20V SV20 SERIES CORDLESS GREASE GUN-

BODY ONLY

MODEL NO: CP20VGRG

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURYAND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

Refer to

instruction

manual

CP20VGRG Issue:1 06/10/22

Original Language Version

© Jack Sealey Limited

Wear eye

protection

1. INTRODUCTION

9Maintain the grease gun and battery in good condition. Check moving parts alignment on a regular basis.

9Replace or repair damaged parts. Use an authorised service agent and recommended parts only. Unauthorised parts may be

dangerous and will invalidate the warranty.

9Ensure the grease gun is switched o before installing the battery pack.

9Ensure battery pack is correctly inserted into the drill handle and latched in place before attempting to switch on the grease gun.

9Keep the grease gun and charger clean for best and safest performance.

9Remove ill tting clothing. Remove ties, watches, rings and other loose jewellery and contain long hair.

9Avoid unintentional starting.

9Wear approved safety eye protection (standard spectacles are not adequate).

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non-skid shoes.

9Wear appropriate protective clothing. When handling lubricants refer to manufacturer’s instructions and conform to local regulations.

9Be aware that this grease gun does not need to be plugged into the mains power.

9Keep the switch in the off position until the grease gun is required for use.

9Keep children and unauthorised persons away from the working area.

8DO NOT use the grease gun where there are ammable liquids, solids or gases, such as paint solvents, etc.

8DO NOT allow children to operate the grease gun.

8DO NOT allow unauthorised persons to operate the gun.

8DO NOT operate the grease gun if any parts are missing as this may cause failure and/or personal injury.

8DO NOT hold unsecured work piece in your hand.

8WARNING! Disengage the grease gun from the battery before changing accessories, servicing or performing and maintenance.

9Maintain gun in good condition (use an authorised service agent).

9Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9Use the gun in a suitable working area. Keep area clean and tidy and free from unrelated materials and ensure there is adequate lighting.

9Dispose of waste grease in accordance with local authority regulations.

9When not in use ensure the battery is removed.

WARNING! DO NOT tamper with or open pump unit. Doing so will invalidate your warranty.

8DO NOT point grease gun at yourself or other persons or animals.

8DO NOT pull the grease gun unit by the hose.

8When not in use, clean the unit and store in a dry, safe, childproof area.

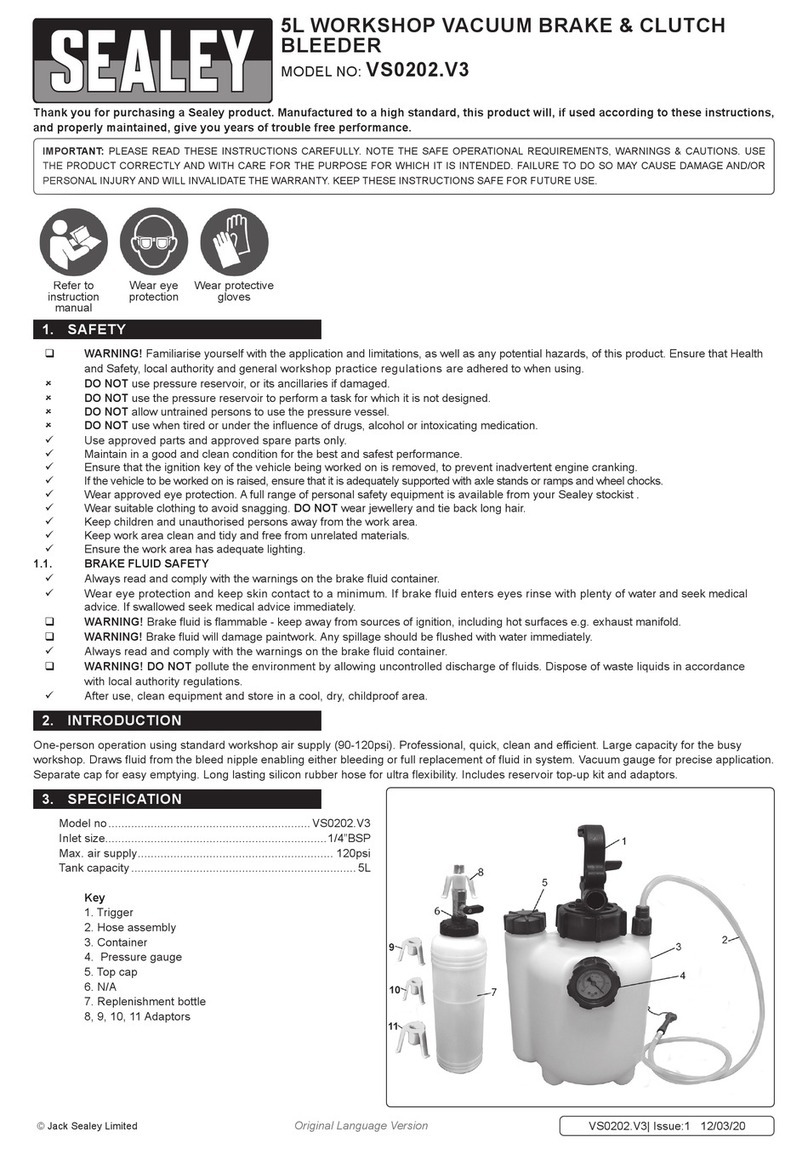

2. INTRODUCTION

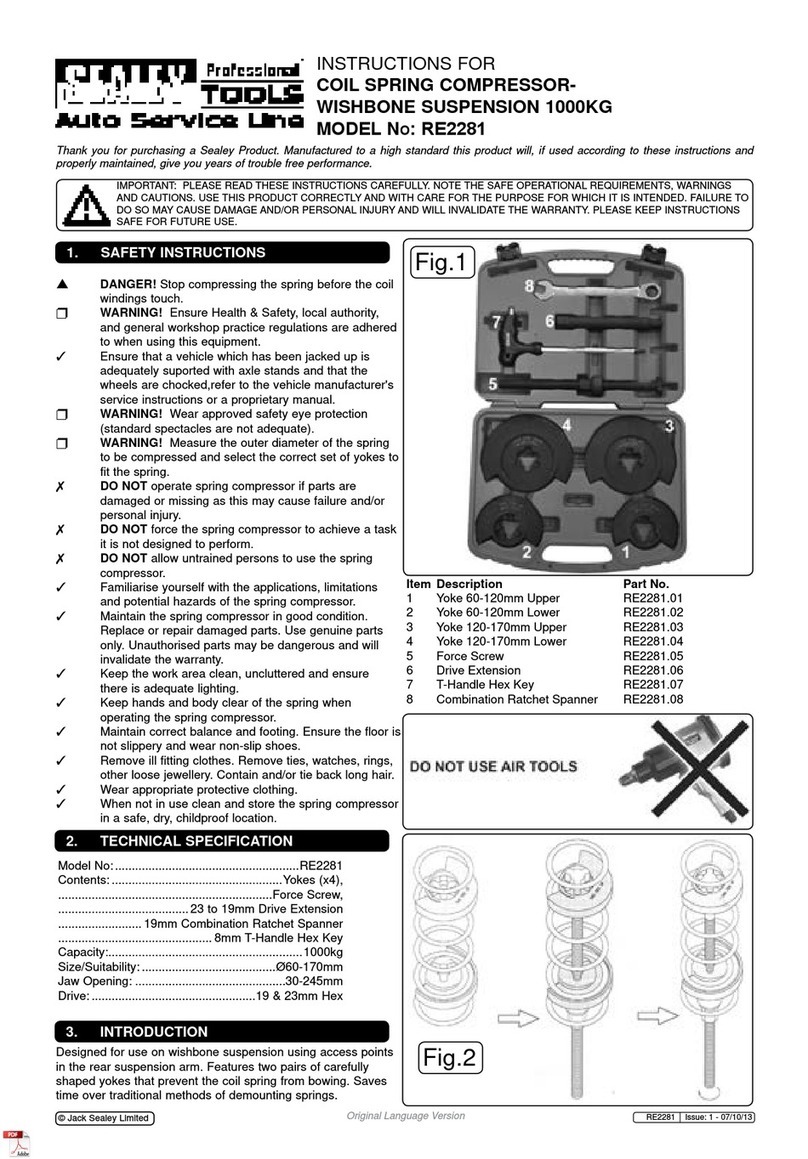

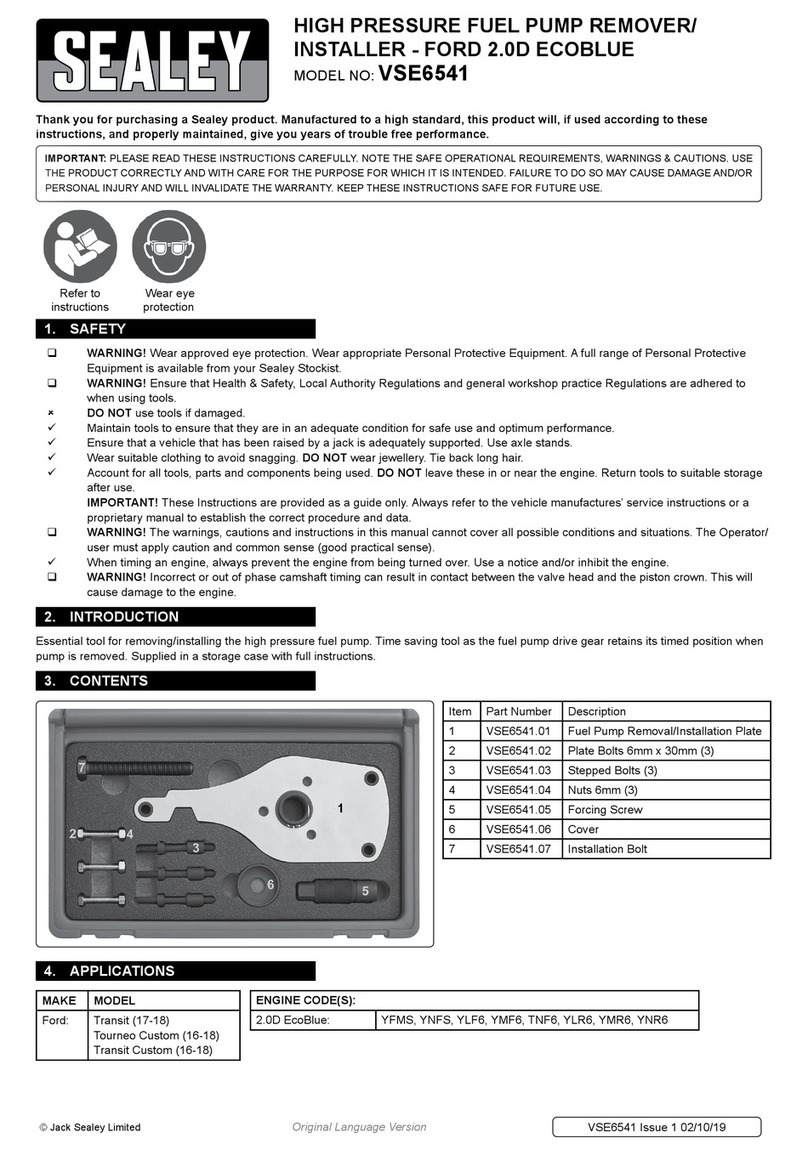

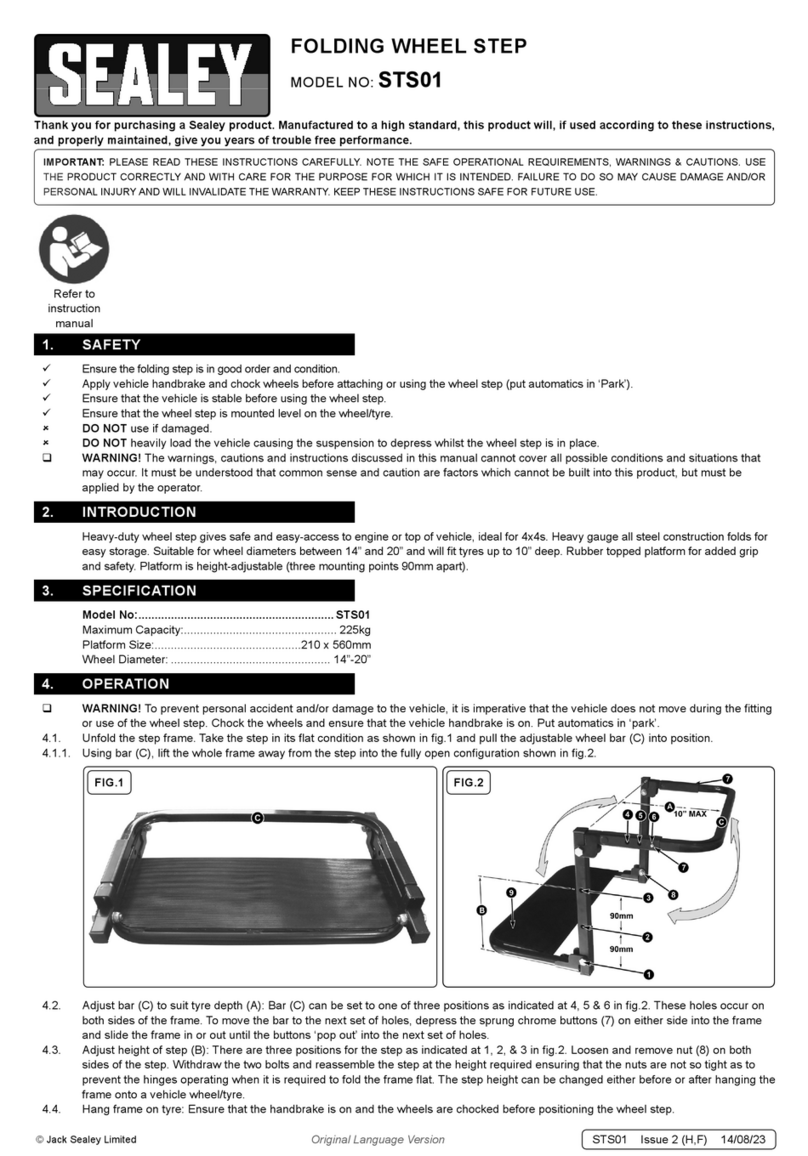

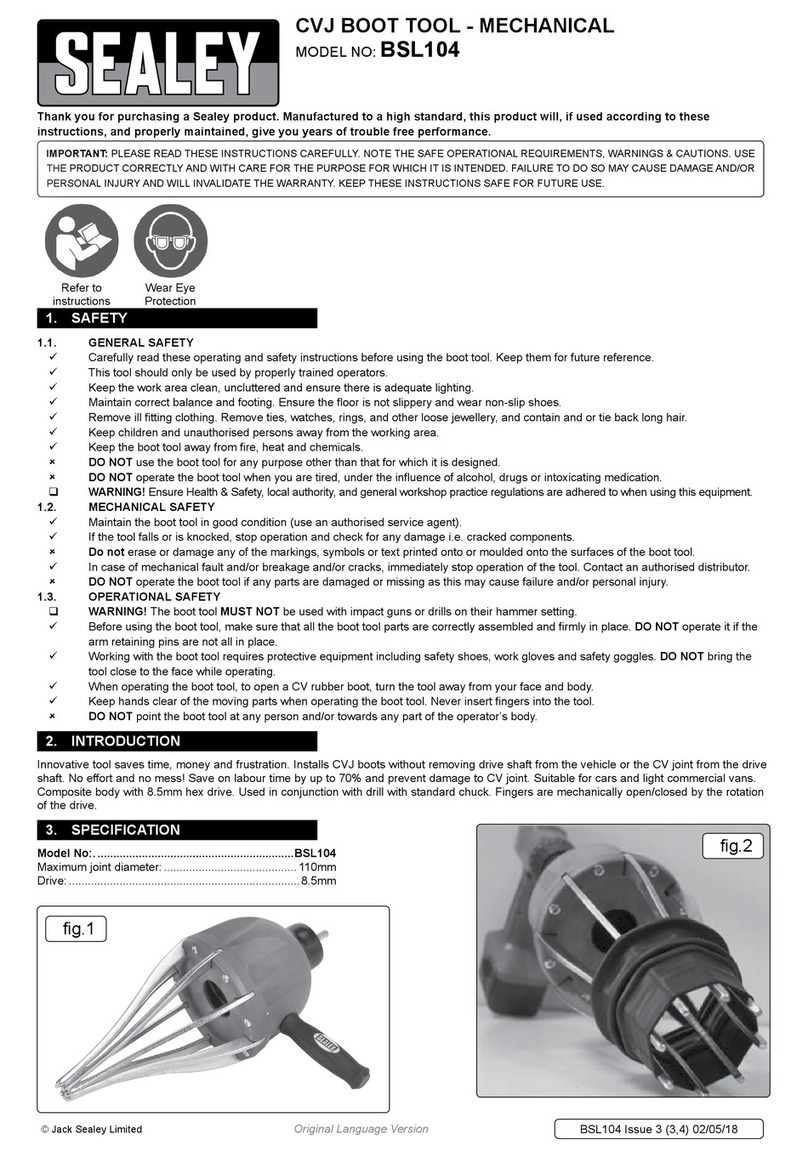

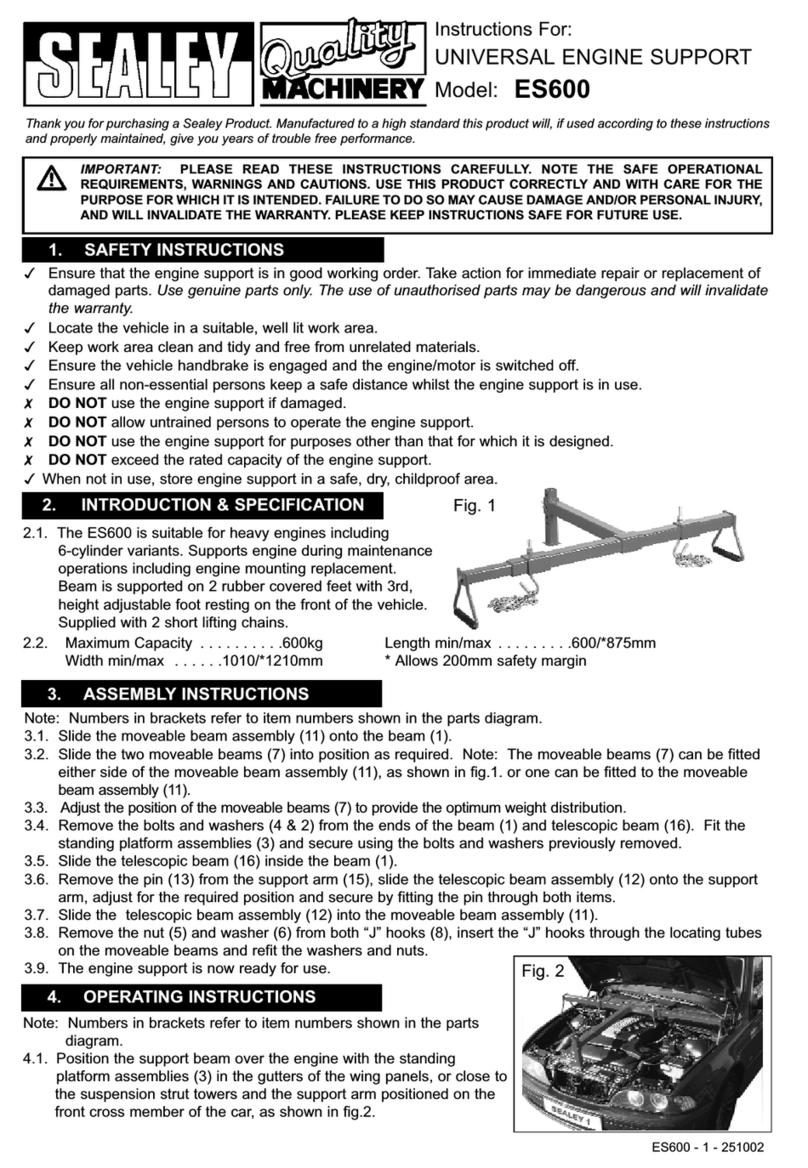

High power, professional, cordless grease gun, developing 8000psi. Ideal for in-eld lubrication where power and speed are required.

Suitable for screw-type and standard 400g cartridges, manual or bulk lling. Features LCD battery condition indicator, air bleed and

heavy-duty aluminium pressure head. Requires compatible 20V battery and mains charger, sold separately. SPECIFICATION

3. SPECFICATION

Model No:.....................................................................CP20VGRG

Battery ...........................................................................Compatible with CP20VBP2, CP20VBP4, CP20VBP6

Flow Rate:......................................................................100g/min

Hose Length:..................................................................700mm

Mains charger ................................................................CP20VMC

Pressure:.........................................................................8000psi

Wear protective

gloves