Senco FinishPro XtremePro 25 XP User manual

Other Senco Nail Gun manuals

Senco

Senco FN65DA User manual

Senco

Senco Cordless Finish 25 User manual

Senco

Senco AirFree 25 User manual

Senco

Senco SPBN18XP User manual

Senco

Senco F-16A User manual

Senco

Senco TN41P1P User manual

Senco

Senco DFP User manual

Senco

Senco AirFree 25 User manual

Senco

Senco FramePro 750XL User manual

Senco

Senco AirFree 32 User manual

Senco

Senco A10 User manual

Senco

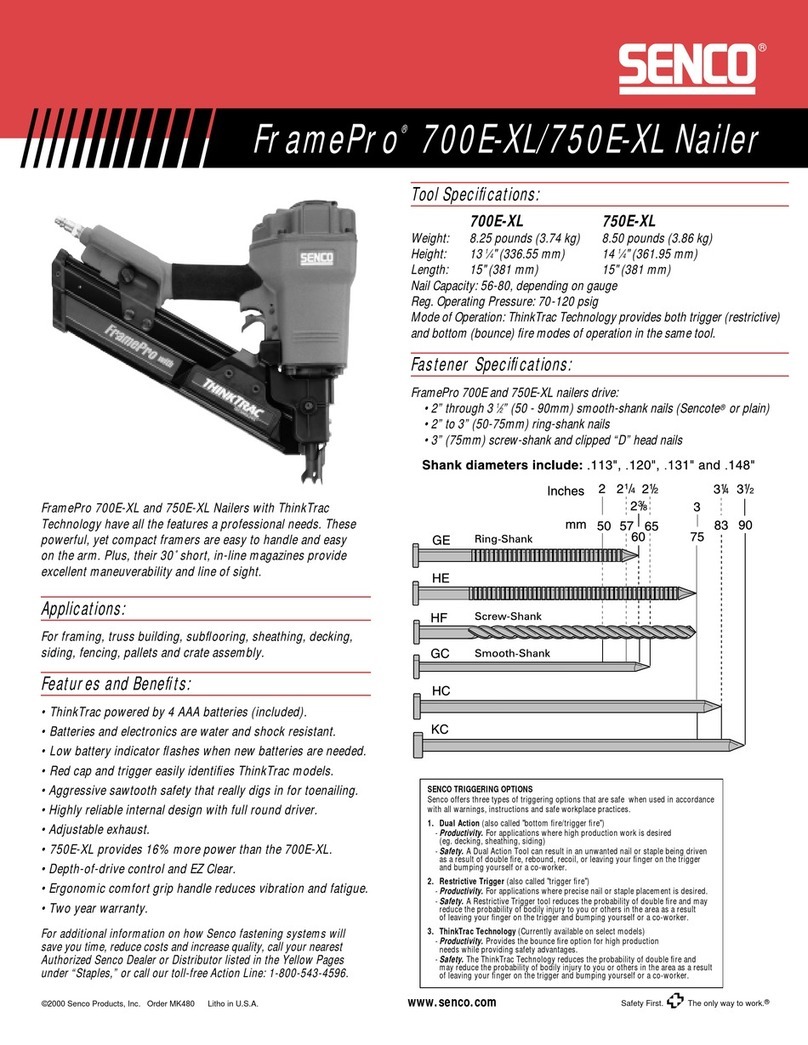

Senco FramePro 700E-XL User manual

Senco

Senco ISANTA GT60i-NN User manual

Senco

Senco SN71P1 User manual

Senco

Senco FramePro 700XL User manual

Senco

Senco GT50i-N/O User manual

Senco

Senco Pallet Pro User manual

Senco

Senco FinishPro 32 User manual

Senco

Senco PalletPro 57 User manual

Senco

Senco FN81T1 User manual

Popular Nail Gun manuals by other brands

Performance Tool

Performance Tool M643 owner's manual

Hitachi

Hitachi VH650 - Fencing Nailer, Full Head instruction manual

Parkside

Parkside PET 25 B1 Operation and safety notes

Grizzly

Grizzly G1847 instruction manual

Ryobi

Ryobi R18N18G Original instructions

Black & Decker

Black & Decker 492848-00 instruction manual