Sesamo PIUMA User manual

PIUMA

Automatism

for

swinging

doors

INSTALLATION

INSTRUCTIONS

ffin@'ffi

We thankyou for having chosenthis product.In orderto get the bestperformance

from the device,Sesamo

recommendsthat

youread

and

follow carefullytheinstructionsfor installation

andusecontainedin thismanual.

Do not litter the environmentwith the packingmaterialswhich may be a sourceof hazard

for childrenand

animals.

Theinstallation

mustbecarriedoutby qualified

staffin conformitywith theregulationsin force.

Payparticular

attention

to themessages

containedin thismanual

and

marked

by thedangersymbol.Thesemay

either be wamingsto avoid potentialdamageto the apparatus,

or specificsignalsof potentialhazardfor the

safetyofthetechnician

orother

people

involved.

GENERAi,L

Read

thismanual

carefullybefore

proceeding

to the installation,stalt-upor maintenance

of theapparatus.

This

device

has

beenconceived

to automate

pedestrian

swingingdoors;anyotheruseshallbeconsideredcontraryto

theuseforeseenbythemanufacturer

who cannotbeliablefor damages

to people

orthings.

Beforetheinstallation,

checkthatthedoorto be automatedhasa uniform andfrictionless

openingandclosing

movement.

Checkthat the fixing surfaceis level and smoothso asto avoid deformations

to the baseof the

automatism

andthatit is of asuitablesizefor astable

fixing of theapparatus.Eliminateanyspringdoor-closing

devices

previouslyinstalled.The builder is not liable for anydeformationto the automatedfixture dueto the

inadequatefirmness

of theframe.

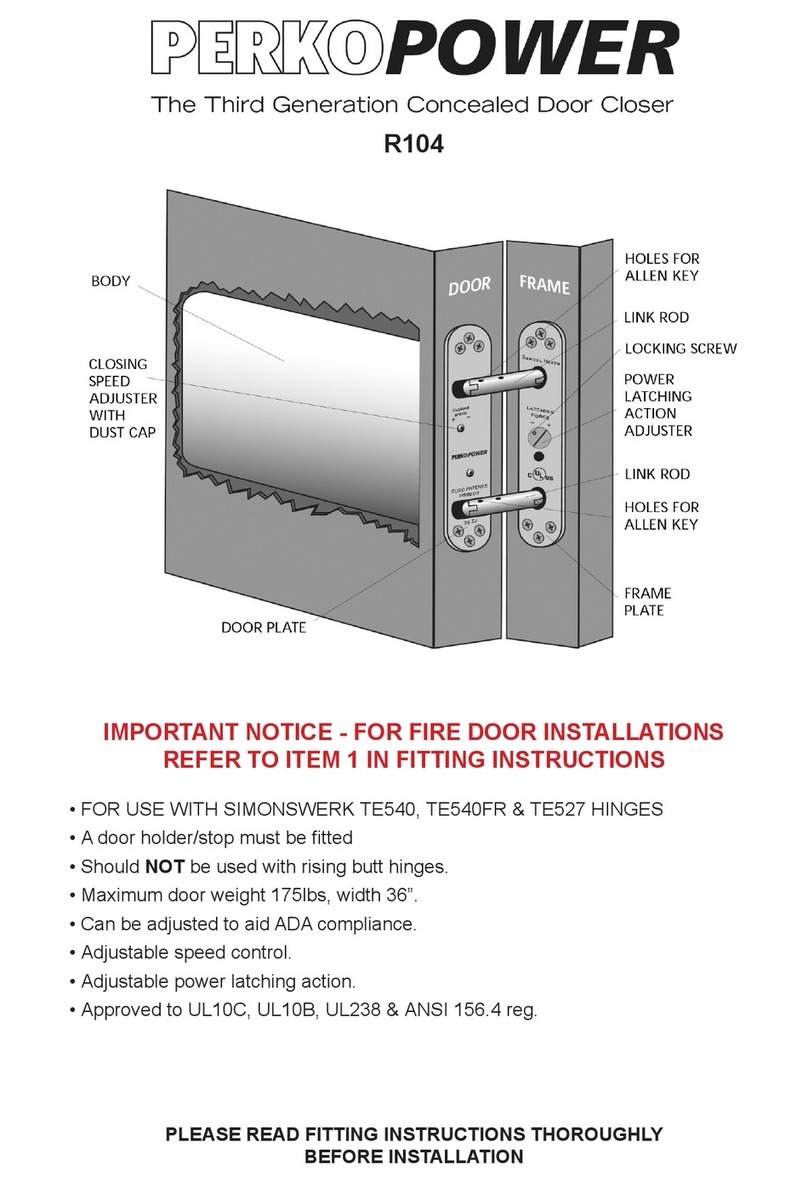

DESCR|,PTIONOF THEA,UTOMATISM

To reachtheinternal

parts

of theautomatism,remove

themetalliccapby levering

with a suitable

point-shaped

tool on the end sides.Pay particularattentionwhen removingthe cap so asto avoid damage

to the covering

parts.

Theautomatismiscomposedof:

l. Aluminiumfixingbase

2. Aluminiumendsides

3. Cap

4. Gearmotor

5. Electronicexchangemicroprocessor

1

6. Transformerwith fusible

wiringsystem.

T 630MA.

7. Encoder

group

for movementcontrol

8. Emergencybatteries

(optional)

24V-0.8Ah

9. Power

supplyterminalboard230Vac

i ,'-

.\ ,. I

ft l'" I"

I

ItF,l

]1 fl

t7-:

t?

1'\

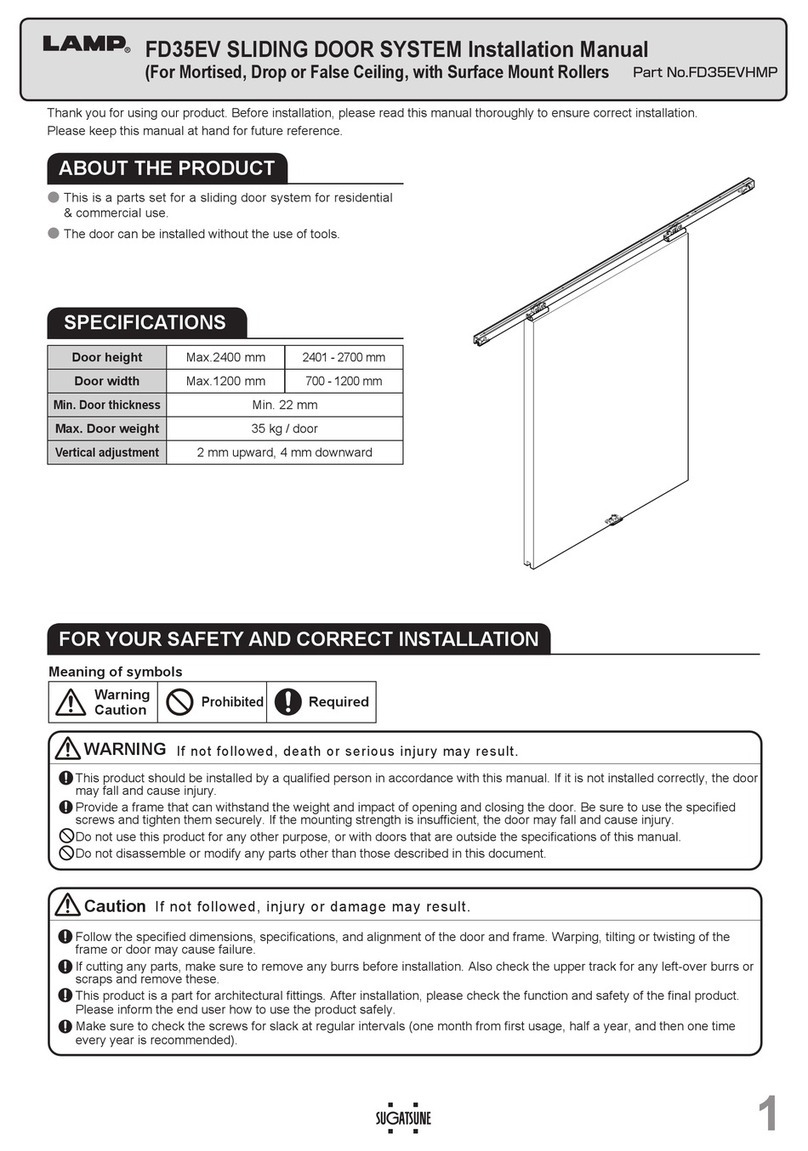

Powersunolv 230V

AC 50Hz

Rated power 60w

Rated motor torque 23Nm

Service Continuous

> 500cycles/day,withcapacityof300cycles/hourx 2hours

Operating temperature Boxinsidefrom0"Cto+50oC

Automatismdimensions

(mm) Heieht:79 Depth:

96.5 Lensth r","a"..ni

830 Leneth s"n";"":i 925

Automatism

weieht 7.6Ks. 8.6kg ,r.*""*'

Wins width (mm) 700

+ 1200

Wins maximumweisht 150Ke

Wing max. openinqangle 100'

I

iIsEli4ilo

The automaton is prearrangedby Sesamoto

operatewith different accessory

and peripheral

configurations. According to the configuration

chosen,

setthe cables

necessary

to guarantee

all

theconnections

totheperipheral

devices.

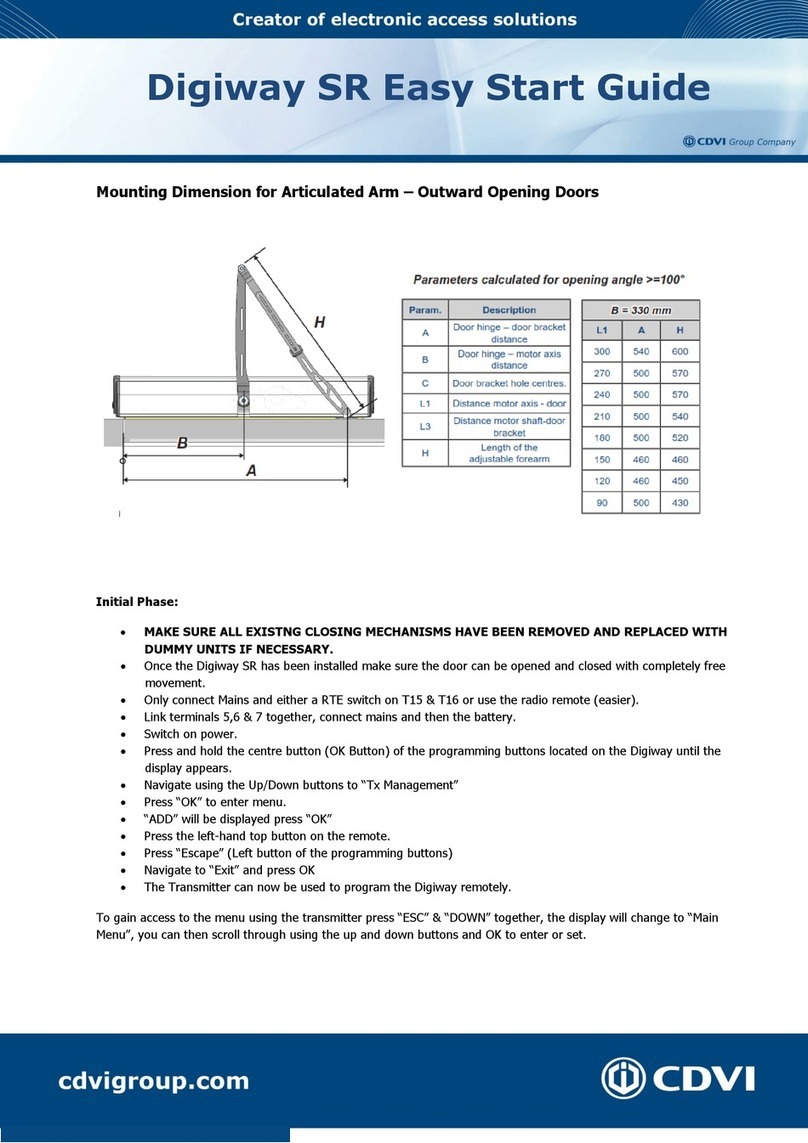

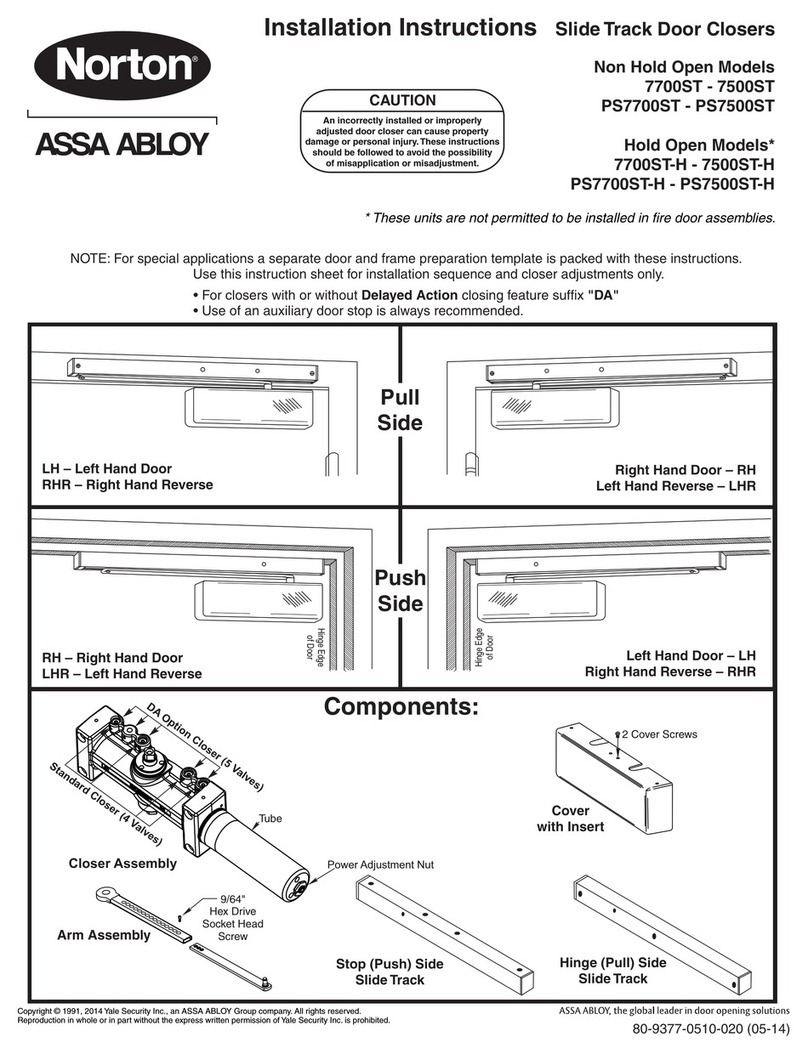

Fig.2

showsanexample

ofone

winginstallation

in

which the opening is commandedby a radar

sensor

to enter,and

by abutton

to come

out.

The figure schematises

the most importantparts

that form the finished installation (automatic

entry)andsome

of theperipheral

devices

thatcan

be

installed:

A. Boxin aluminium

extrusion

B. Opening-closing

operating

arm

C. Drawingarm

guide

D. Entryradar

E. Safetyactive

sensor

F. Night

time

closingdevice

G. Multilogic

selector

H. Openingbutton

atexit

l

I

tu

6

Therigiddrawing

armisusedwiththeautomatism

installed

on

theopening

sideofthe

door

(fig.3-4).

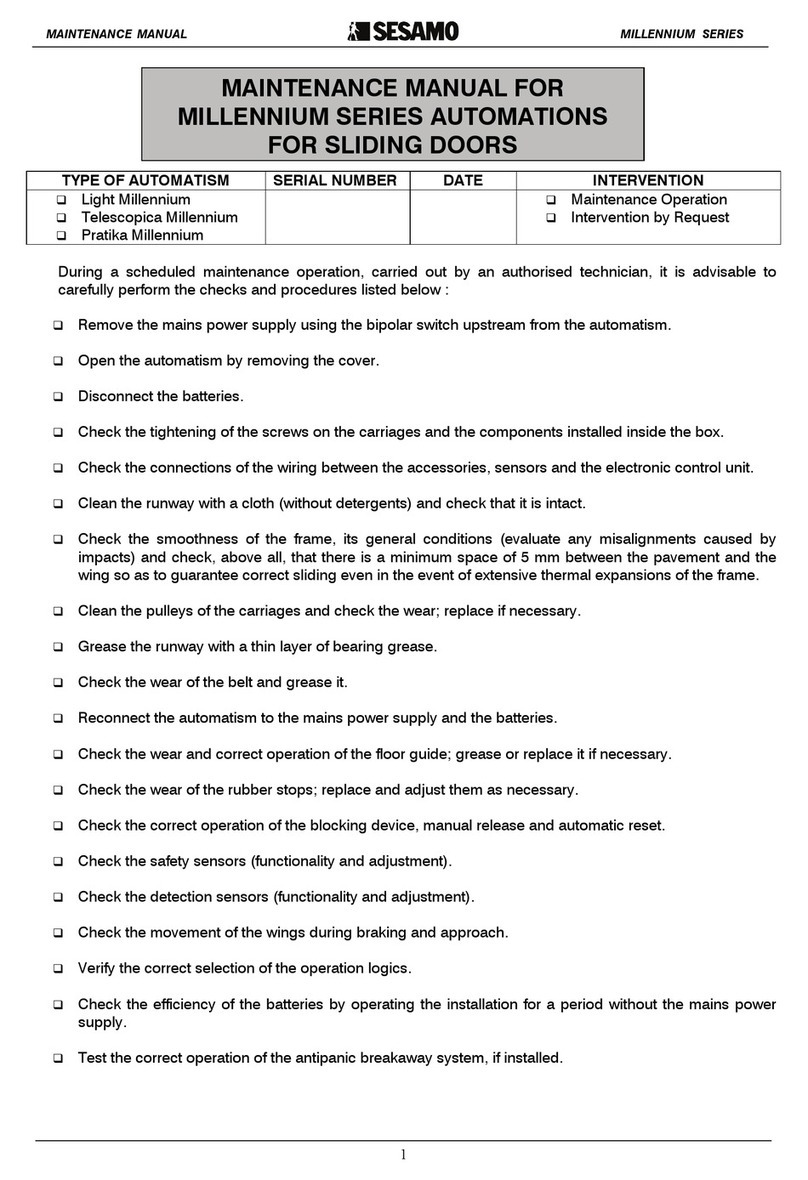

Forleftopening

wings

(wing

withanticlockwise

rotation

opening),

settheautomatism

asshowninFig.3.

co-)ci,

Hinge

axis Gearmotor

axis Drawino

rioid

arm

o .u'

t-

\t/o

/t\

/ : \ WARNING: useasa reference point the axis of the wing hinges and the gearmotor operating axis.

LJ,L.

'1r . 4 :.]:l

I5a L I ao6 -T-

.|r- '1

'1* ll ]J rr.' :

t r / il -l I

)'',+=a it

:.'tI

Hinge il /

-il/ r-/

r jOO _] / Guide's

rigid

arm , -,-,

ill

1

For right openingwings (wing with clockwiserotationopening),

setthe automatism

as shownin Fig.4 (the

reverseinstallation

compared

with theleft opening). 2

I

ttsEiAilto

t-

tf

I I o Drawing

rigid

arm

tl

rj

f- -r-=\\-

I ---=---- -.-

-N -_\\ -

t\\l

O-)

N

.1.

!-) Gearmotor

axis Hinge

axis

Guide'srigid

arm

Thediameters

of theholesfor fixine arenotedin Fis. 5.

830

A WARNING the definitivetighteningof the screwsshouldbe doneonly afterhaving checked

thatthe

verticalpositioning

of theautomatismensuresthatthehingeaxisandthegearmotor

axis(Fig.3-4)are

perfectly

parallel.

Therefore,afterhavinginstalled

therigid armand

therelativeguide,check

thatduringthe manoeuwe

the drawbolt of the arm doesnot force the rylindrical runner (Fig.6 part B). Any error of positioning or

tightening of the automatismwould in fact make the drawbolt of the rigid arm oscillate,in respect

to the

cylindricalrunner,more

thantheallowabledeviation,

andwouldconsequently

damage

parts

of theautomatism.

q

a.l

qg

o6

31 300

--*

_ub.5 ab2 *J

P -+r---

-+|- l

|,

'l aa. l

--rGjt= ^ ".:

-il -=-*q'*- -

-6

60/ (l

(O

V)6 (a1

=== I

aF, I

.-.-------*l o)

l--

(o

ra

126 1

+ I

, -2,1

LJI ++46 79+

*1 q

N

trs6AI||o

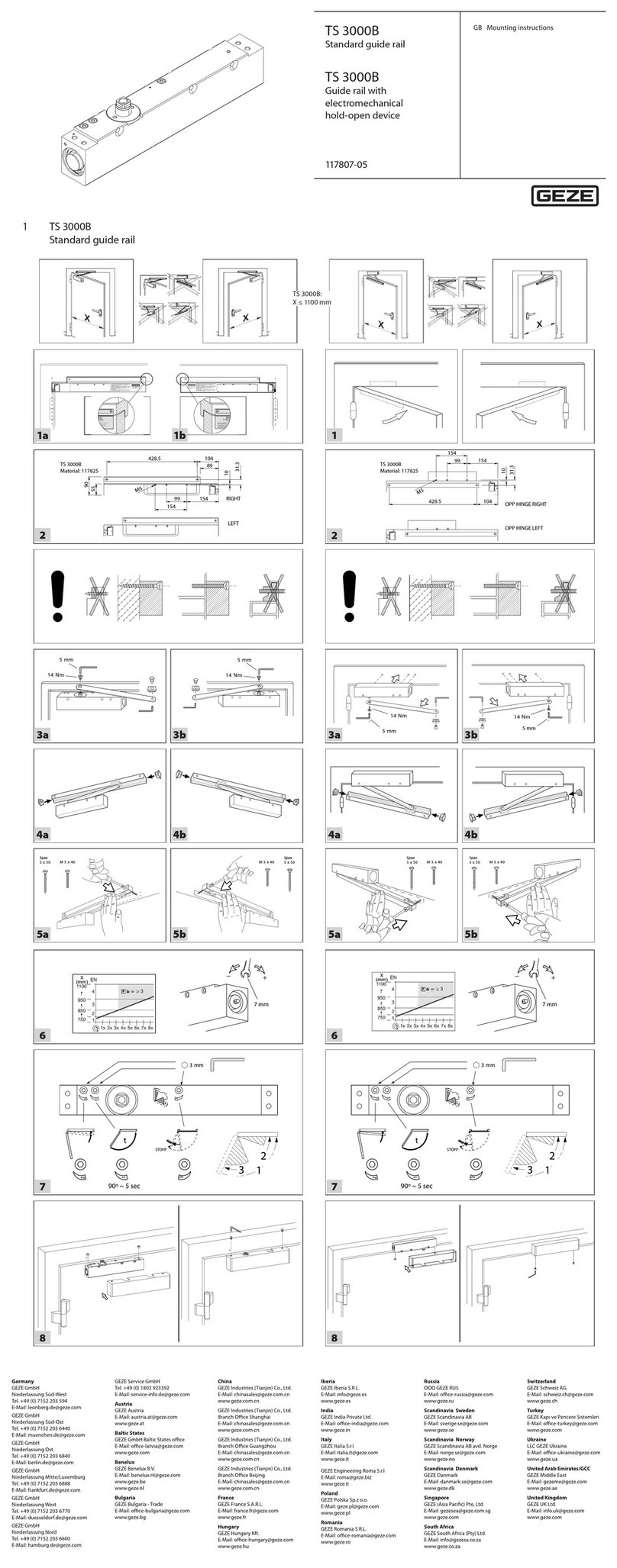

INSTALLATION

OF THEDRAWINGRrctD ARM AND

OF THEGU/IDE

(FtG,

3-4-6.8)

Reachtheguide

fixing box (Fig.6partD) takingoff the S924lA,cap.Makeatleast4 holes

corresponding

to the

"V" shape

in the guideprofile (Fig.6 part D). Use theseholesto fix the guideto the framewith appropriate

screws.Insertthe cylindrical runner(Fig.6 part B), with the relative shaft,inside the guide and distributea

uniformlayerofgrease

ontheslidingarea.

Subsequently,

oncethe installationof the rigid arm desoibed in fig.7 is finished,screwthe threadedshaft,

inserted

in thecylindrical runner,in the specialholeatthe extremityof therigid arm.Closetheguide

with the

capsand

screwssupplied.

I

tr!

v

a't

,'s 92,1/A.:i

qTH'

;r+1

ffi,,',,,,

)"

@i

*i

Insertthe threadedhexagon

in the upperpart

of thehexagonalhole

of thegearmotor(Fig.7

part

A).

Assemble

therigid armto theupperhexagon

with the flathead

screwsuppliedafter having

interposed

thewashers

asshownin thefigure.

Drowing rigid arm: beforetighteningthe

flathead screw, check carefully that the

distancebetween

the guideandthe rigid arm

is about 13 mm (fie.6). It is possible

to

achieve the right distance by varying the

number of washers placed between the

hexagons previously assembled (max. 8

washers)

(Fig.7 part B). Once the required

distanceis obtained,

tighten

theflathead

screw

well.

Articulated drawing arm: before tightly

shutting the flatheadscrew, carefully check

that

theupper

partof thearticulated

armeasily

rotates under the door frame and that the

obtainabledistance,

by adjusting

the washers

(max. n. 8) betweenthe hexagons,

ranges

between 12 and 24 millimeters measured

betweenthe coverof the automatism

andthe

upper

part

ofthe articulated

arm

(Fig.9).

/_- :

l I-.

Y

\/

. rir R

tr--

iISHiAMO

ADJUSTMENT

OFTHESIOPt TSIDE

THEGUIDE

(FtG.6-8)

Insert

the

lock(Fig.6

part

C) inside

the

spline

(Fig.6part

A); openthewingtothedesiredamplifude,

thenbring

thelockin contactwiththe

cylindricalrunner

(Fig.6-8part

B) andtightenthe

screwonthelock.

The

articulated

drawingarmisusedwhen

theautomatism

isinstalled

ontheopposite

sidetothatof theopening

ofthedoor.

For left opening

wings (wings with anti-clockwise

rotationopening)setthe automation

as shownin Fig. 9,

(using

thedetailsinfig.5).

Useas

amainreferencetheaxisof thewing hinges

andthemotorgear

axis,

(for wingswith right opening

(wings

with clockwise

rotation

opening)

all thedetails

arein reverse

compared

with thosein fig. 9).

Hinge

axis Gearmotor

axrs

ll-' n

'-

[,o,

Adjust andfix theheightofthe articulated

arm(procedure

described

in Fig.7) sothat it canrotate

easilyunder

thedoorframe,

sogettingadistance

between

theupper

partofthe articulated

armand

thelowerpartofthe cap

of theautomatism

of between12and24 millimetres(Fig.9).

Makeholesin theframe

of thediameters

shownin

fig.9 andfix to thelatter

thewing attachment

of thearticulated

arm

with theappropriate

screws.

Closethewing,

loosen

thefixing screws

situatedin theadjusting

slots

by lengthening

theextendible

partof thearm,follow thi

exact

geometry

shownin fig.10 partE. Fix the adjustment

by tightening

the setscrews

tightly in the extendible

partofthearmsousing

theholes

furthestapart.

/

i1

,LT

lj i-L

I

tffi

l r-

l;.

-{i

l-'

I

irsEsAlfto

WARNING When the door is

fully open,the opening

of thearmmust

not

exceed

140'

(fig.

l0).

Positioning

ofthewinglock:

Open the wing to the desired angle

(Max. 100') andfix therubber

doorstop

tothefloor

(not

supplied

fig.10

part

C).

Assemble

the optional stop on the articulated

arm using the screws

supplied.Checkthat when the door is

completely

open,the opening

of the arm doesnot exceed

140'. If the stopdoesnot comein contact,

tum the

shaped

plate

over

and

assemble

thestriker

asshown

in fig. I l.

Open

thewing to thedesired

amplitude

and

bringthestopin contact

with thearm(part

D fig.10)andtighten

the

fixing screws

tightly.

LO

:

x

STOP

L

ilsEsAMo

/!\ WanNfNC Before

performing

thefollowing operations,make

surethatthepowersupply(230Vac.)

isdisconnected.

Beforefeeding

theapparatus,carry

outthechecksseenin paragraph

"STARTING UP".

Introduce

thepower

supply

cablein thehorizontally

member,

paying

particular

attention

notto damagethecable

against

anymetaledges.

Connect

the mains

powersupplyandthe earthingcable

on theterminal board(Fig.l

part.9).

A WARNNG Neverreverse

thepowersupplywith theearthing

cable.Do notreplace

thefusiblewiring

system

with one

differentfrom that

provided

for bythebuilder:T 630MA (delayed).

It should

bepossible

to isolate

thepowersupplyfrom thegeneral

distributionboardthanks

to a bipolarswitch

withminimum

openingcontacts

equal

to3mm(not

included

onthesupply).

,/!\ WARNING: all theconnection

operations

onthe

terminalboards

ofthecardorof theperipheral

elementsmust

be

perfomedwith thepower

supply

off soasto avoidirreversible

damages

totheelectronic

apparatus.

/t\

/ : \ WARNING: anyrepair

orreplacement

mustbe

performed

by professionally

qualified

staff,

andin any

repairwork carried

outoriginalspare

parts

must

beused.

In thefigure,

theconnections

of theterminal

boards

situated

onthePIUMA electronic

exchanser

are

summarised:

0-13 Opening

safety

sensorN.O.

l-2-3-4 Multilogic

selector

entry

fig.l2 part

F)

5 Notused

6-13 Entry

radar

N.O.

7-13 Reset

buttonN.O.

8-14 Safetyclosing

contact

N.C.

9-13 Exitradar

N.O.

10-14 Safety

photoelectric

cellsN.C.

I I Interblock

entry

12 Interblock

exit

15-1

6 12Yactransformer

entry @ig.

I3 part

D)

17 Earthing

connection

18-19 Motorgear

power

supply

(Fig.13

part

A)

20-22 Electrolock

12124V

dc

power

supplyselectionable

from

themultilogic

selector(Fig.l

3part

B)

2l Batterynegativepole

(-)(Fig.13

part

C)

25 Battery

positive

pole

(+; (Fig.

13

part

C)

23-24 24Vac

transformer

entry

(Fig.l

3part

D)

26 Encoder

signal

(Fig.l3partE)

27 Encoder

signal(Fig.l3part

E)

28 Encoder

negative

pole

(Fig.13

part

E)

29 Encoder

positive

pole

(Fig.13

part

E)

Pig.lZPart G:terminal

boardfor sensors

power

supplywith 16-24V dc.

voltage

its6AM0

I

6:24V Dt;

Sofety

pno.|.o€,LP If-ia

celLs N.l:

Ro

do. r' N[]

DI

ND

SCK

To connect

two exchangers

A andB intheinterblocked

mode,

proceed

asfollows:

. connect

terminal11

of exchangerA with terminal12of exchanger

B

. connectterminal12

of exchanger

A with terminal1l of exchangerB

o connect

terminal2 of exchangerA with terminal

2 of exchanger

B.

Use

a 4x0.22

screened

cablefor theconnection.

Fortheconnection

of themultilogic selector,

usea 4x0.22

screened

cable.

Usethe 4 internalconductors

of the screened

cable,respecting

the numerical

correspondences

shownon the

printed labels

placedon both the terminalboardof the electronic

exchanger

andon the printed circuit of the

multilogic

selector

ontheside

ofthecomponents.

Connectthe screenof the cableused(connection

side in the electronicexchanger)

to the metal base

of the

automatism.

Insertthe

selectorinthe

specialboxso

thatthescreen

ofthe cable,

suitablyshortened,

cannot

comeintocontact

withthesurface

oftheprinted

circuitofthe selector.

itsEsAMo

''[ ,; Ir

tt

ft

L]

L-l

ll

fl

ti

f,l

II

tl

?+'\/

' l,r

SELF-ASSIGNMENT

SIGHTS:automatic

memorisation,

during

thereset

manoeuvre,

of theopening

and

closing

sights.

PUSH AND GO: oncethe installation

hasbeencompleted,

the apparatus

is readyto work both with

opening command

through extemal devices(radar,buttons, etc.) and with Push And Go opening

command

withoutthenecessity

of any

selectionfrom

the

multilogic

selector.Movingthe

opening

wing

to agiven

angle

(B)

@eginning

angleofthe

opening

manoeuvre

infig.l5) thewingopensautomatically.

Theextent

ofthe openingstarting

angle

(B)isadjustable

fromthemultilogic selector.

ANTI WIND OPERATION: adjustment

to the wind force in position of complete

closureso as to

opposetheforce

ofthewindthat

could

causeundesirable

door

openings,

(this

function

isexcluded

inthe

batteryoperating

system).

FRICTION SIGNALING: duringa reset

or a normal

manoeuvre,

theDSl4 led signals

the possible

presence

of excessive

friction.

ANTISQUASHING: automatic

limitation of the opening/closing

strength

and inversionof the wing

motioninpresence

of an

obstacle.

BATTERY: it ispossible

to select,

during

theinstallation

phase,

thetype

of battery

operation

(absence

of powersupply):anti-panic

or continuous

operating

mode.

INTERBLOCK: possibility of connecting2 automatisms(electronicexchangers

of the sameMCR

series)

to realise

aninterblocked

operation,

thatisto saythe automatic

opening

of oneautomatism

will

bereleased

onlyif the

other

one

iscompletely

closed.

MEMORISATION: the operating

parameters

selectedfrom the multilogic selector,

arepermanently

memorised

even

when

thereisno

power

supply.

SEMIAUTOMATIC OPERATION:

in thismode,

theautomatic

closing

of thedooris excluded

atthe

endof an

openingmanoeuvre.

Theclosing

must

beactivated

by theoperator.

MANUAL OPERATION:

in thismode

Radars,if installed,

areexcluded

andit is possible

to openthe

dooronly through

thepush

button

"oPENING BUTTON" onthemultiloeic selector.

iISESAIIIO

NOTE it isalways

possible,

in absenceofcurrent

andbattery,

tomove

thewingbypushing

it.

Sf{F,ftnG UP ':; "rn,, #t 'ft}1. .,

Before

startingup,checkthat:

- the(optional)

battery

isnotconnected - thereisnoobstacle

inthe

wing opening

zone

/t\

/ : \ WARI\ING To guarantee

correctoperation

andto avoid damages

to the electronic

exchanger,

before

connecting

theemergency

battery,

make

sure

that theelectricity

supply

to theapparatus

isswitched

on.

/!\ WInNING Select

rherype

of arminsralled

through

theW2bond

(Fig.t6):

Open

bond: Optimisation

of themovement

for thedrawing

rigid arm.

Short-circaited

bondl Optimisation

of themovement

for the

pushing

articulated

arm.

/r\

/ ! \ WARNING If no optionalsafety

closing

deviceis installed,

check

thatthe special

terminals8-14 are

N.C.configurated,

thatisto sayshort-circuited.

If not,it isnotpossible

to start

theapparatus.

/r\

/ ' \ WARNING If no safetyphotoelectric

cells areinstalled,

checkthat the special

terminals10-14are

N.C. configurated,

thatisto say

short-circuited.

If not,it isnotpossible

to start

theapparatus.

Power

supply

totheapparafus.

Theautomatismperforms

amanoeuvre

of auto-assignment

of thesightsat areduced

speed

accompanied

by the

issue

of anintermittent

acoustic

signal;

theauto-assignment

manoeuvre

shouldhave

thefollowing piur"s,

r the

doorclosesfor awhile (to

facilitate

therelease

ofthepossible

electrolock)

. thedooropens

until it opens

fully against

thestop

o the

doorcloses(including

therelease

ofthepossible

electrolock)

and

stopsonce

closed

,/l\

/ ! \ WARNING If theauto-assignment

manoeuvre

doesnotproceed

according

tothesequence

first described,

switchthepower

supply

off and

reverse

thepower

supply

cables

ofthemotor.

Multilogic selector

not installed: once

thesights

auto-assignment

manoeuwe

isflrnished,

theapparatusisready

to operate

either

in Push

and

Gologic or in two radars

logic.

Multilogic Selector

installed: once

thesights

auto-assignment

manoeuwe

isfinished,

theapparatus

isready

to

operate

andis

positioned

in"CLOSED

STOp"logic.

Logics description:

A ENTRYAND EXIT RADAR

B ONLY EXIT RADAR

C OPENSTOP

D CLOSED

STOP

E MANUAL

F OPENING

BUTTON

G RESET

H "DISCHARGED

BATTERY ''LED SIGNAL

""@@

TE@

Tgg

;ru@

SfsAl!!0

B

D

F

H

10

itsEsAilo

OPENINGBUTTON: operatesthe openingeverytime oneof the following logicshas

beenselected:only exit

radar,

entryandexitradar,

manual.

Theadjustments

throughthemultilogic selectorshould

beperformed

with thewingsmotionless

andclosed.

D ADJUSTMENT OF THE OPENING SPEED: selectkey D (closedstop) and prohibit the passage

of

people.

Simultaneously

press

key A (entry andexit radar)andkey B (only exit radar).Threeconsecutive

acousticsignalsandthe lighting of the two leds corresponding

to the pressed

keys signalthe effective

resetting

of thepreceding

adjustment.Then,everytime key G (reset)

is pressed

onthemultilogic selector,

the openingspeedshallbe reduced

until it reaches

the minimum valueprogrammed

correspondingto l l

consecutive

pressures.

Oncethe adjustmentis finished,

press

key A (entryandexit radar)

andkey B (only

exitradar)

againsimultaneously

tomemorise

theselecteddata

and,to leavetheadjustment

mode.

tr ADJUSTMENT OF THE CLOSING SPEED: selectkey D (closedstop) and prohibit the passage

of

people.

Simultaneously

press

key C (open

stop)

andkey D (closed

stop).Threeconsecutive

acousticsignals

and the lighting of the two leds corresponding

to the pressed

keys signal the effective resettingof the

preceding

adjustment.

Then,

everytimekeyG (reset)

ispressed

onthemultilogic selector,theclosing

speed

shallbereduced

until it reaches

theminimumvalue

programmed

corresponding

to 5 consecutive

pressures.

Once

the adjustmentis finished,press

key C (openstop)andkey D (closed

stop)againsimultaneously

to

memorise

theselected

dataandleave

theadiustment

mode.

tr ADJUSTMENT OF THE WAITING TIME WHEN OPENING: select

key D (closed

stop)and

prohibit

thepassage

ofpeople. Simultaneously

press

key E (manual)

andkey F (opening

button).Threeconsecutive

acousticsignalsand the lighting of the two leds corresponding

to the pressed

keys signalthe effective

resetting

of thepreceding

adjustment

(min. blockingtime I sec.).

Then,

everytime key G (reset)

is pressed

on the multilogic selector,

the waiting time at openingshall be increased

by about 2 secondsuntil a

maximumincrease

of about50 seconds

corresponding

to 24 consecutive

pressures.

Oncethe adjustmentis

finished,

press

key E (manual)

andkey F (opening

button)againsimultaneously

to memorise

the selected

dataandto leave

theadjustment

mode.

O ADJUSTMENT OF THE PUSHING FORCE IN POSITION OF COMPLETE CLOSURE,:

selectkey

D (closed

stop)and

prohibitthepassage

ofpeople. Simultaneouslypress

key C (open

stop)andkey B (only

exit radar);an acoustic

signal and the lighting of the leds coresponding to the pressed

keys signal the

effectiveresetting

ofthe preceding

adjustment

(nopushing

force).

Then,every

time key G (reset)

ispressed

onthemultilogic selector

thepushing

forceshallincrease

until it reaches

amaximum

valuecorresponding

to

15consecutive

pressures.

Oncethe maximumvaluehasbeenreached,

a furtherpressure

of key G (reset)

bringsthepushing

force

valueto theminimumandthecard

signalsit by emittingan

acousticsignal.

To complete

theadjustment

and

to memorise

theselected

value,simultaneously

press

key C (open

stop)

and

keyB (only

exitradar).

The

selectoris

positioned

ontheD logic

(closed

stop).

I ADJUSTMENT OF THE SAFETY SENSOREXCLUSION RATES: press

key D (closed

stop)and

prohibitthepassage

ofpeople. Simultaneouslypress

keys

C (open

stop)

andF (opening

button);

anacoustic

signalandthe lighting of the ledscorresponding

to the pressed

keys signalthe effectiveresetting

of the

preceding

adjustment(ct: 0ofig.15). Then,every

time key G (reset)

is pressed

on themultilogic selector,

theanglectincreases

until it reaches

amaximum

valuecorresponding

to l6 consecutive

pressures.

Once

the

maximum

valuehasbeenreached,

afurther

pressure

of keyG (reset)

brings

theangle

value

to theminimum

andthe card signals

it by emitting an acoustic

signal.To complete

the adjustment

andto memorise

the

ll

iISESAMO

selectedvalue,

simultaneously

press

keysC (open

stop)andF (opening

button).Theselector

ispositioned

ontheD logic

(closed

stop).

Safety

sensor

"i \

\ nil ;'.' \

.,)-"lt,nl \

-Li

i \

\-, cl,--

<-

/

cr

B: Exclusionanglefor safetysensorwith doorin openingstate

: Angle

openingPushand

Go

SEMI-AUTOMATIC

OPERATION

To usethe automatismin semi-automaticlogic, it is necessary

to carry out the following operationon the

multilogic

selector.

Simultaneously

press

thekeys

C (Stop

open)

andE (manual);

a acoustic

signalisemitted

and

theleds

arecontemporarily

turnedon related

to thekeysA (input

andoutputradar)andF (opening

push

button).This

situation

(scheduled

bythe

company)

pointsoutthatthedevice

will work in automatic

mode.By pressing

thekey G

(reset)

once,theleds

areturnedonrelated

tothekeys

oflogic B (radaroutputonly)

andE (manual);

inthiscondition

thedevicewill work in semi-automatic

mode.

Oncethatthesituationischosenin which is desired

to work, save

the

formulation

bysimultaneously

pressing

thekeys

C (open

Stop)andE (manual).

In semi-automaticlogic,

theinput

oftheRadarscommand

bothopenings

andclosings.

Commandsof openingor

closingcan

eventuallybe

given

bypressing

thekey

F (openingpush

button)onthemultilogic

selector.

I

WARNING: thefollowing adjustments

shouldbeused

only andexclusively

by PROFESSIONALLY

LIFIED STAFF.

Through

the multilogicselector,it is possible

to perform

a series

of adjustments

to optimisethe apparatus

operation.Thelist

of such

adjustments

canbe

found

inthefollowing

table.

,ADJUSTMENTS ,,

STARTING BRAK-EIN OPENING MODE A (entryandexit radar)

+ C (openstop)

BRAKING INTENSITY D (closed

stop)

+ E (manual)

lSIAPPROACH

SPEED A (entry and

exit radar)

* E (manual)

2'd APPROACH SPEED B (only exit radar)

+ F (opening

button)

PUSH

AND GOANGLE D (closed

stop) + A (entryandexit radar)

A

QUA

12

[ISEliAilO

ELECTROLOCK

EXCLUSION

PROCEDURES ,1 D (closed

stop) + B (only exitradar)

ELECTROLOCK VOLTAGE l2/24V Dc A (entryandexit radar) + F (openingbutton)

RECOVER

INITIALVALUES B (only exit radar)

+ E (manual)

Toperform

theadjustments

quoted

inthistable,

usethefollowing procedure:

r selectD (closed

stop)and

prohibit

the

passage

ofpeople;

r simultaneously

press

thepair of keysrelated

to theparameter

to beadjustedonthemultilogic selector.The

ledsrelating

tothepressed

keys

arelit up.

. press

key A (entryandexit radar)

andthenkey B (only exit radar).The two keysmust bepressed

the one

following the other but not simultaneously.If thesequenceof keysis wrong,theapparatus

automatically

exittheadjustment

procedure

andit isnecessary

to startagainfrompointI.

r if the procedures

of the preceding

point havebeencorrectlyperformed,

the apparatusemitsan acoustic

signal

(different

from thatfor thestandard

adjustments).

By pressing

keyG (reset)

it ispossible

to adjust

the

parameter.

o To complete

theadjustment

andto memorise

theselectedvalues,

press

againthepair of keysrelated

to the

parameter

thatis beingadjusted

onthemultilogic selector.Keeppressed

until theCLOSED STOPled is lit

up.

of fi*E

WARNING: the following adjustments shall be performed only and exclusively by

FESSIONALLY QUALIFIED STAFF

STARTING BRAKE IN OPENING MODE: this regulation

makes

it possible

to anticipate

or delaythe

startingof the braking in openingmode.As soonas it is enteredin regulationmode,the value of the

parameter

is setequal

astheone

programmed

by thecompany.

By pressing

thekey G (reset)

each

time,the

starting

of thebrakeisanticipated

upon

to theattainment

of thehighest

admitted

value.

Whenthemaximum

valuehas

beenreached,

afurtherpressure

of thekey G (reset)

setstheparameter

atthemost

attheminimum

value,corresponding

tothemaximum

delay

possible

for thestarting

of thebraking;thissituationissignalled

by an acoustic

signal from the device.From now on, further pressures

on the key G (reset)involve an

increase

of the instantof starting

of the brakingup to the attainment

of the initial value (valuesetby the

company).This

sifuation

issignalled

bysonorous

emission.

BRAKING INTENSITY: regulates

thebrakingintensity

thatprecedes

theslow approach

of thewing to a

stop. The value programmedby the company for this parameteroptimisesthe movement in most

installations

with various weights and frame dimensions.

Nevertheless,

in caseof specialfittings and

demands

it ispossible

to intervene

to increase

theintensity

with whichtheframeisbraked.

As soon

astheadjustment

mode

is activated,

thebrakingintensity

is stated

atthevalueprogrammed

by the

company

(minimumintensity).

Forevery

pressure

of keyG (reset)

theintensity

decreases

until it reaches

the

maximum value corresponding

to 19 consecutive

pressures.

Oncethis limit has beenreached,

a further

pressure

of key G (reset)

bringstheparameter

to the minimum value andthe situationis signalled

by an

acoustic

signal

ofthe apparatus.

A

PRO

o

B

t3

TISBAMO

O I't APPROACH SPEED:thephase

of approach

isdividedintotwo zones

of differentspeeds.Through

this

adjustmentit ispossible

to varytherateof speedrelatedto thefirst partof theapproach

thatfollows braking

phase

described

before.As soon

astheadjustment

modeis entered,

thespeedissetatthevalue

programmed

by the company.Then, for every pressure

of key G (reset)the speedis increased

until it reaches

the

maximumvaluecorrespondingto 14consecutive

pressures.

Oncethemaximumvaluehasbeenreached,

a

funherpressure

of key G (reset)

brings

this parameter

to theminimumvalueandthis situationis signalled

by anacoustic

signalofthe apparatus.

Fromnow on,furtherpressures

ofkey G (reset)

increase

thespeed

until it reachesthe initial value (value programmed

by the company)corresponding

to 13 consecutive

pressures

andanacoustic

signalis emitted.

i 2"dAPPROACH SPEED: it allowsthe change

of speedrelatingto the secondzoneof approach

(stopper

approach

speed).As soonastheadjustment

modeisentered,thespeedissetattheva.lue

programmed

by the

company.Then,for everypressure

of key G (reset)

the speedis increased

until it reaches

the maximum

value corresponding

to 15 consecutive

pressures.

Oncethe maximum value has beenreached,

a further

pressure

of key G (reset)

bringsthis parameter

to theminimum valueandthis situationis signalledby an

acousticsignalofthe apparatus.

Fromnow on,furtherpressures

ofkey G (reset)

increase

thespeeduntil it

reaches

theinitial value

(value

programmed

by thecompany)

corresponding

to l3 consecutive

pressures

and

anacoustic

signalis emitted.

O PUSH AND GO ANGLE: make reference

to fig. 15. The angle B can be adjusted

so as to vary the

beginningpoint of PUSH AND GO opening.

The value programmed

by the companyis the minimum.

Entering

theadjustmentmode,

theparameter

issetattheminimumvalue;for every

pressure

of keyG (reset)

theangleincreases

until it reaches

themaximum

valuecorresponding

to l4 consecutive

pressures.

Oncethe

maximumvaluehas

beenreached,

a furtherpressure

of key G (reset)

bringstheparameter

to theminimum

value

and

thecardsignals

thissituation

with anacoustic

signal.

D ELECTROLOCK EXCLUSION PROCEDURES: in casethe apparatushasbeeninstalled

on a devices

without electrolock,it is usefulto performthe following adjustments

so asto exclude

the unlocking and

resetting

procedures.

When enteringin the adjustment

mode,the ledsrelated

to keysE (manual)andA

(entryandexit radar)

arecontemporarily

lit up.This situation

(programmed

by thecompany)

showsthatthe

apparatus

will work with theelectrolock

procedures.

By pressing

key G (reset)

once,theleds

related

to the

keysof logic B (only exit radar)

andF (opening

button)arelit up;in this condition

theapparatus

will work

without the electrolock procedures.

Once the desiredmode has been chosen,memorisethe data bv

simultaneously

pressing

thepairof keys

related

tothisadjustment

ontheselector.

D ELECTROLOCK VOLTAGE l2/24V DC: with thisadjusfinentit ispossible

to choose

thepowersupply

levelof the electrolock.

Whenenteringin theadjustment

mode,

the ledsrelated

to keysE (manual)

andF

(openingbutton) are lit up. This situation(programmed

by the company)

showsthat the apparatus

shall

supplya 12V DC voltagefor the electrolock.

By pressing

key G (reset)

once,

the ledsrelated

to keysB

(only exit radar)

andA (entryandexit radar)

arelit up; in this condition

theapparatus

shallsupplya 24 y

DC voltage for the electrolock.Once the appropriate

voltage has been chosen,

memorisethe data by

simultaneously

pressing

thepairof keys

of theselectorrelated

totheadjustment.

t4

itsEsAI[0

Isa

:ti

r//."7,\

/ll-l

j \.'r'i/,

r-t

f+

" SEAm@

signals,if lit, thepresence

of the24V acfeeding

voltage

supplied

bythetransformer

Diagnostic

led

not

used.

If lit, it signals

theclosed

position

of thephotoelectric

cell

operating

andthephotoelectric

cellisnotintenupted.

Whenlit it signalstheclosing

of the"reset"

contact

Whenlit it signals

theclosing

of the"radar

in" contact

When

lit it signals

theclosing

of the"radar

out" contact

contact,

which means

thatthe amplifier is

It signals,in presence

of interblock

connection

between

two cards,themomentary

blockage

of thewings

because

of thepresence

of movement

ontheotherinstallation.

It lightsupto signal

thecontact

closing

ofthe safety

closingdevice.

It signals

thepresence

of 12

V acfeeding

supplied

by thetransformer.

It lightsupto signal

adamage

of theapparatus.

It lights

uptosignal

thatthemuttilogic

selectoris

connected

totheelectronic

exchanser.

Flashing

duringthe

acquisition

ofa stop

sight.

Bondto beshort-circuited

in presence

of emergency

batteryinstalled.

Open bond: optimisation

ofthemovement

for therigid drawing

arm.

a

a

0

a

o

a

o

7

e,

:,

4

.)

2

1

0

n\4

llIrl

ul!

Fl Fusible

central

power

supplyl.F2A

F2 Fusible

motor

power

supply:

T 6.3A (delayed)

F3 Fusible

battery

branch

tomotor:T 6.3A (delayed)

DSI Lit when

theapparatus

isoperating

with netvoltage,

and

off whenoperatingwith theoptionalbattery

DS2 Flashing

if theencoder

detects

amovement

of the

wings.

D53

D54

DS5

D56

DS7

DS8

D59

DSlO

DSII

DSI2

DS13

DSI4

w1

w2 Short-circuited

bond: optimisation

of themovement

for thepushing

articulated

arm.

W5 Openbond'.in case

of lackof netfeeding,

theapparatus

continues

itsnormal

running

fedby thebattery.

Short-circuited

bond: in case

of lack of net feeding,

the apparatus

bringsthe wing in position..Open

Stop", and maintains

this state

up to the retum of the net feedingor to the selection

of a new logic

through

themultilogic

selector.

l5

pl

l ,

I

ilsEsAilo

:...: it;::.

Delivertheguarantee

andinspection

certificatesfilled in according

totheinstructions

indicated

onthecertificate

itself. The certificates

shouldbe sentto Sesamo

within eight daysfrom the date of inspection.

Deliver the

technicaldocumentation

of theproduct

tothecustomer.

Turnoff thepowersupplyusing

thebipolar

switchontheautomatism.

Disassemble

thearmandopen

thecapof theautomatism.

Checkthe

tighteningofthe screwsandthe

electricconnections.

Check

thatthelogics

areworking

properly,

also

thesensorsand

batteries

ifinstalled.

Closethecapandreassemble

thearm(Grease

theguide

if installed).

Theassemblerwho motorises

a doorbecomes,

according

to thedirective98137lEC,

themanufacturer

of the

automaticdoormachine

andmust:

r Prepare

theTechnical

Brochure

with thedocuments

quoted

in Appendix

V of theMachines

Directive

andkeepit foratleast

10

years.

e Fill in the EC declaration

of conformity

according

to AppendixII-A of the machines

directive

and

deliveracopy

of ittotheuser.

. Affix the EC mark on the motorised

door according

to point 1.7.3

of AppendixI of the machines

directive.

(Directive

98137CE,Appendix

II, part

B)

Manufacfurer:

SESAMO

S.R.L.

Address: Strada

GABANNONE

8/10

- 15030

TERRUGGIA

- AL

Declares

that

thePIUMA product

o isbuilttobeincorporated

in amachine

ortobeassembled

with othermachines

tobuildamachine

provided

by the98137

ECDirective,

whenmodified;

r doesnot

therefore

conformin allpoints

tothe

provisions

ofthisDirective

inthatit isnotyetassembled

with

theothercomponents.

o conforms

tothe

conditions

ofthefollowing

otherECDirectives:

o 89l336lEEC

Electromagnetic

Compatibility

andlater

changes

c 73l23lEEC

Low Tension

andlater

changes

And that

thefollowing (parts/clauses

of) thecoinciding

regulations

havebeen

applied:

D

o

D

tr

D

r andfurthermore

declaresthatit is not allowedto use

themachinery

until themachine

in which it shallbe incorporated

or of which it shall becomea componenthasbeenidentified and declaredin conformity with the conditionsof the

98/37ECDirectiveandwith thenationallegislation

which replaces

it.

. EN60335

- I

o EN 60204-1

SESAMOS.R.L.

Str.

Oabmnone 8/10

15030

Temrggia AL - Italy

tel. +390t4240322314

fax. +39 0142 403256

www.sesamo.org

EN50081-l

EN50082

-2

SESAMO

S.R.L.

THE

SOLEADMINISTRATOR

ALDO

AMERIO

16

Table of contents

Other Sesamo Door Opening System manuals

Sesamo

Sesamo MILLENNIUM SERIES Operating instructions

Sesamo

Sesamo Puma Millenium User manual

Sesamo

Sesamo Roto K3 User manual

Sesamo

Sesamo PROSWING R Simple manual

Sesamo

Sesamo Digidor User manual

Sesamo

Sesamo Digidor User manual

Sesamo

Sesamo PROSWING User manual

Sesamo

Sesamo SwinGo User manual

Sesamo

Sesamo LIGHT MILLENIUM User manual

Sesamo

Sesamo smart PRO User manual