Copyright © 1991, 2014 Yale Security Inc., an ASSA ABLOY Group company. All rights reserved. Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited. 80-9377-0510-020 (05-14)

ASSA ABLOY

4Opening Cycle

B

a

c

k

c

h

e

c

k

g

n

i

n

e

p

O

1/8"HexKey

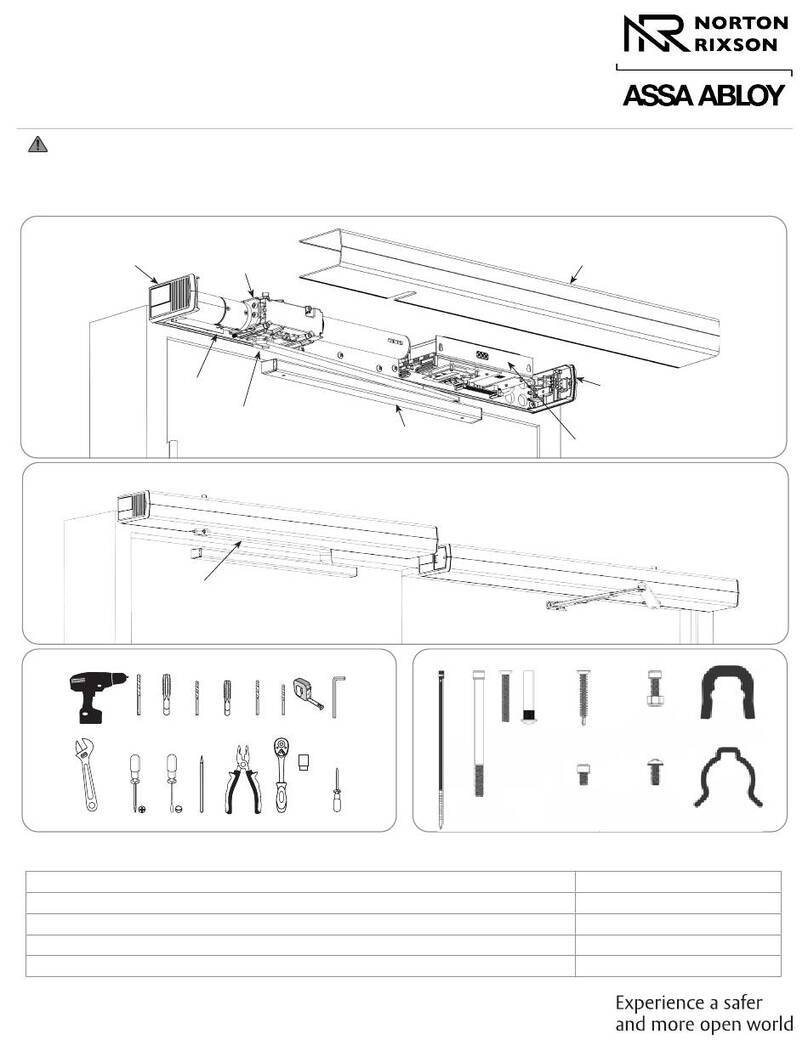

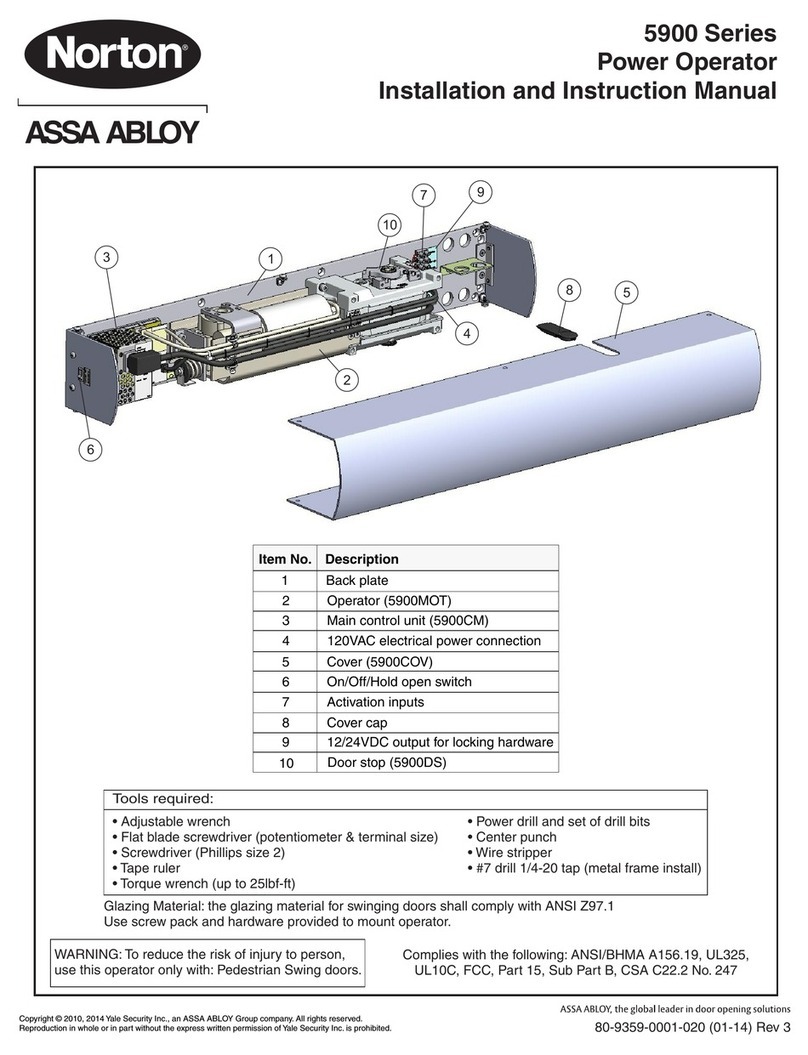

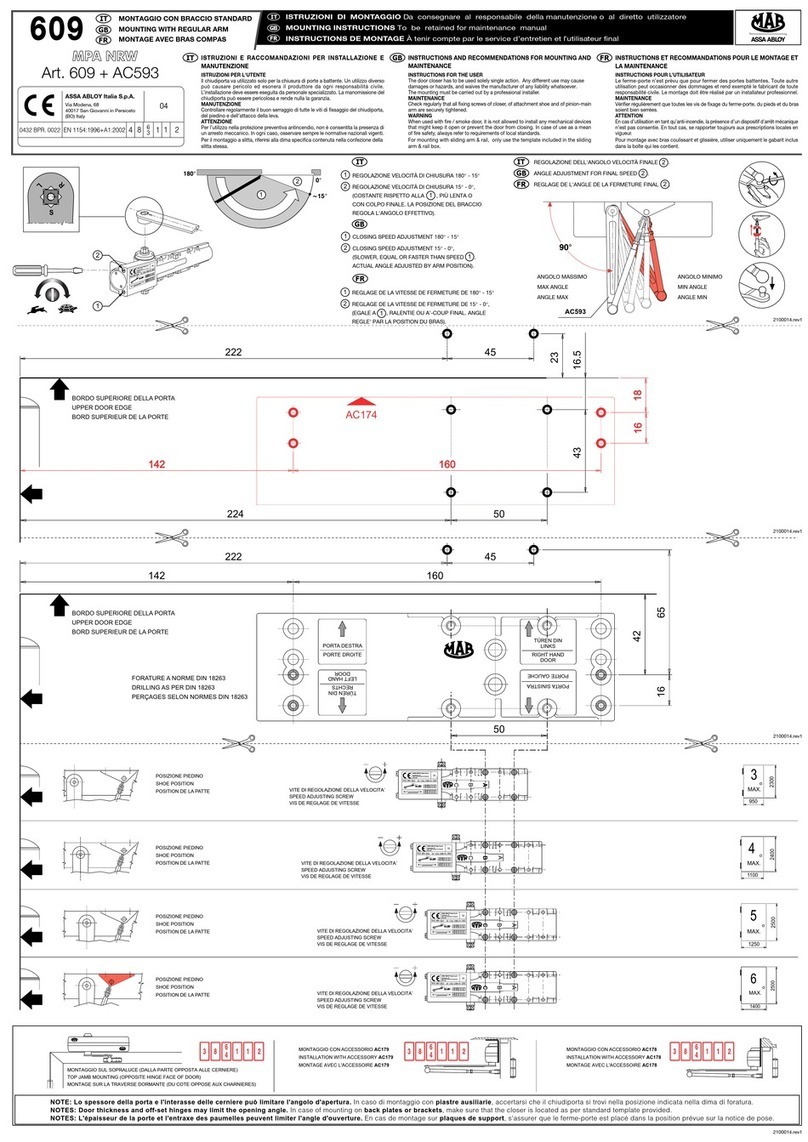

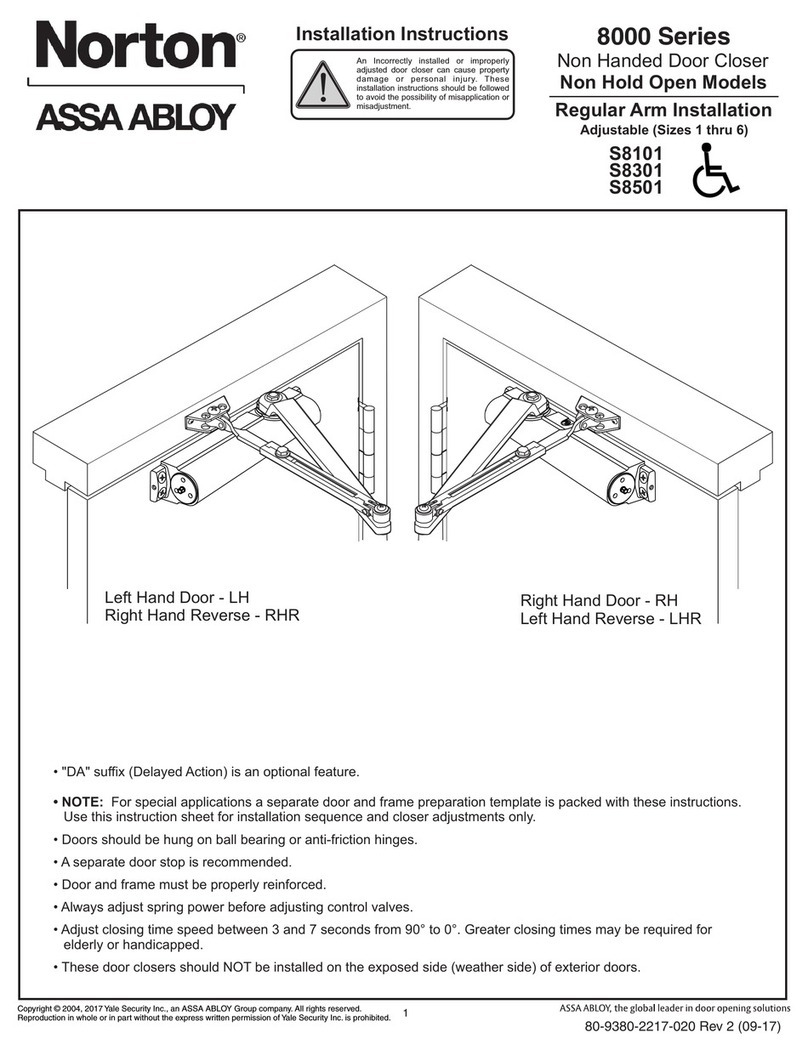

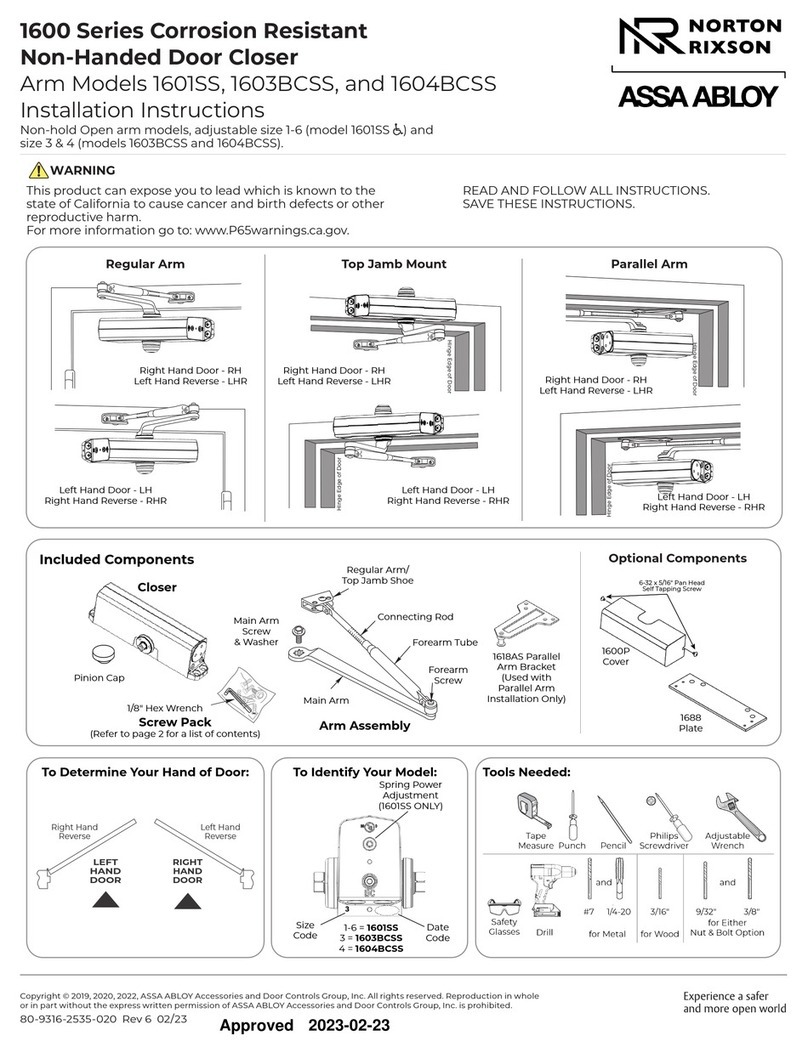

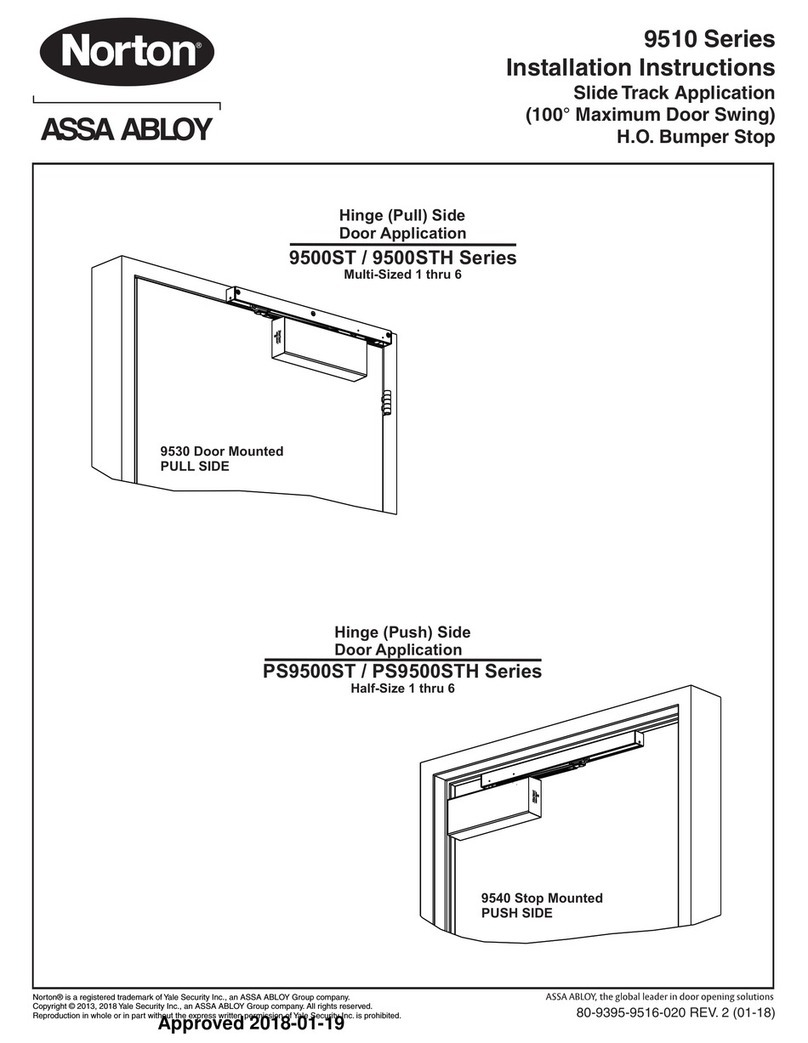

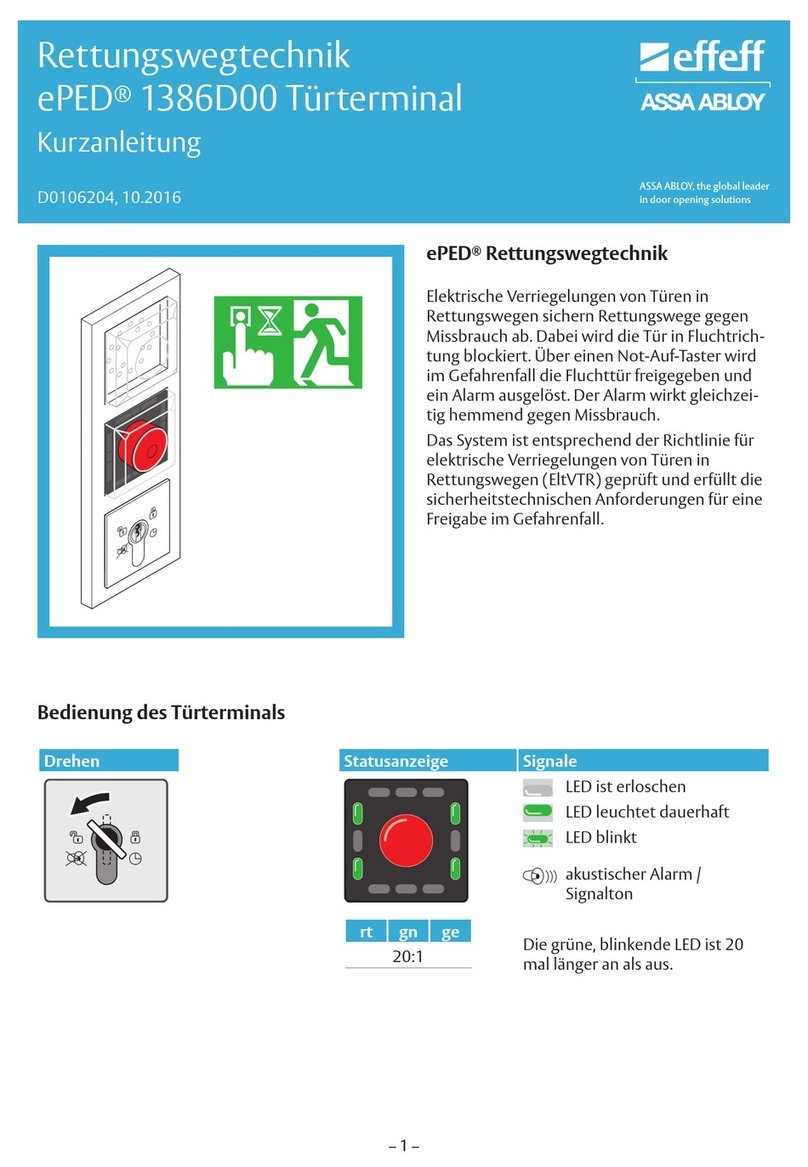

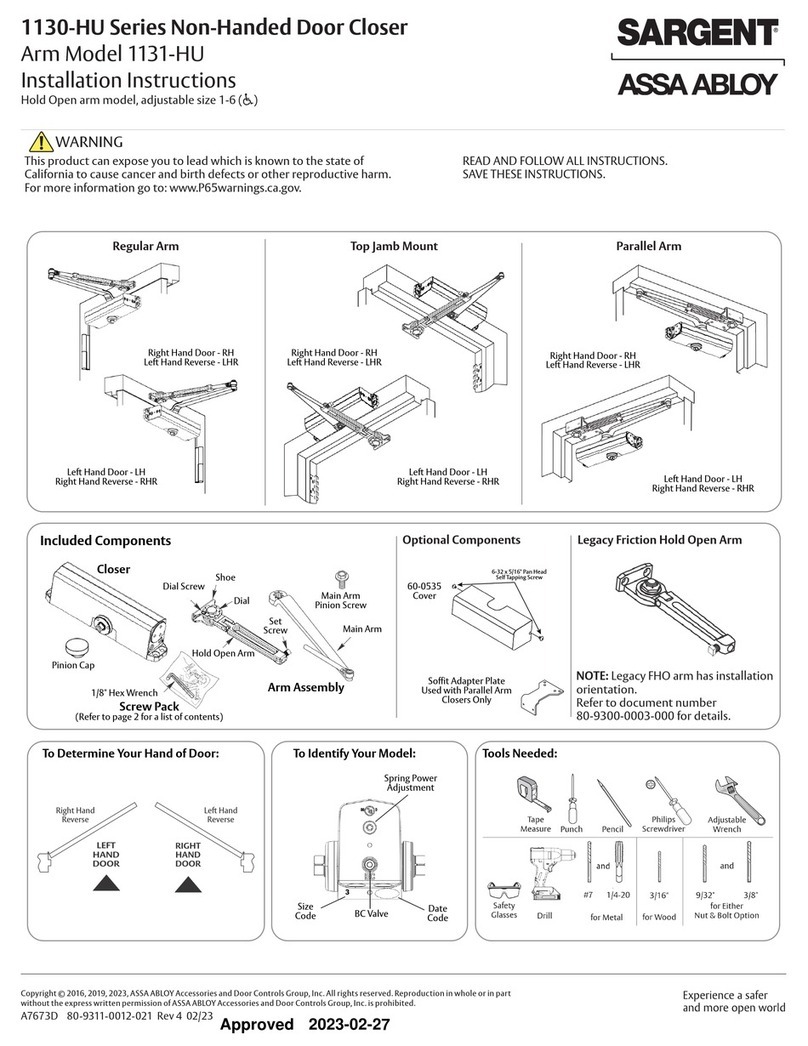

IncreaseDecrease"P" (Normally Closed)Open for backchecklater in door-openingcycle."B"(NEVER CloseCompletely)Opening CycleFigure 4Closing Power ControlFigure 1Adjustment InstructionsArm Attachment to TrackInsert arm stud into slide block in track. Secure by pushing in on the retainer clip that extends from the slide block, until it is flush with the slide block. Door Opening Angle and/or Hold Open Angle:Remove 9/64" hex drive socket head screw from arm. Open door to desired angle and install hex-drive socket head screw into hole in adjusting rod that is aligned with the hole in the adjusting tube.Closing Power7700ST Models come in three different sizes (4 thru 6), each power size can be increase by 50%.7500ST Models are fully adjustable for proper sizing. See chart on page 2 or 3.To adjust closer power - See Figure 1.Closing Cycle (hydraulic control) Standard Closer Only See Figure 2a.Valve "L" controls door speed in Latch range.Valve "S/D" controls door speed in Sweep range.Adjust as shown in Figure 3.Delayed Action Closer OnlySee Figure 2b.Valve "L" controls door speed in Latch range.Valve "S" controls door speed in Sweep range.Valve "S/D" controls door speed in Delay range.Adjust as shown in Figure 3.Opening Cycle (hydraulic control) See Figure 4.Valve "B" cushions (slows) door opening in the backcheck range.Valve "P" allows "backcheck" to begin later in the opening cycle.Adjust as shown in Figure 4.On/Off Hold Open Feature:Slotted screw, accessible thru hole in face of track, engages or disengages the hold open feature with 1/4 turn of the screw. Hold open units are not permitted in fire door assemblies.Hold Open Power Adjustment:If more hold open power is required, the power may be increased by turning the adjustment screw in the end of the track nearest the hinges. Use 9/64" hex wrench provided and rotate adjustment screw clockwise to increase holding power.Installation of Cover:Fasten cover to closer with two screws provided:• Cover fastens at the top of closerClosing CycleFigure 22B2AStandardClosing CycleDelayed ActionClosing CycleClosedClosed

10°

70°

10°

h

c

t

a

L

h

c

t

a

L

R

a

e

p

e

n

w

g

e

S

D

e

l

a

y

R

a

n

g

e

p

e

e

w

S

Closing Speed ControlsFigure 3

1/8"HexKey1/8"HexKey

SlowIncreaseFastDecrease"L" (Latch)"L" (Latch)"S" (Sweep)"S" (Sweep)"D" (Delayed Action)Standard CloserDelayed Action CloserSweep & LatchDelay

3000 Highway 74 East • Monroe, NC 28112Tel: (877)- • Fax: (800)-338-0965974-2255www.nortondoorcontrols.com

ASSA ABLOY

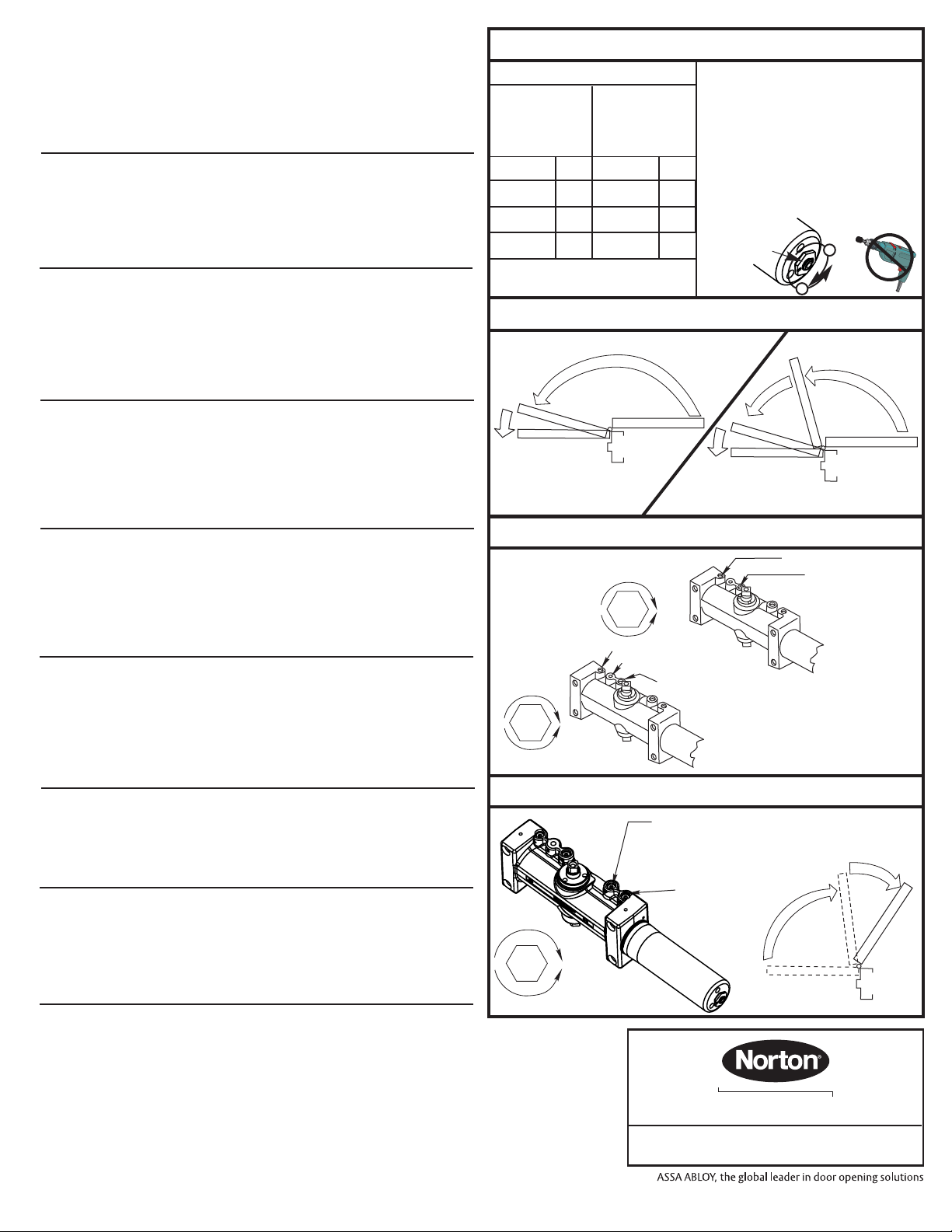

Install closer per instructions with the proper pre-load applied to the arm then adjust spring power. The power adjustment will not work properly if the closer spring is not pre-loaded. To increase power, use 11/16" wrench to turn power adjustment nut clockwise.To decrease power, turn nut counter clockwise.DO NOT use a power drill or driver to turn adjustment nut. This will damage closer and void warranty."Spring PowerAdjustmentNut"+

-

Power Adjustment ChartMaximum InteriorDoor SizeMaximum ExteriorDoor Size30 / (.76) 36 / (.91) 42 / (1.07) NOTE: Maximum of 16-1/2 turns(360°) of Power Adjustment Nut. 48 / (1.22)

inches / (meters)

inches / (meters)

502830 / (.76) 36 / (.91) 42 / (1.07) 48 / (1.22) 82511