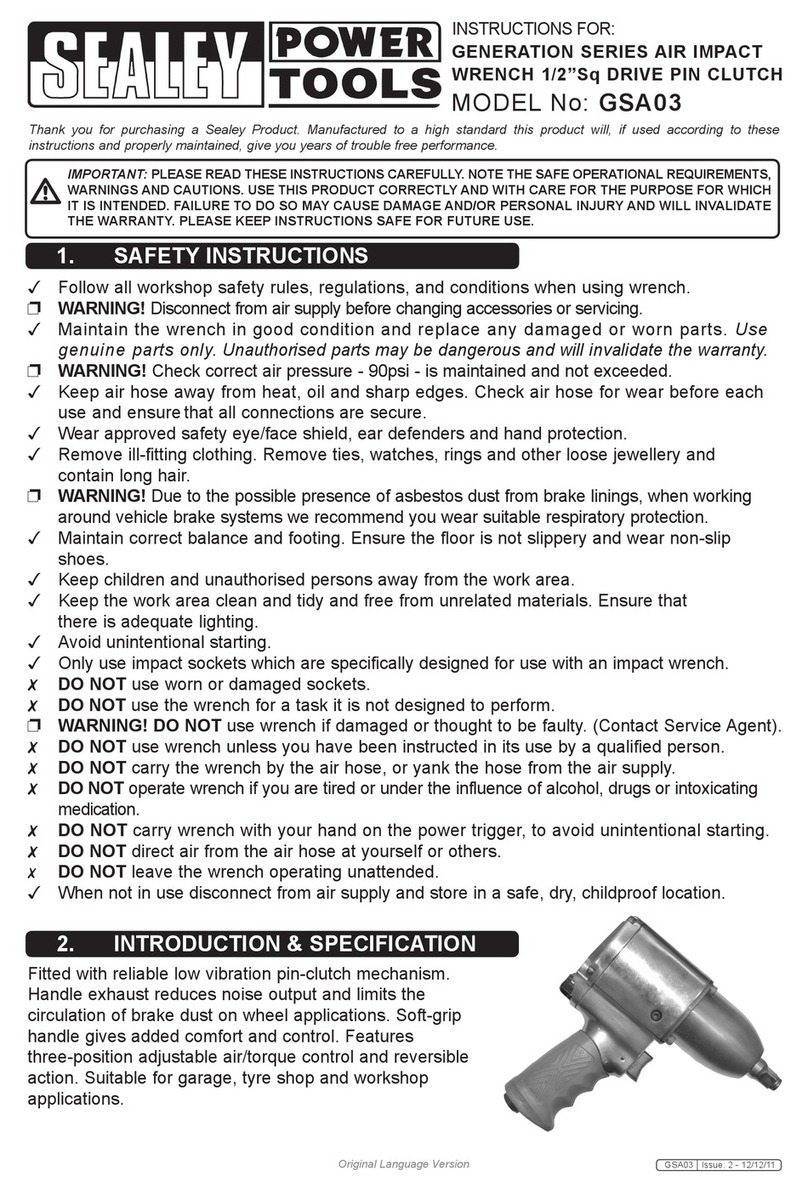

3.1.2 Check the timing positions of the camshafts – each camshaft

has a rectangular section at the rear which has a curved edge

on top and a straight edge on the bottom. With the engine in the

correct TDC engine timing position, the curved edge of the

rectangles, on both camshafts, will be uppermost (g.2).

An additional guide to correct camshaft position, using the

exhaust camshaft, is that in the correct TDC engine timing

position, the recesses in the sections of the exhaust camshaft

between the lobes, will be pointing towards the exhaust

manifold(g.3).

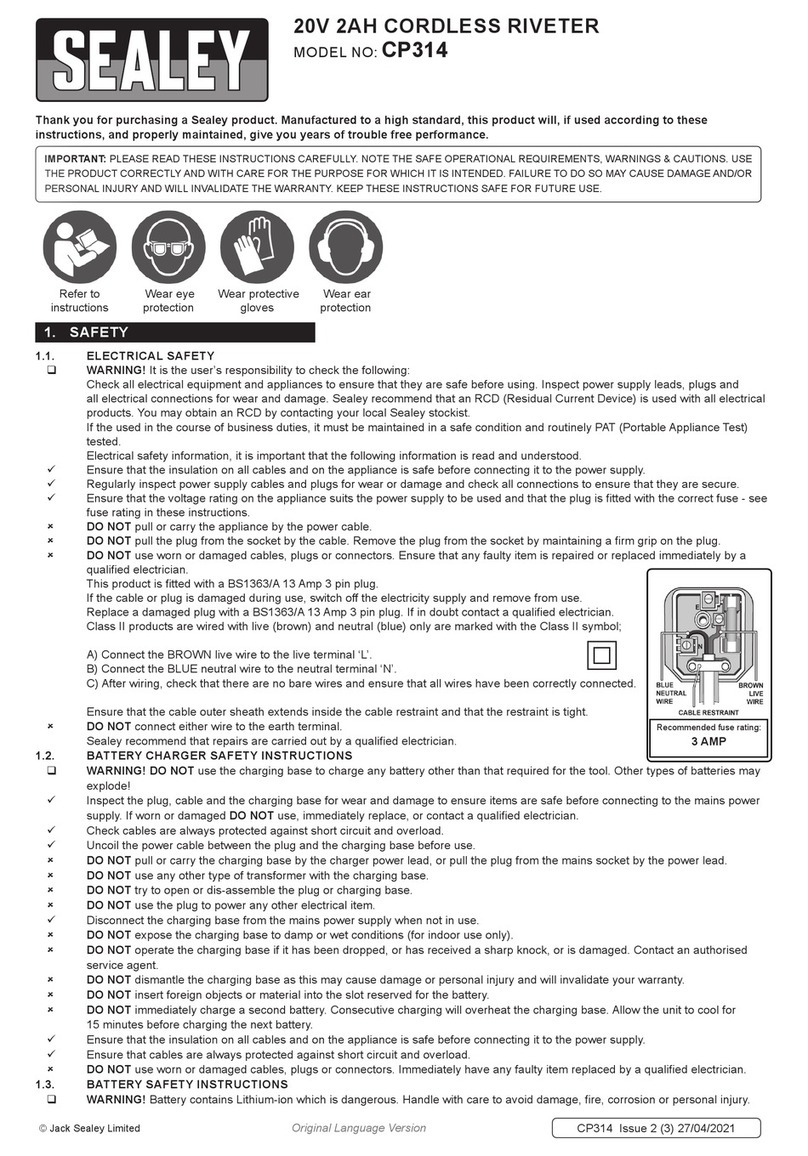

3.2 VS4801 Flywheel TDC Locking Pin

3.2.1 Insert VS4801 Flywheel TDC Locking Pin through the datum

hole, which is located underneath the starter motor, and into the

timingholeintheywheel(g.4).

NOTE:Thedatumholecanbedifculttolocateandmaybe

constricted by dirt/corrosion.

IMPORTANT: On Automatic Transmissions – there is a much

largerholeintheywheelveryneartothetimingholeand

checks are required to ensure that this hole has not been

selected in error. With VS4801 Locking Pin inserted, check that

the engine will not rotate back and forth. Use a wrench on the

crankshaft pulley bolt to rotate the engine.

VANOS Units:

IMPORTANT: If the VANOS Unit has ‘locked’ correctly, the

camshaft will not turn. If the VANOS Units cannot be locked to

the camshafts, it is likely they are faulty, and must be replaced –

refer to Removing and Installing VANOS Units.

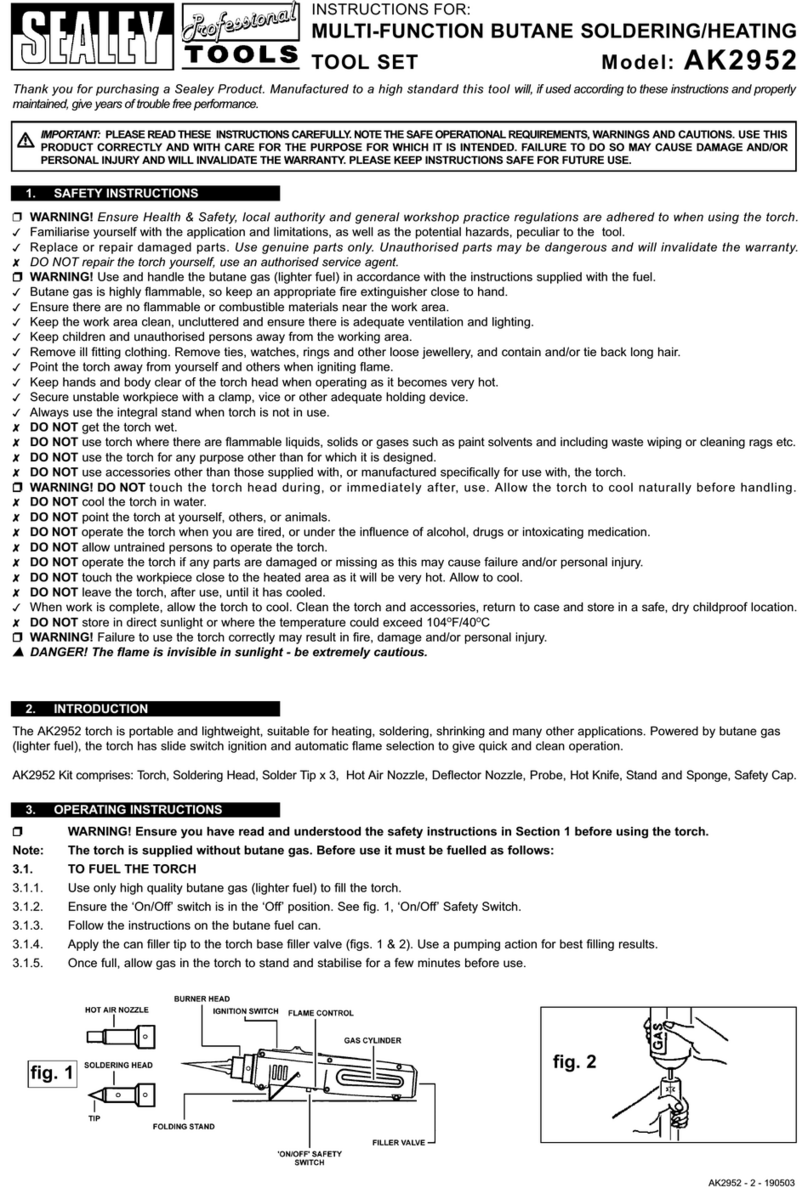

3.3 VS4868 Camshaft Setting Plate Assembly

(comprises VS4868-1, VS4868-2 & VS4805-3)

3. INSTRUCTIONS

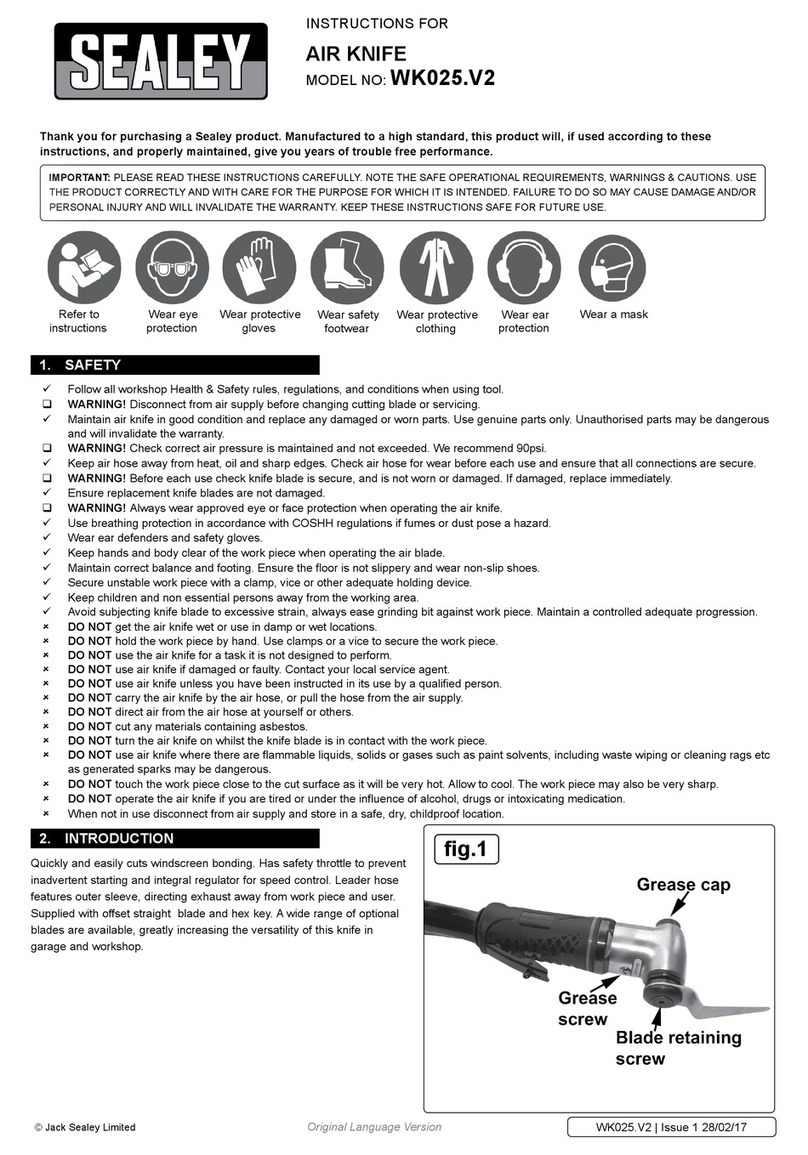

g.1

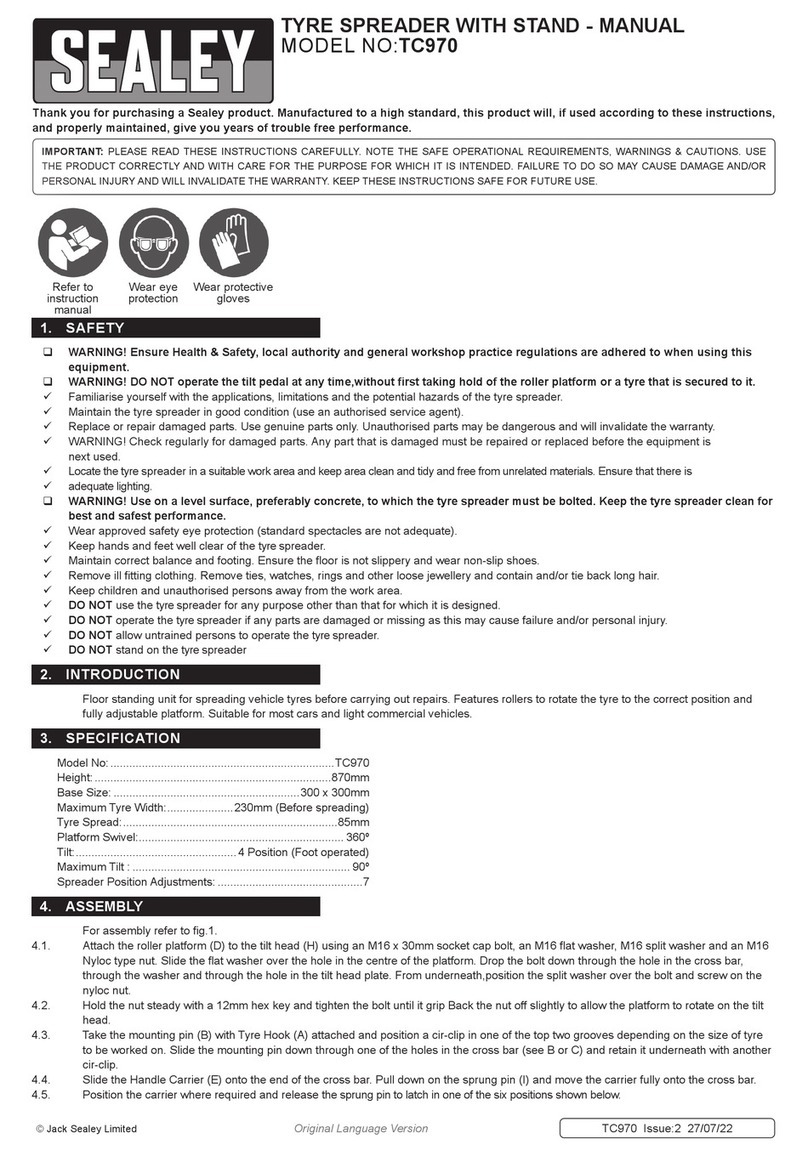

g.3

g.4

g.2

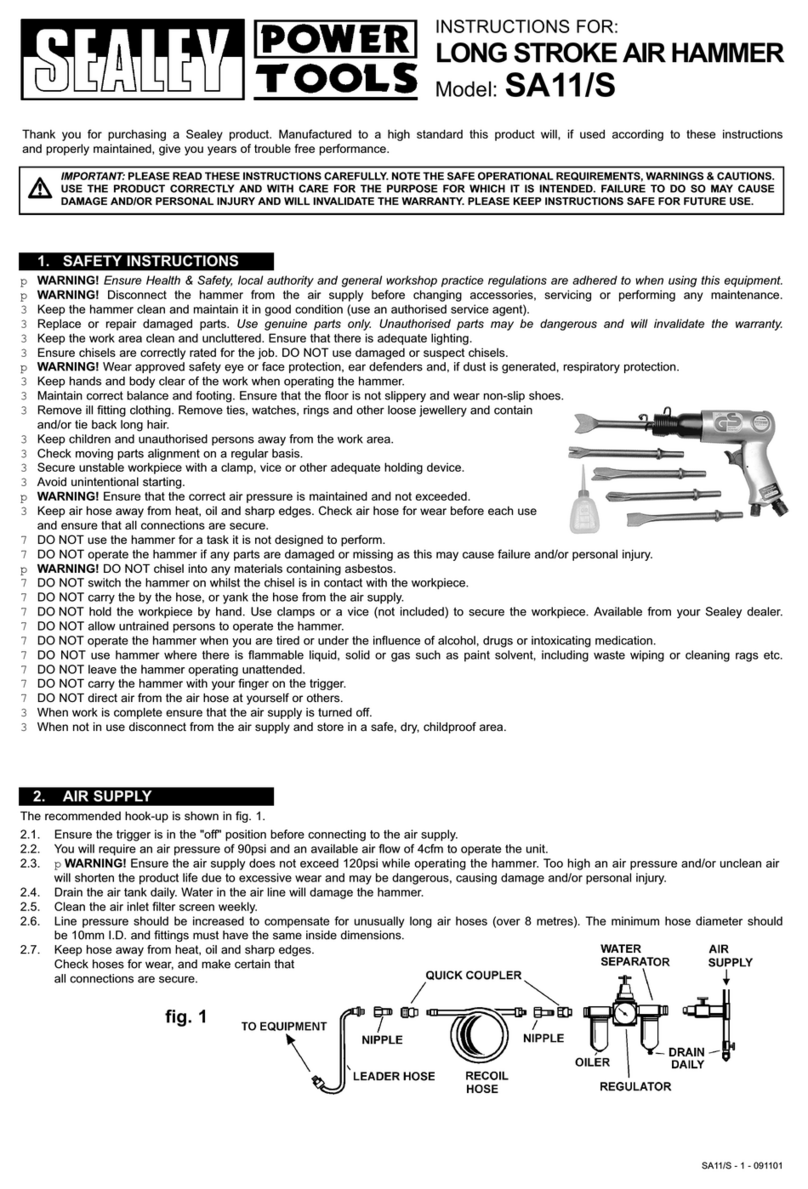

g.5

3.3.1 Place VS4868-1 Camshaft

Setting Plate on to the

rectangular section at the rear of

the INLET camshaft, and ensure

the Plate rests fully on the

surface of the cylinder head.

(Donotinsertxingbolts)

If timing is correct, VS4868-1

Plate should rest on the cylinder

head without any gap, or at most,

raised 0.5mm. to the exhaust

sideonly(g.5).

VS4870 Issue No: 1 - 07/04/09