2

IP2185EN

Key

This symbol indicates instructions or notes regarding safety, to which special atten-

tion must be paid.

This symbol indicates useful information for the correct functioning of the product.

Contents

General safety precautions .........................................................................................................................................3

EC Declaration of Incorporation ...............................................................................................................................5

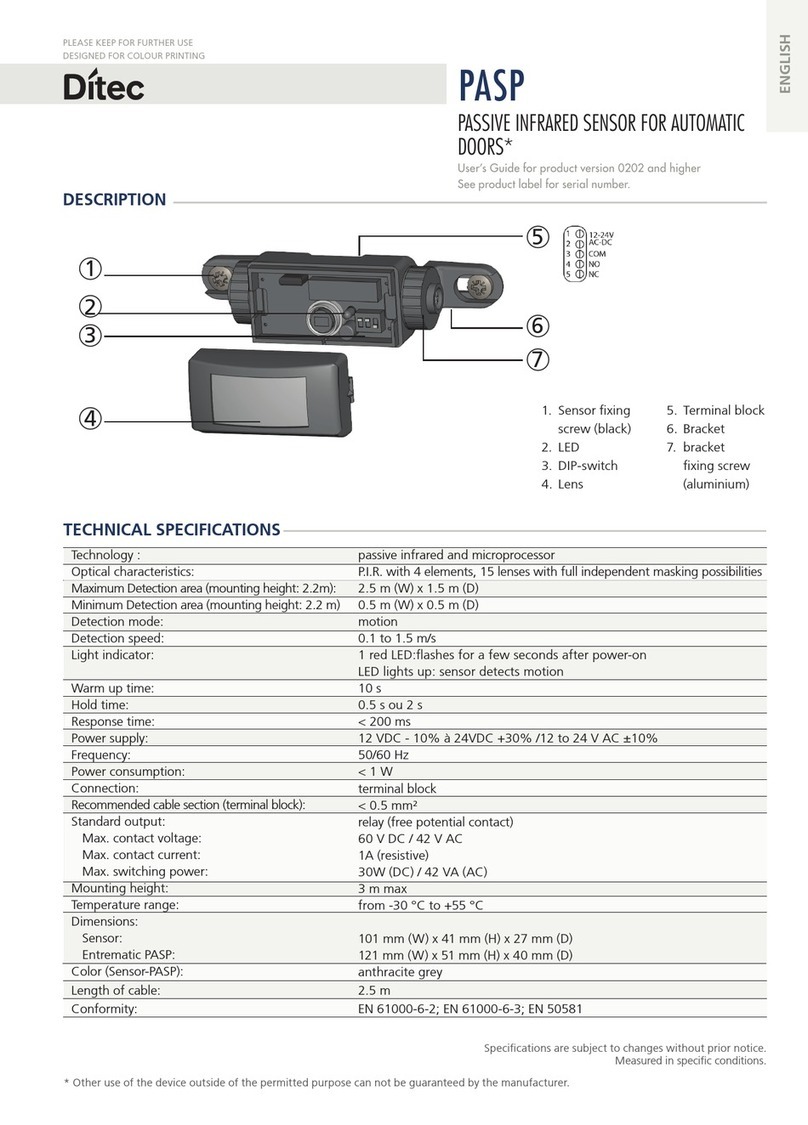

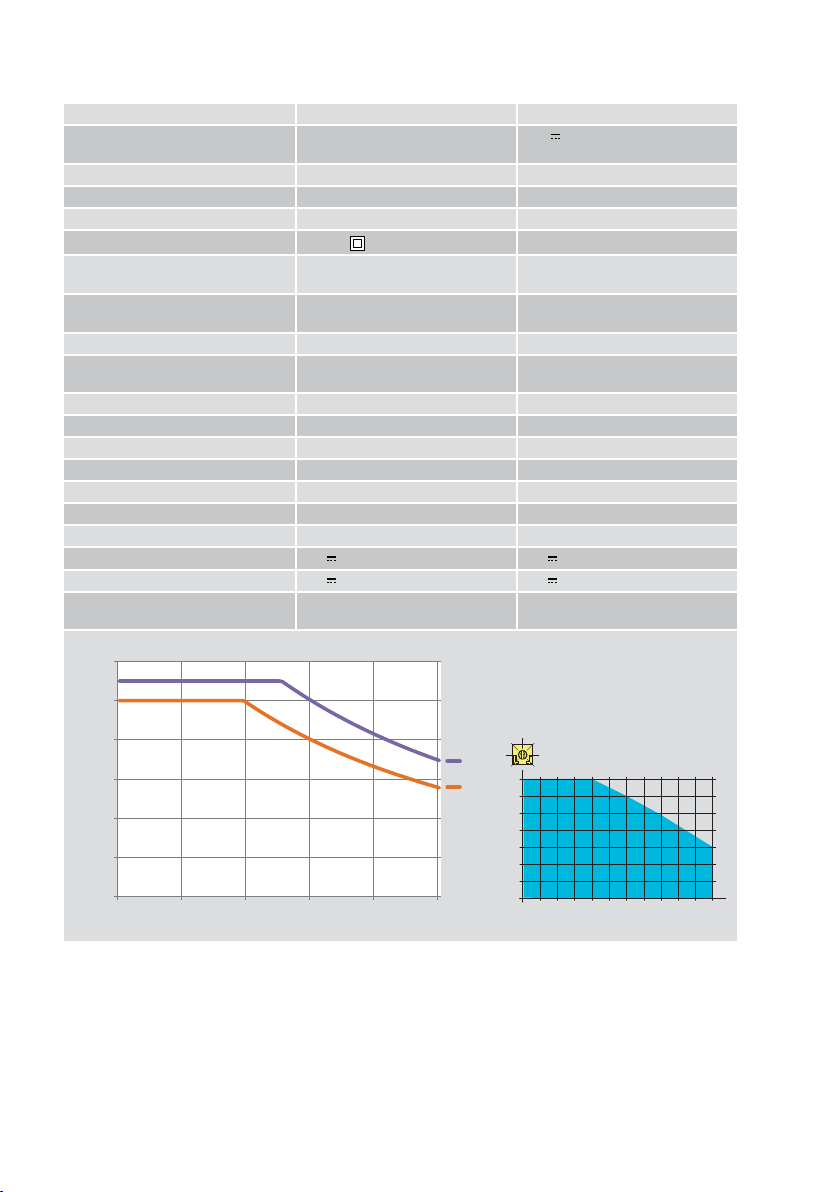

1. Technical specifications ...................................................................................................................................6

1.1 Machinery Directive .................................................................................................................................................7

1.2 Dimensions ...............................................................................................................................................................7

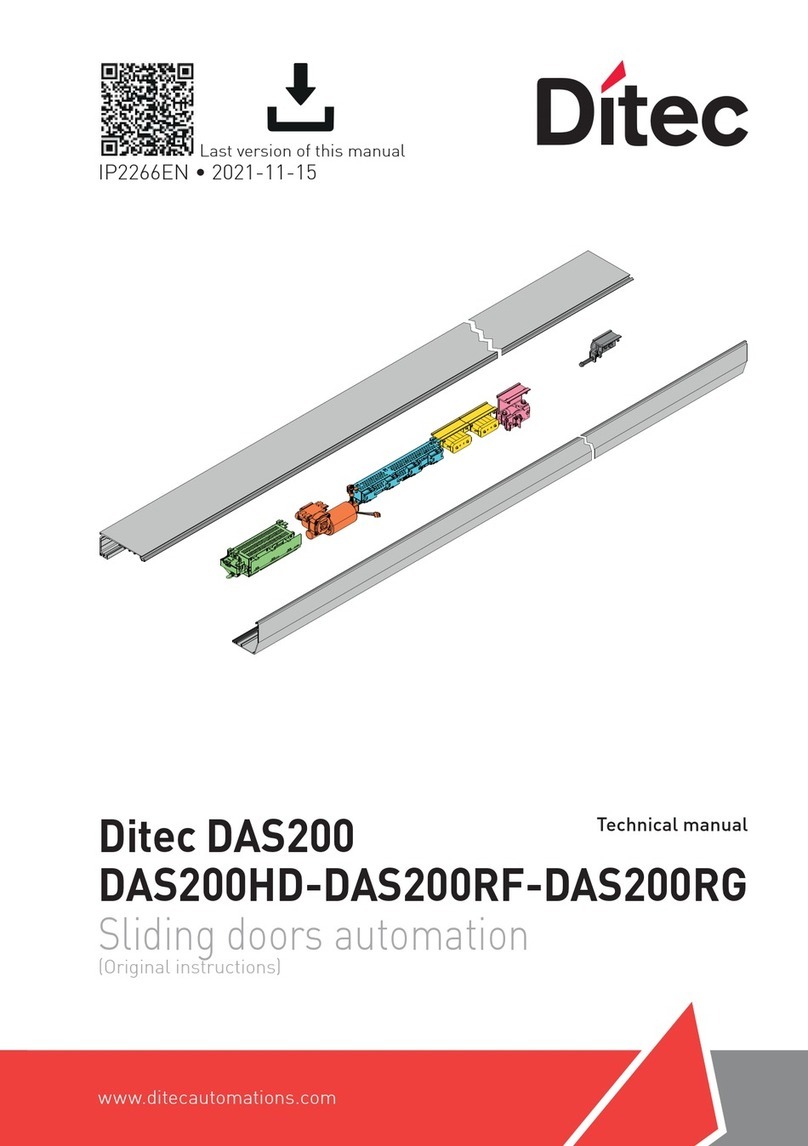

2. Standard installation ......................................................................................................................................8

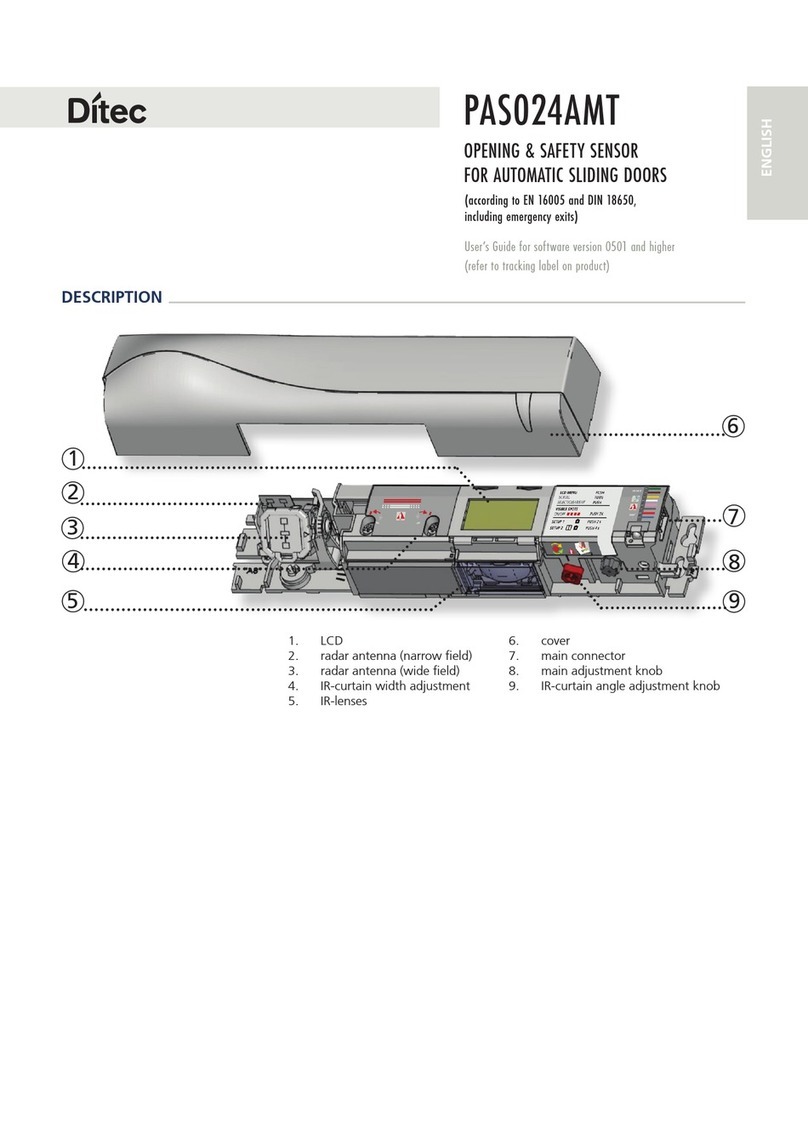

3. Main components ..............................................................................................................................................9

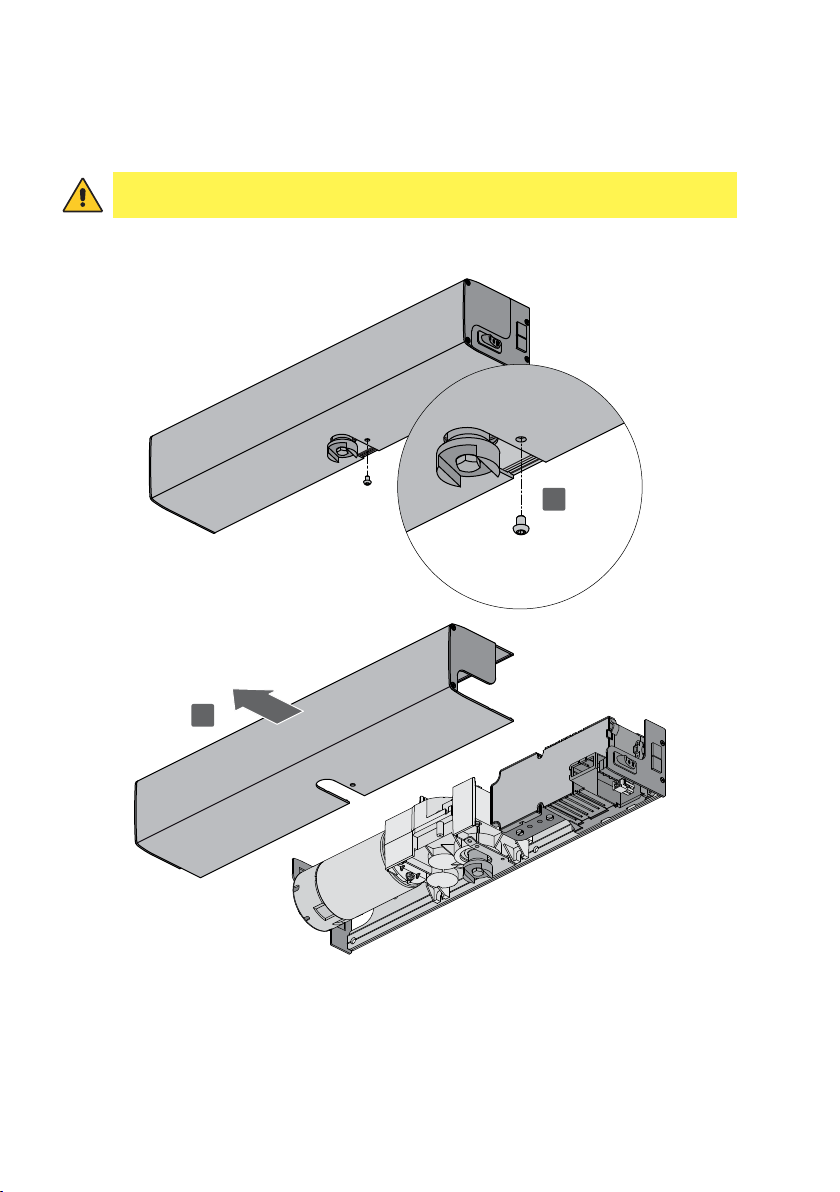

4. Mechanical installation .................................................................................................................................10

4.1 Removing the casing ...........................................................................................................................................10

5. Installation with SBS sliding arm ...............................................................................................................11

6. Installation with SBA articulated arm .............................................................................................................12

7. Installation with SPRINTBRAS 3-lever articulated arm ...........................................................................13

8. Electrical connections ......................................................................................................................................14

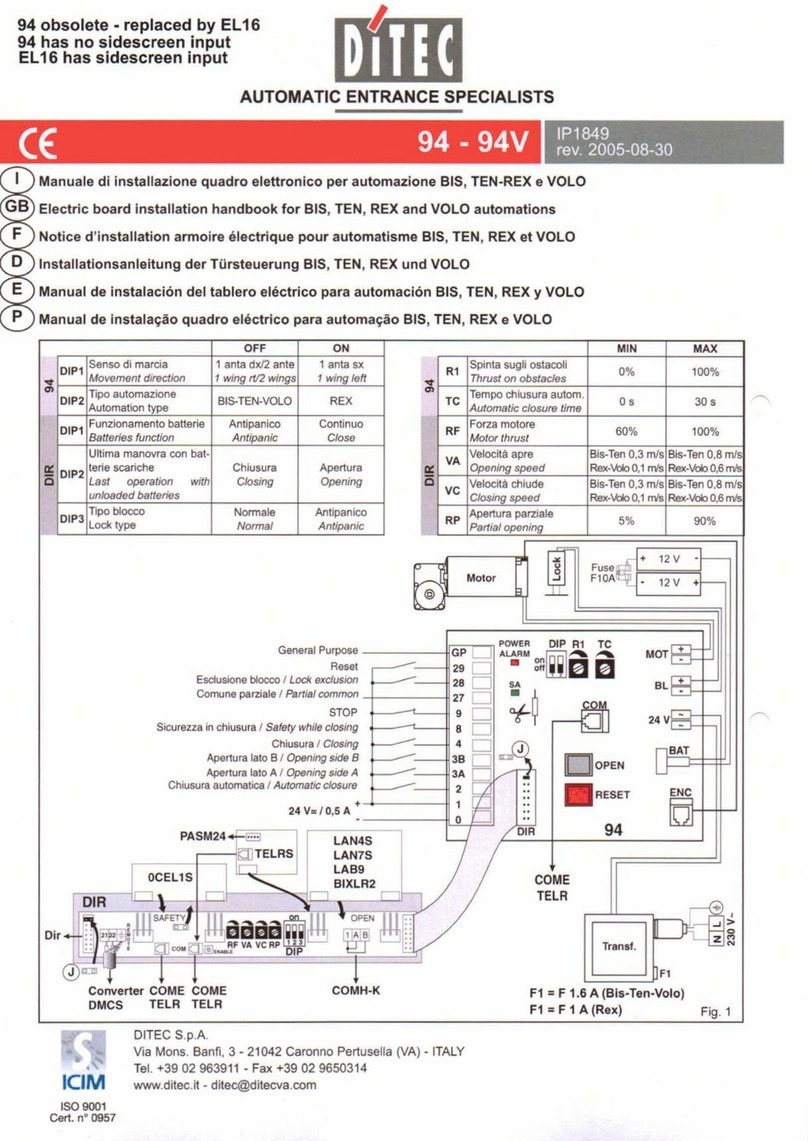

8.1 Electrical connections for 230 V~ power supply .................................................................................................14

8.2 Electrical connections for 24 V power supply ..........................................................................................15

8.3 Electromagnetic emissions ....................................................................................................................................15

9. Connecting the power supply .........................................................................................................................16

10. Commands ......................................................................................................................................................16

10.1 Testable safety devices .........................................................................................................................................16

11. Outputs and accessories ...............................................................................................................................17

11.1 Function selector button ....................................................................................................................................18

11.2 Example of installation with function selector COMH- COMK ................................................................19

11.2.1 Connections PASS24 .............................................................................................................................................................19

11.2.2 Connections REM ...................................................................................................................................................................19

12. Adjustments .....................................................................................................................................................20

12.1 Enabling procedure ..................................................................................................................................................20

12.2 Dip-switches .............................................................................................................................................................20

12.3 Trimmers ..................................................................................................................................................................21

12.4 Signals ......................................................................................................................................................................21

13. Door requisites for Low Energy use .............................................................................................................22

14. Start-up ...........................................................................................................................................................23

15. Troubleshooting ..............................................................................................................................................24

16. Routine maintenance plan ............................................................................................................................25