4. INSTALLATION

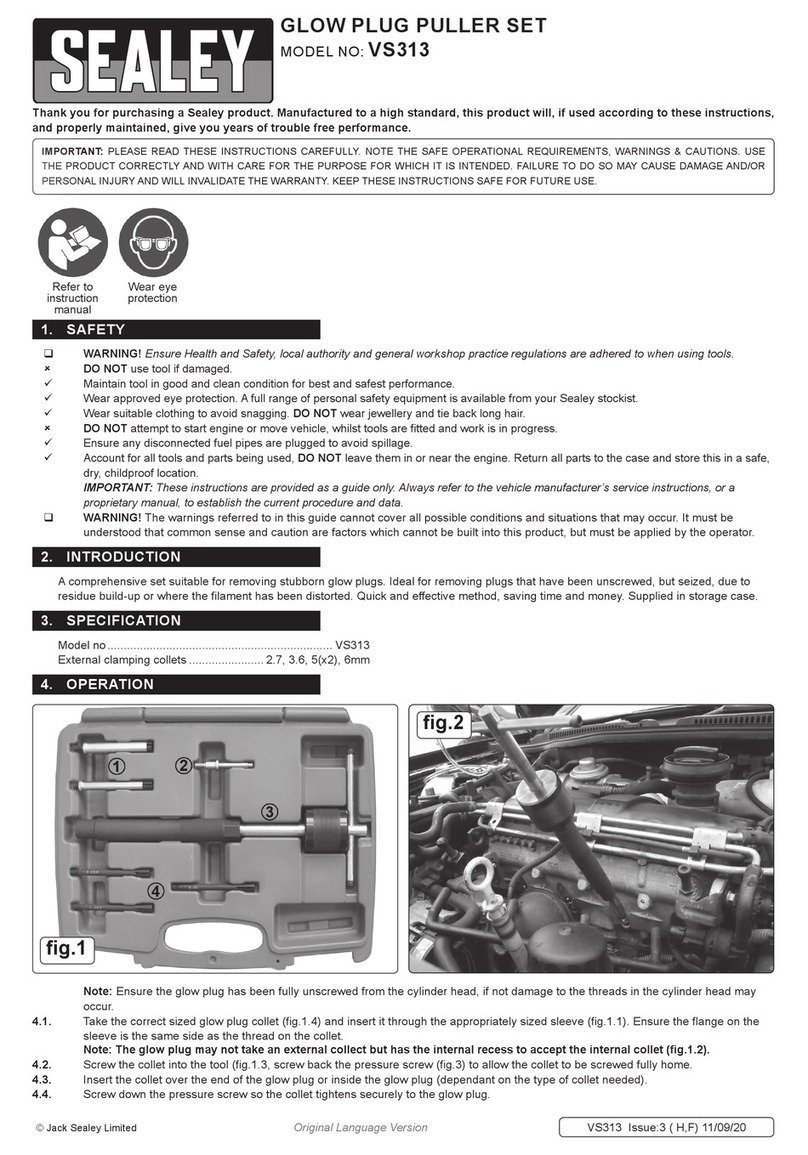

4.1. SETTING UP THE GREASE GUN HEAD (g.1)

Note: Use P.T.F.E. tape while connecting extension pipe to the grease gun head and grease coupler to the extension.

4.1.1. Connect the extension to the outlet of grease gun head.

4.1.2. Thread tighten the grease coupler to other end of extension.

4.1.3. All connections should be tight.

NOTE: Grease or empty cartridge in barrel is under pressure from the internal spring, Be alert when removing head of the barrel.

4.2. GREASE GUN LOADING

●Unscrewbarrelanticlockwise.

●Pullbackplungerrodfullyandlockoutwiththetab(exceptwhenSuctionLoading).

4.2.1. Cartridge Loading

●Removeplasticcapfromendofgreaseguncartridge,insertintobarrelofgreasegun.

●Removesealfromgreaseguncartridgeandscrewgreasegunheadbackontothebarrel.

●Depressthebleedvalve(fig.1).

●Releasetheplungerrodusingitstab,forcetherodoutandinafewtimestoejectairtrappedinthegrease,fromthebleedvalve.

When grease comes out of the valve the air has been discharged.

●Pumpthegreasegunhandleuntilgreaseflowscontinuously.Ifitdoesnot,depressthebleedvalveagainandusetheplungerrodto

expel the trapped air.

●ConnectgreasegunextensionpipeandcouplerontogreasegunoutletusingPTFEtape,DO NOT over tighten.

4.2.2. Suction Loading

●Putopenendofgreasebarrelintogreasecontainertoadepthof50mm.

●Slowlypullbacktheplungerrodtopullthegreaseintothebarrel.Locktherodwiththetab.

●Screwgreasegunheadbackontothebarrel,depressthebleedvalve(g.1).

●ConnectgreasegunextensionpipeandcouplerontogreasegunoutletusingPTFEtape,DO NOT over tighten, as it will fracture.

●Releasetheplungerrodusingitstab,forceitoutandinafewtimestoejectairtrappedinthegrease,fromthebleedvalve.When

grease comes out of the bleed valve the air has been discharged.

●Pumpthegreasegunhandle2/3timesuntilgreaseowscontinuously.Ifitdoesnotdepressthebleedvalveandusetheplungerrod

to expel the trapped air.

Bulk Loading

●Fullydrawbacktheplungerrodhandleandlockintoplace

●Removethegreasegunheadfromthegreasegunbarrelbyturningitcounterclockwise.

●Fillthegreasegunbarrelwithgreaseusingaspatula.

●Reassemblethegreasegunheadtothegreasegunbarrelbyturningitclockwise.

●ConnectgreasegunextensionpipeandcouplerontogreasegunoutletusingPTFEtape,DO NOT over tighten, as it will fracture.

●Depressthebleedvalve.

●Releasetheplungerrodusingitstab,forceitoutandinafewtimestoejectairtrappedinthegrease,fromthebleedvalve.When

grease comes out of the bleed valve the air has been discharged.

●Pumpthegreasegunhandleuntilgreaseowscontinuously.Ifitdoesnotdepresstheplungerrodtabandusetheplungerrodto

expel the trapped air.

●ConnectgreasegunextensionpipeandcouplerontogreasegunoutletusingPTFEtape,DO NOT over tighten.

4.3. USING GREASE GUN (g.3)

4.3.1. Selecttherequiredstrokebyreleasingthetriggeronthehandle(g.1).

4.3.2. Thecouplerhasjawswhichsnapontoagreasenipple.Pushthecouplerstraightontothenippletoformagoodt.

4.3.3. Operate the grease gun as square onto the nipple as possible.

4.3.4. Oncenishedtiltthecouplertwistandpullito.

WARNING! DO NOT try to pull the coupler off straight.

5. MAINTENANCE

Grease gun and extension should be kept clean and checked for damage before each use.

fig.3

© Jack Sealey Limited Original Language Version AK4402.V2Issue:103/07/23