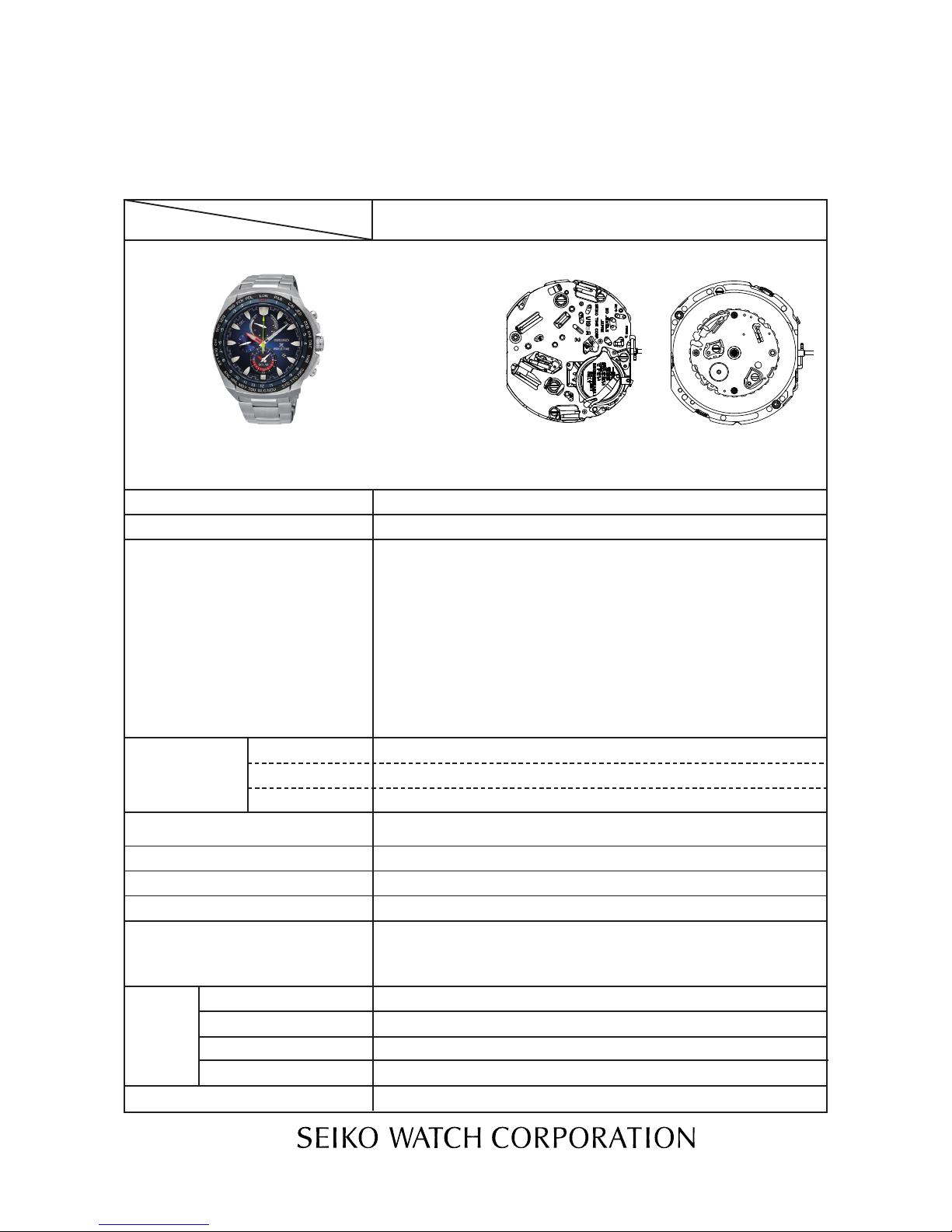

FEATURES

The Cal. V195A is a solar alarm chronograph epuipped with a calendar function.

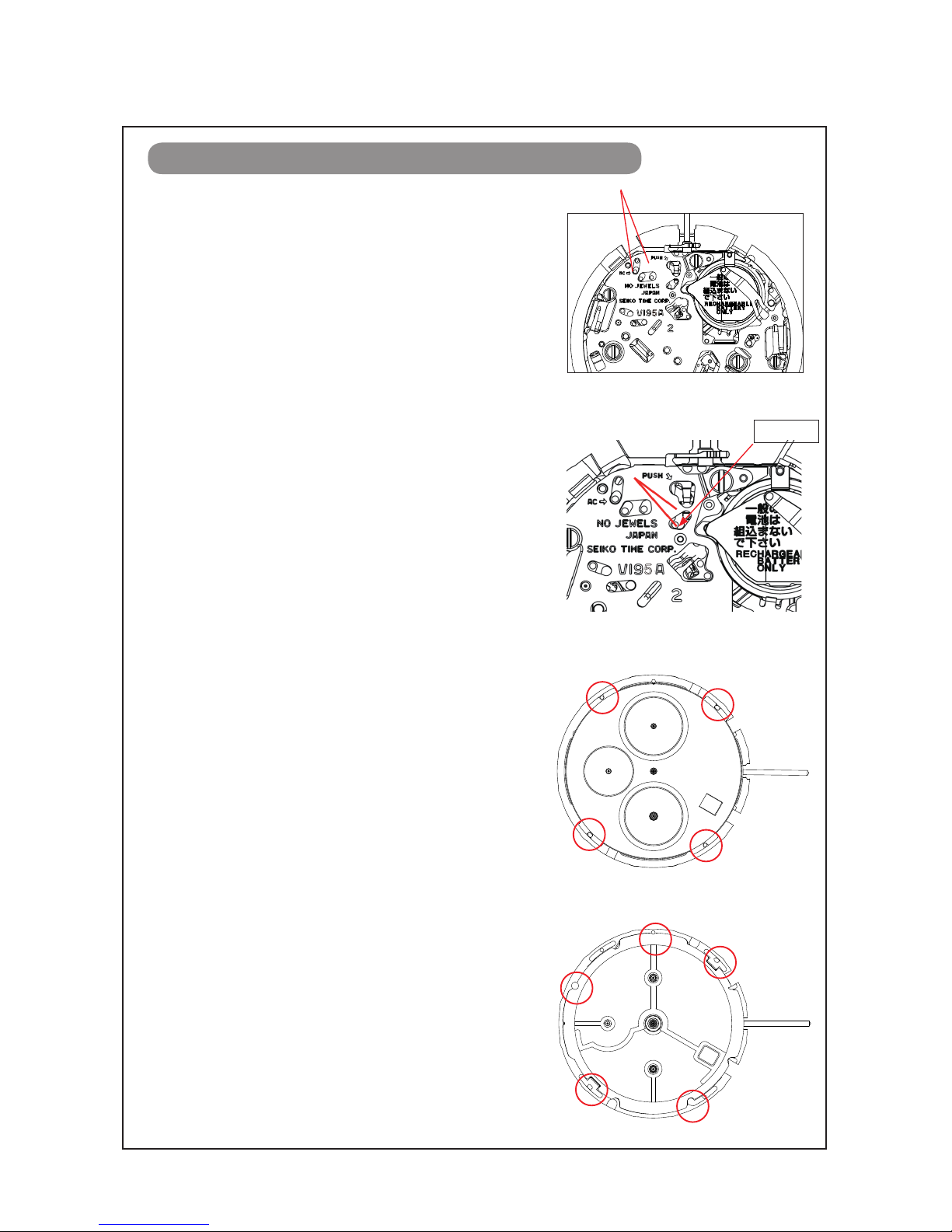

l Solar power generation system

The watch operates while charging electricity by converting light received on the dial to

electrical energy. It lasts for 6 months after full charge.

l Energy depletion forewarning function

When the energy stored in the rechargeable battery is reduced to an extremely low level, the

second hand starts moving at 2-second intervals instead of the normal 1-second intervals.

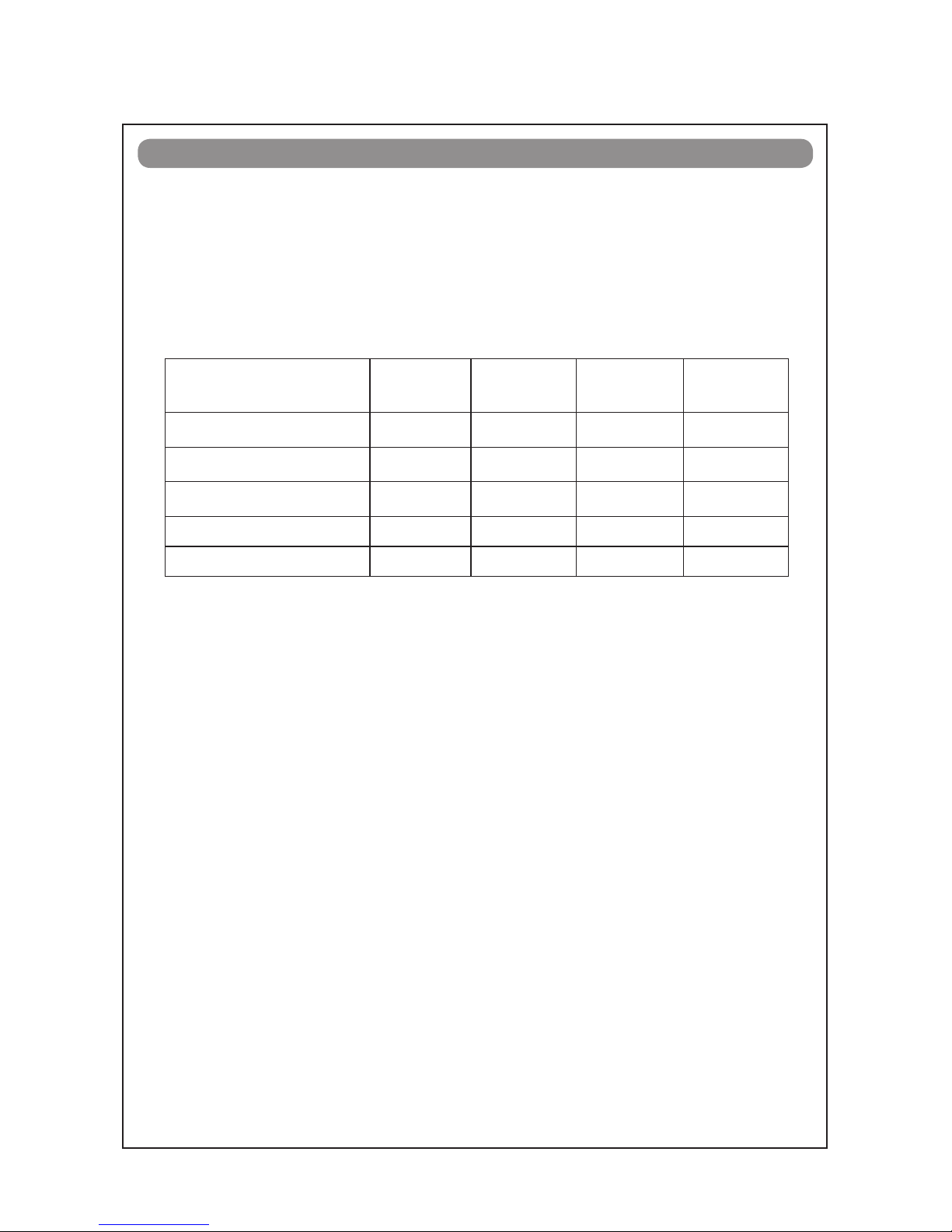

l Guideline of charging time

Environment/Light source Illumination

(lux)

Time required

for full charge

Time required

for steady

operation

Time to charge

1 day of power

General offices/ Fluorescent

Light

700 -60 hours 150 minutes

30W 20cm/Fluorescent light 3,000 110 hours 13 hours 33 minutes

30W 3cm/ Fluorescent light 10,000 30 hours 3.5 hours 9 minutes

Cloudy weather/Sunlight 10,000 30 hours 3.5 hours 9 minutes

Fair weather/Sunlight 100,000 5 hours 0.6 hours 2 minutes

The above table provides only a general guideline.

It is recommended that the watch be charged for as long as the charging time according to the

column "Time required for steady operation" in this table in order to assure the stable movement

of the watch.

l Caution for charging

When charging the watch, do not place it too close to a photo flash light, spotlight, incandescent

light or other light sources as the watch temperature will become extremely high, causing damage

to the parts inside the watch.

When exposing the watch to sunlight to charge it, do not leave it on the dashboard of a car, etc.

for a long time, as the watch temperature becomes extremely high.

While charging the watch, make sure the watch temperature does not exceed 60 °C.