GENERAL SERVICE, REPAIR, OR

RETURNS

Before sending any item to Server Products for service,

repair, or return, contact Server Products customer service

to request a Return Authorization Number.

Merchandise must be sent to Server Products with this

number.

Merchandise being returned for credit must be in new and

unused condition and not more than 90 days old and will

be subject to a 20% (percent) restocking charge.

Electrical parts (thermostats, heating elements etc.)

are not returnable.

Server Products maintains a fully staffed service

department with highly skilled factory trained personnel.

Service is extremely prompt. Under normal circumstances,

a repaired unit is shipped out the day after it is received.

Labor charges are reasonable.

SERVICE

Contact dealer or Server Products Inc.

customer service department for the following:

ORDERING REPLACEMENT PARTS

Be prepared to give this information:

• MODEL Letters/Name/Numbers

• Part Numbers- P/N

• Series Numbers/Letters

• Part Description

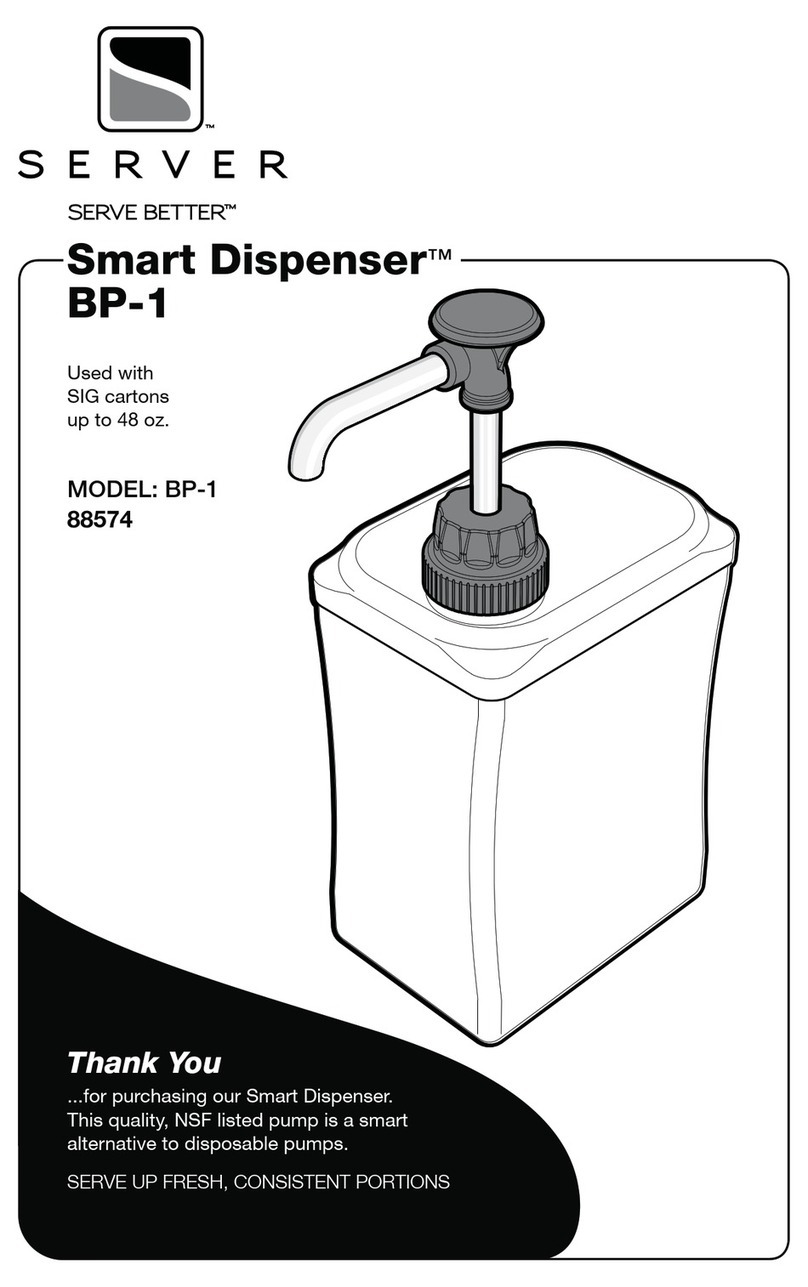

This information and other important data is stamped on

the lid or cylinder of pumps or on the bottom or back side

of every unit.

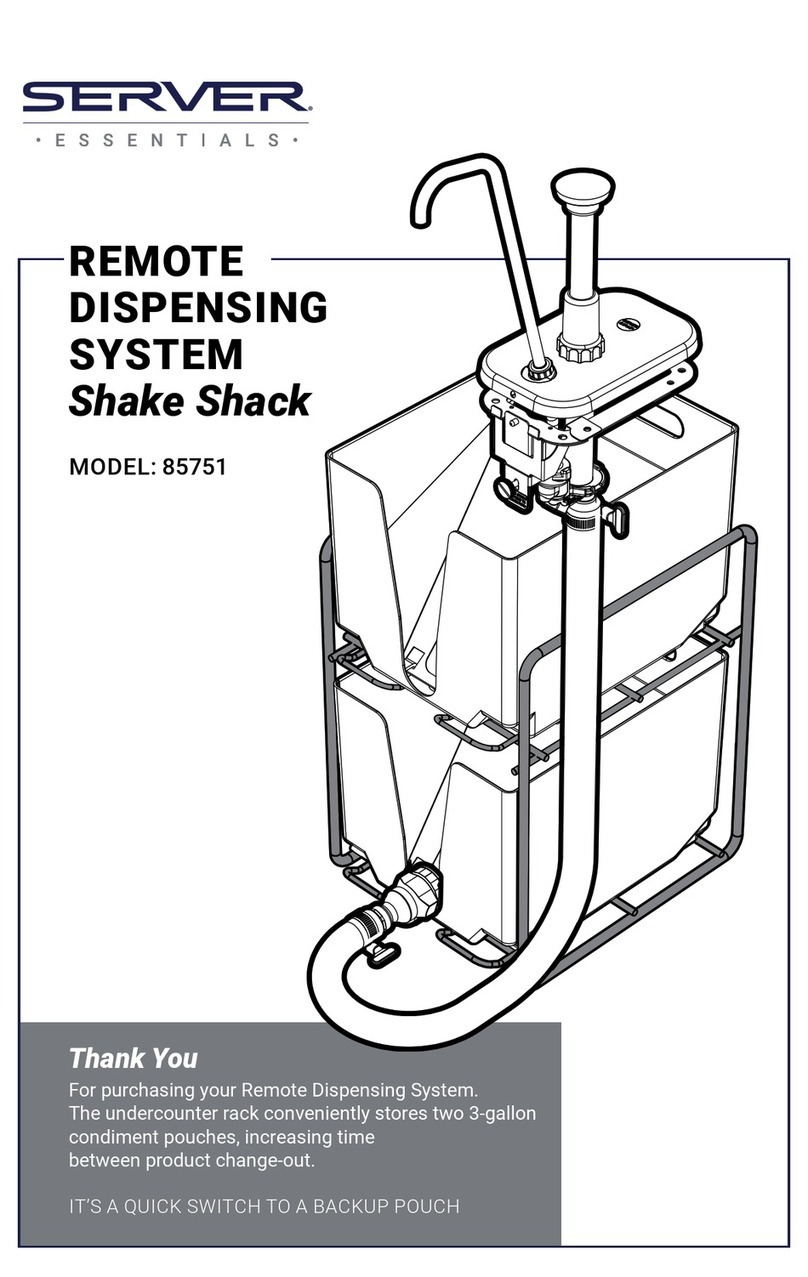

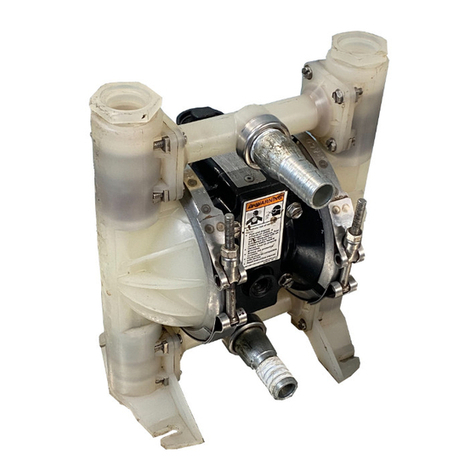

PUMP ASSEMBLY

ALWAYS CLEAN PUMP THOROUGHLY BEFORE EACH USE

AND AFTER USE DAILY. SEE PUMP DISASSEMBLY AND

PUMP CLEANING.

1INSTALL SEAL O-RING INSIDE SEAL.

• Apply food equipment lubricant on seal o-ring.

2INSTALL SEAL ASSEMBLY SECURELY ONTO HEAD

ASSEMBLY PISTON.

• Apply food equipment lubricant inside seal assembly.

• Flared end of seal assembly should be facing away

from piston head.

• If seal is installed incorrectly, product will leak past

seal.

3APPLY A SMALL AMOUNT OF FOOD EQUIPMENT

LUBRICANT INSIDE BOTTOM OF HEAD ASSEMBLY

PISTON. THEN INSTALL PINCH VALVE INTO BOTTOM

END OF HEAD ASSEMBLY PISTON.

• Rotate pinch valve inside head assembly piston

to spread lubricant evenly inside end of head

assembly piston. Then position pinch valve

securely into a sealed position on end of head

assembly piston.

4INSTALL GAGING COLLAR ONTO SIDE OF HEAD

ASSEMBLY PISTON.

5INSTALL SPRING INTO CYLINDER.

6INSTALL CAP BY SECURELY SNAPPING IT ONTO

CYLINDER, PAST THREADING.

7INSTALL LID BY SLIDING LID UP FROM BOTTOM OF

CYLINDER TO ALIGN WITH CAP. SECURE PUMP TO

LID BY TIGHTENING CAP TO LID THREADING.

8 APPLY A SMALL AMOUNT OF FOOD EQUIPMENT

LUBRICANT INSIDE TOP OF CYLINDER AND TO

OUTSIDE SURFACE OF SEAL.

9INSTALL HEAD ASSEMBLY PISTON INTO CYLINDER.

JSLIDE LOCKING COLLAR DOWN ONTO CYLINDER

THREADING AND TIGHTEN TO SECURE HEAD

ASSEMBLY TO CYLINDER.

KPREPARE PUMP FOR USE.

• Operate pump several times until only product,

without air bubbles, is delivered with each stroke

of pump.

TROUBLESHOOTING

FOR PUMP

Pump dispenses little or no product:

• Ensure pinch valve is properly installed into

bottom of head assembly.

• Ensure ball is snapped in place down inside

cylinder.

• Product may be too stiff or contain a solid that

will not pass through pinch valve.

Product oozes out around locking collar:

• Ensure seal is securely installed onto head

assembly piston. Ensure ared edge of seal is

facing down towards bottom of piston.

Pump head assembly does not return to top of stroke

after dispensing product:

• Inspect spring for any damage. If bent or

broken, spring may cause permanent damage

to cylinder. Replace spring if necessary.

Pump drips:

• Clean head assembly discharge tube with

smaller bristled brush.

• Ensure product is not being heated by any

external source(s) causing product to expand

and drip from pump.

Portion control is not consistent:

• Inspect gaging collar for any damage, verify

that it is the correct one, and is installed

properly onto head assembly piston.

• Inspect pinch valve for any damage. Replace if

necessary.

• Ensure ball is snapped in place down inside

cylinder.

Problems with pump operation and/or ow:

• Replace seal if necessary.

• Replace cylinder assembly if necessary.

• Clean pump.

SERVER PRODUCTS

LIMITED WARRANTY

All Server Products equipment is backed by a

two-year limited Warranty against defects in materials and

workmanship. For complete Warranty information go to:

www.server-products.com

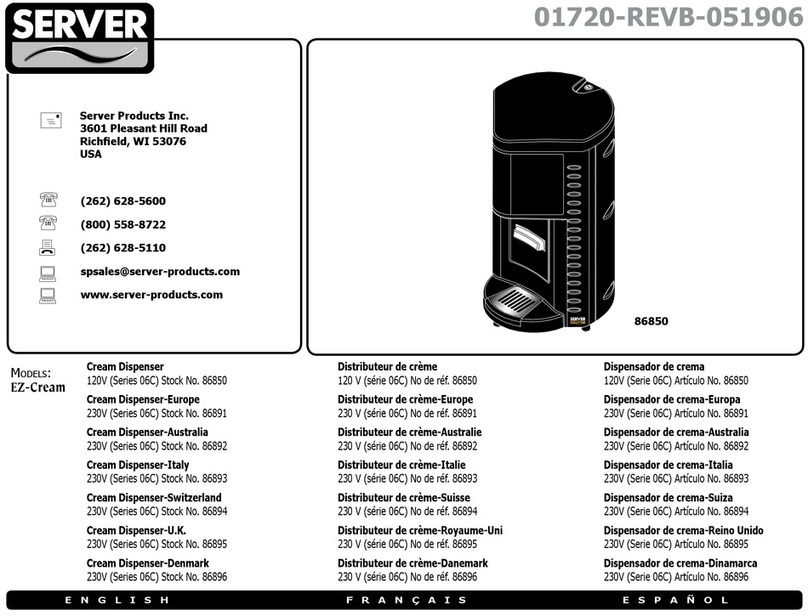

Server Products Inc.

3601 Pleasant Hill Road

Richfield, WI 53076 USA

262.628.5600

800.558.8722

262.628.5110

www.server-products.com

SAFETY GUIDELINES

According to food and safety regulations, most foods must

be stored and/or served at certain temperatures or they

could become hazardous. Check with local food and safety

regulators for specic guidelines.

Be aware of the product you are serving and the

temperature the product is required to maintain.

Server Products, Inc. can not be responsible for the

serving of potentially hazardous product.

NSF International

(National Sanitation Foundation)

lists this pump as: “Not acceptable for

dispensing potentially hazardous foods.”

Stainless steel is one of the best materials for food

serving and storage, but there are many products which

can corrode it. If you notice corrosion beginning on

any stainless steel surface, you may need to change

the cleansing agent, sanitizing agent, or the cleaning

procedures you are using.

• Products containing: acids, alkalines, chlorine,

or salt can corrode stainless steel.

• Sauerkraut and Au Jus sauces corrode stainless steel.

Server Products, Inc. regrets that we can not honor

Warranty claims on stainless steel parts that have

been affected by sauerkraut

or Aus Jus.