Seiko 7T82A Quick start guide

Other Seiko Watch manuals

Seiko

Seiko Astron 7X52 Instruction manual

Seiko

Seiko Alba User manual

Seiko

Seiko SSC141P1 User manual

Seiko

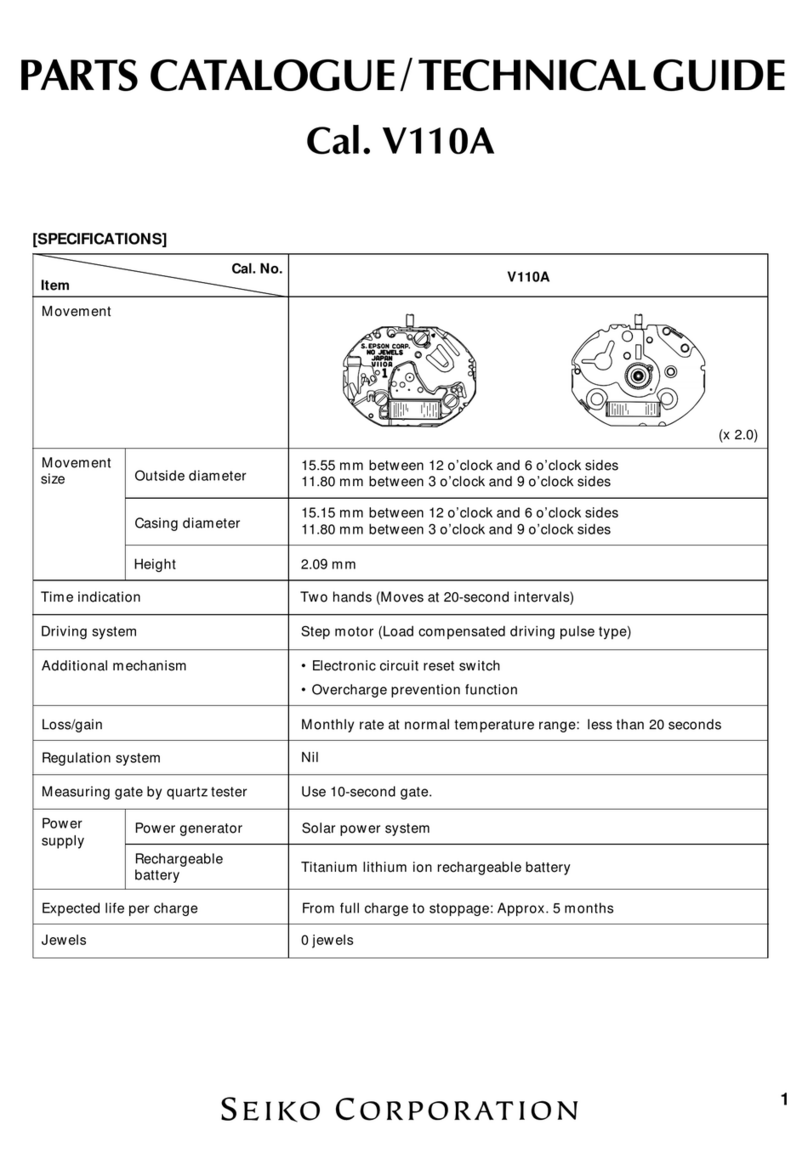

Seiko V110A Installer manual

Seiko

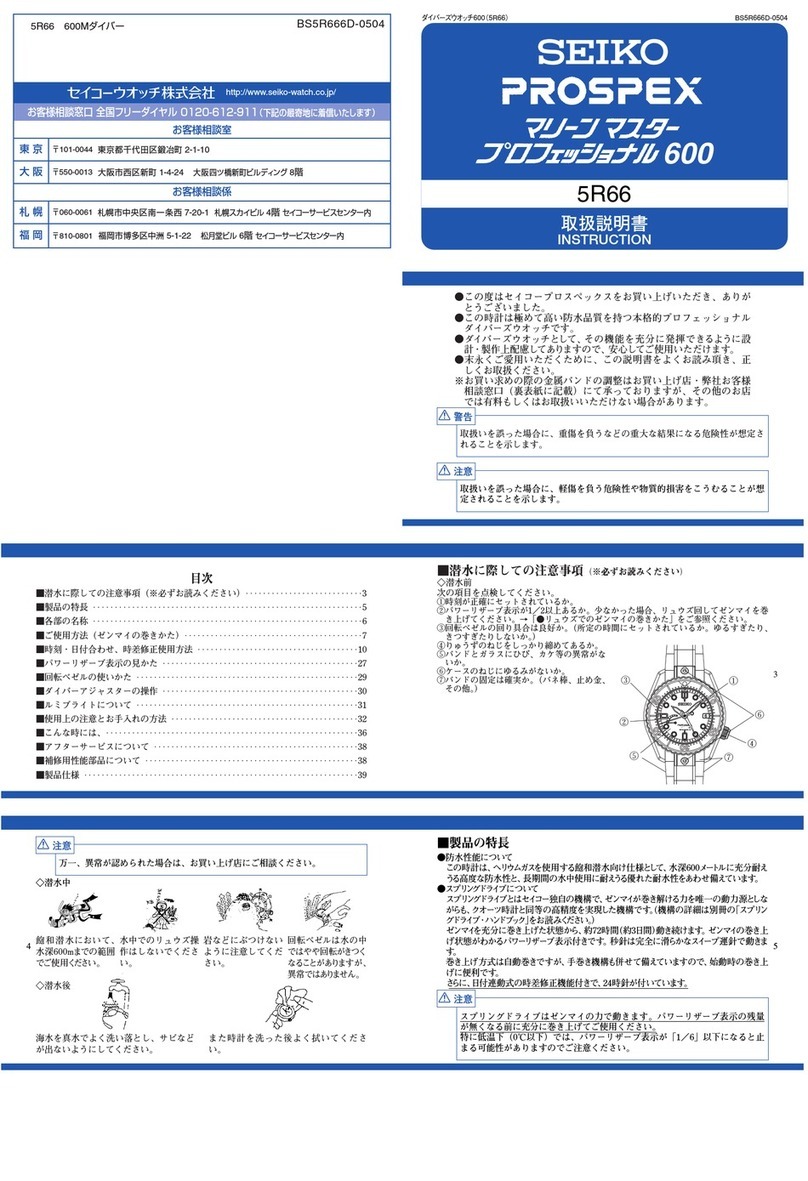

Seiko 5R66 User manual

Seiko

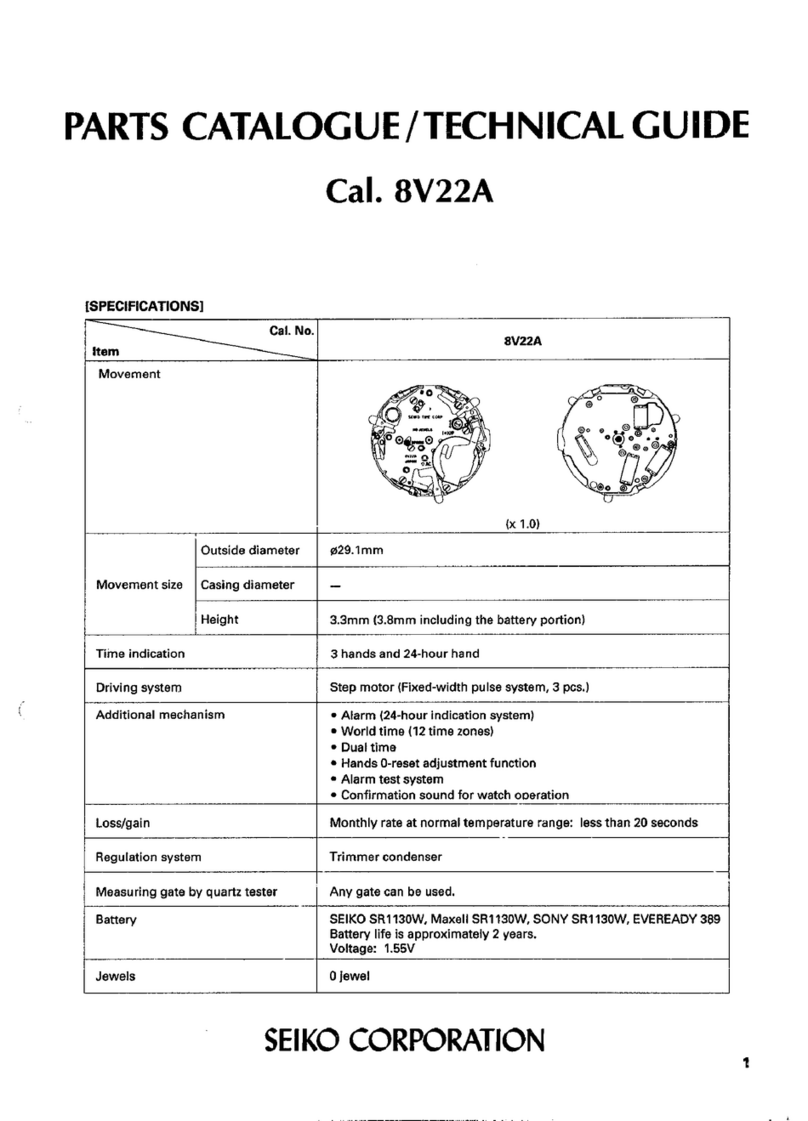

Seiko 8V22A Installer manual

Seiko

Seiko SRG019P2 User manual

Seiko

Seiko 4R35A Quick start guide

Seiko

Seiko SSB367 User manual

Seiko

Seiko STOPWATCH S143 User manual

Seiko

Seiko S141 User manual

Seiko

Seiko Issey Miyake NE15 User manual

Seiko

Seiko 8F35 User manual

Seiko

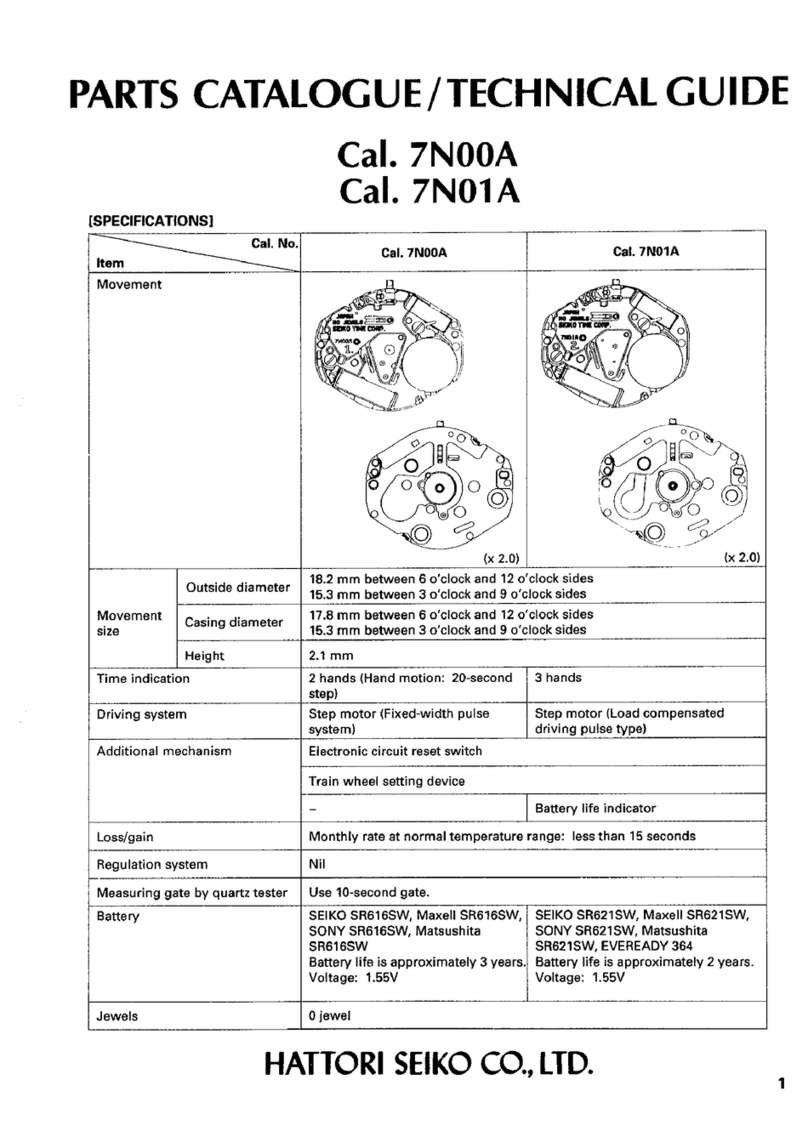

Seiko 7N00A Installer manual

Seiko

Seiko G300 User manual

Seiko

Seiko C-26 User manual

Seiko

Seiko H023 User manual

Seiko

Seiko Grand 3F81 User manual

Seiko

Seiko ASTRON 8X42 GPS SOLAR User manual

Seiko

Seiko SSJ013J1 User manual